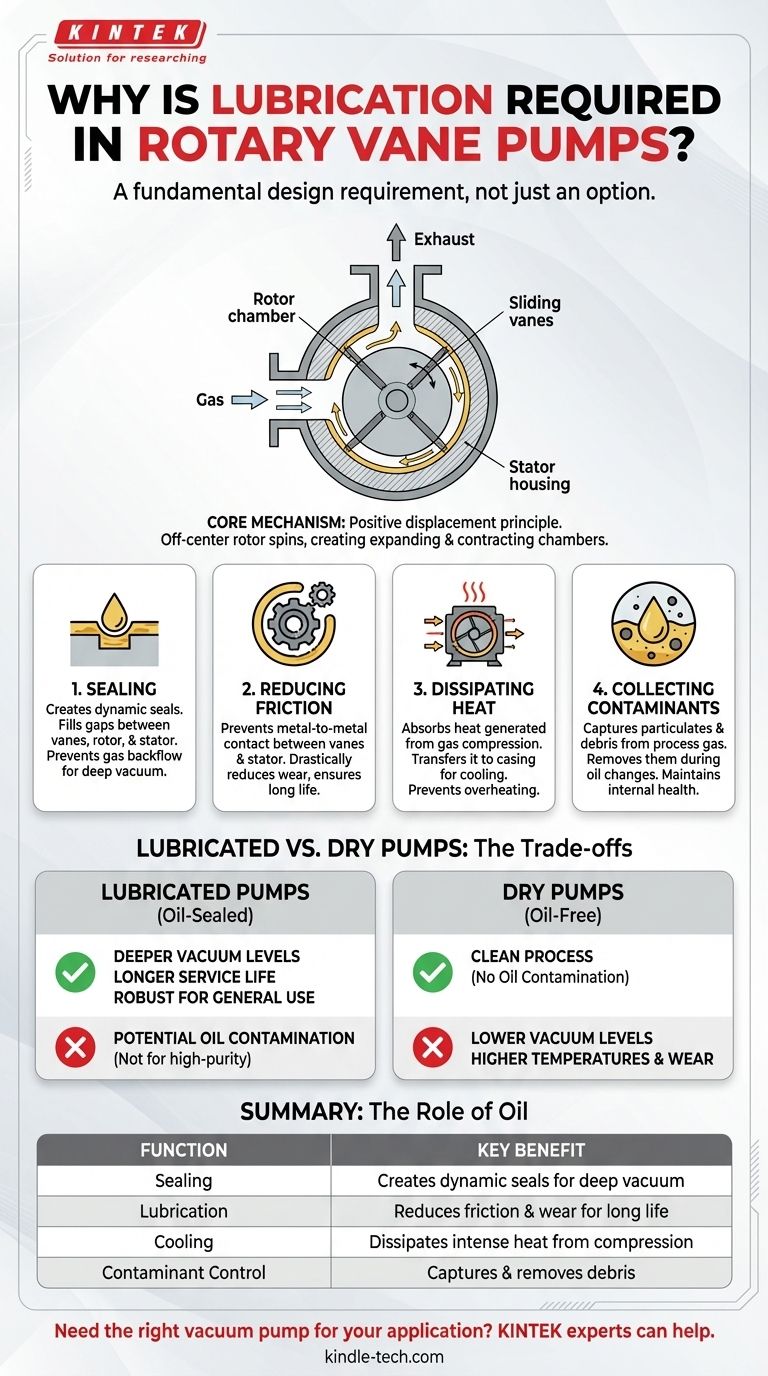

In a rotary vane pump, lubrication is not merely an option but a fundamental design requirement that enables the pump to function. The oil serves three simultaneous and critical purposes: it creates the necessary seals for compression, it removes the intense heat generated during operation, and it prevents catastrophic wear between moving parts.

At its core, the oil in a lubricated rotary vane pump is not just a lubricant. It is a multi-functional fluid that actively participates in the vacuum process by sealing, cooling, and protecting the core mechanism.

The Core Mechanism of a Rotary Vane Pump

To understand why lubrication is so critical, we must first visualize how the pump works. It operates on a principle of positive displacement.

The Key Components

A rotary vane pump consists of a cylindrical housing, known as the stator. Inside this housing, a circular rotor is mounted off-center. This rotor has slots that hold several flat plates called vanes.

Creating Pumping Chambers

As the rotor spins, centrifugal force pushes the vanes outward, keeping their tips in constant contact with the inner wall of the stator. Because the rotor is offset, this creates expanding and contracting chambers between the vanes, rotor, and stator wall.

Gas enters the pump inlet, fills an expanding chamber, and is then sealed off. As the rotor continues to turn, that chamber's volume shrinks, compressing the gas until it is ejected through the exhaust outlet.

The Four Critical Functions of Lubrication

The oil is continuously injected into the pump and forms a thin film on all internal surfaces. This oil film is essential for the entire process.

1. Sealing the Compression Chambers

The primary function of the oil is to create a dynamic seal. It fills the microscopic gaps between the tips of the vanes and the stator wall, between the rotor and the end plates, and between the vanes and their slots. Without this hydraulic seal, gas would leak from the high-pressure side back to the low-pressure side, preventing the pump from achieving a deep vacuum.

2. Reducing Frictional Wear

The vanes are in constant, high-speed sliding contact with the stator wall. The oil film prevents direct metal-to-metal contact, drastically reducing friction and wear. This lubrication is the single most important factor for ensuring a long operational life for the pump.

3. Dissipating the Heat of Compression

Compressing a gas generates a significant amount of heat. This heat is concentrated where the compression occurs. The circulating oil absorbs this thermal energy and carries it away to the pump casing, where it can be dissipated into the surrounding environment. This cooling function prevents the pump from overheating, which could lead to component seizure and oil degradation.

4. Collecting Contaminants

Finally, the circulating oil acts as a cleaning agent. It captures small particulates, debris, and condensed vapors from the process gas, transporting them away from critical clearances. These contaminants are then removed from the system during routine oil changes, maintaining the pump's internal health.

Understanding the Trade-offs: Lubricated vs. Dry Pumps

The necessity of oil in these pumps also introduces a fundamental trade-off: the potential for oil vapor to contaminate the vacuum system. This has led to the development of "dry" or "oil-less" rotary vane pumps.

The Strengths of Lubricated Pumps

Lubricated pumps can achieve deeper vacuum levels and generally have a longer service life precisely because the oil performs the sealing, cooling, and wear-protection functions so effectively. They are robust workhorses for general industrial use.

The Drawback: Oil Contamination

The main limitation is that a small amount of oil vapor will inevitably mix with the pumped gas and exit through the exhaust. This makes standard lubricated pumps unsuitable for high-purity applications, such as in semiconductor manufacturing or mass spectrometry, where even trace amounts of oil can ruin a process.

The Dry Pump Alternative

Dry rotary vane pumps use self-lubricating materials, like graphite composites, for the vanes. They eliminate oil contamination but operate at higher temperatures, experience more wear, and typically cannot achieve the same deep vacuum levels as their oil-sealed counterparts.

Making the Right Choice for Your Application

Choosing between a lubricated and a dry pump depends entirely on the requirements of your process.

- If your primary focus is deep vacuum and long service life: An oil-sealed rotary vane pump is the superior and standard choice for most industrial, packaging, and food processing applications.

- If your primary focus is an absolutely clean, oil-free process: You must use a dry pump and accept the associated trade-offs in performance and longevity.

Understanding that oil is an integral component of the pump's mechanism—not just an additive—is the key to selecting and maintaining the right equipment for your goal.

Summary Table:

| Function of Lubrication | Key Benefit |

|---|---|

| Sealing | Creates dynamic seals for deep vacuum by filling microscopic gaps |

| Lubrication | Reduces friction and wear between vanes and stator for long life |

| Cooling | Dissipates intense heat generated during gas compression |

| Contaminant Control | Captures and removes particulates and condensed vapors |

Need the right vacuum pump for your application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose between lubricated and dry rotary vane pumps based on your specific requirements for vacuum level, cleanliness, and service life. Contact us today to ensure optimal performance and longevity for your laboratory processes!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a magnetron sputtering system? Achieve Superior Thin Film Deposition for Your Lab

- What is the effect of chamber pressure in magnetron sputtering? A Guide to Controlling Film Quality

- What is sintering in manufacturing process? A Guide to Creating Dense, High-Performance Parts

- Is pyrolysis of plastic harmful to the environment? It Depends on How You Manage the Outputs

- Can sintered parts be machined? How to Overcome the Challenges of Porosity

- How does an Ultrafast High-temperature Sintering (UHS) system work? Achieve 3000°C in Seconds

- Can carbon be sputtered? Unlock the Power of Diamond-Like Carbon (DLC) Films

- What is a natural sintering? Uncover the Geological Process That Forms Ore Deposits