In short, a manufacturer's reputation is a critical indicator of the freeze dryer's long-term reliability, performance accuracy, and the quality of support you will receive after the purchase. For a significant capital investment, reputation serves as your primary tool for mitigating risk and ensuring the equipment delivers consistent, trustworthy results for years to come.

A freeze dryer is not a one-time purchase but a long-term investment in your lab's operational success. Choosing a manufacturer based on reputation is about selecting a reliable partner, not just a piece of hardware, thereby minimizing the total cost of ownership and safeguarding your valuable samples.

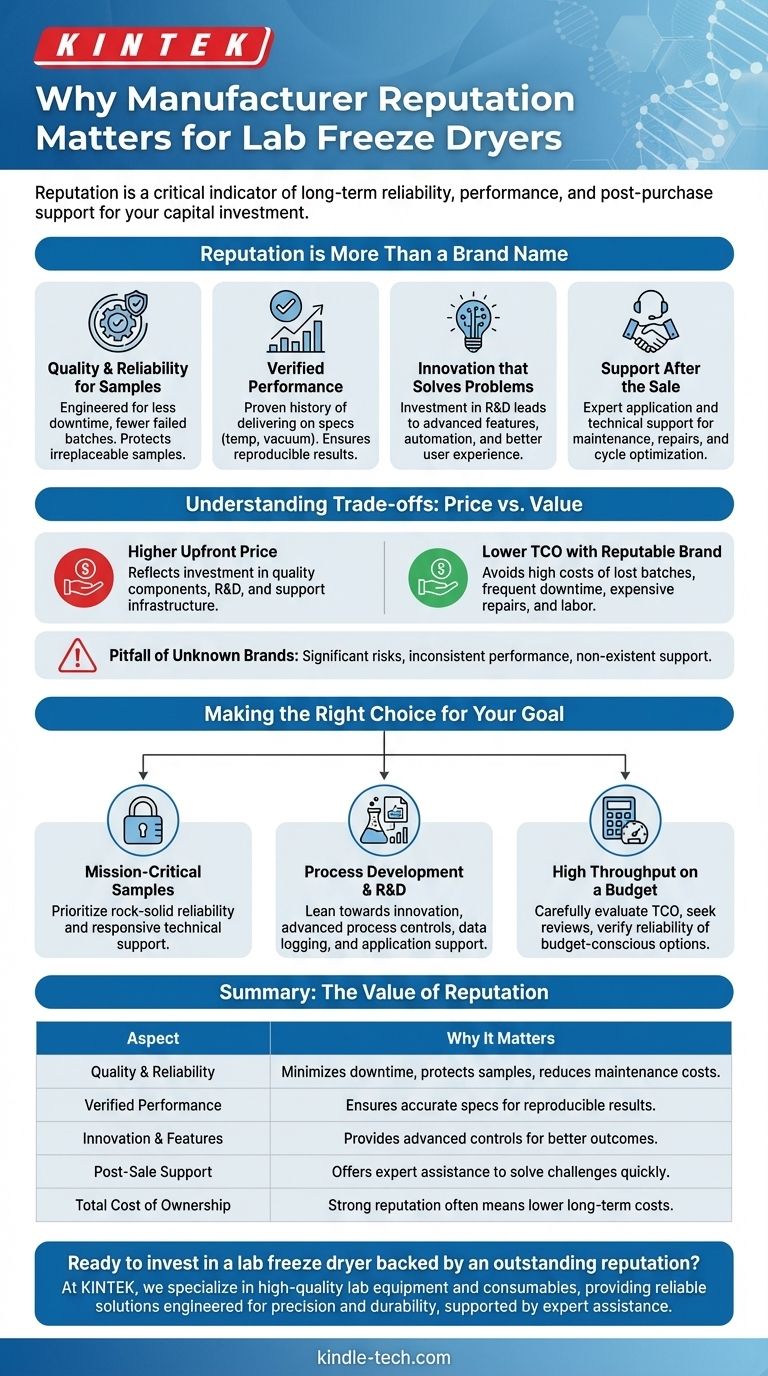

Why Reputation is More Than a Brand Name

When evaluating a lab freeze dryer, it's easy to get lost in technical specifications. However, the manufacturer's reputation provides crucial context for those specifications and predicts the machine's real-world value.

Quality, Reliability, and Your Samples

A reputable manufacturer builds their name on the engineering quality of their equipment. This translates directly into reliability.

A well-built machine means less downtime, fewer failed batches, and lower maintenance costs. Most importantly, it protects your samples, which are often irreplaceable and the result of significant time and expense.

Performance You Can Trust

Reputable brands have a proven history of delivering on their promises. When their spec sheet claims a specific condenser temperature, vacuum level, or shelf temperature uniformity, you can be more confident in its accuracy.

This verified performance is essential for developing reproducible lyophilization cycles and ensuring the integrity of sensitive biological or pharmaceutical products.

Innovation That Solves Problems

Established manufacturers invest heavily in research and development. This leads to meaningful innovations that improve process control and user experience.

Features like advanced automation, sophisticated data logging for regulatory compliance, and more efficient cooling systems are often hallmarks of a leading brand. These features aren't just "frills"; they are tools that expand your application range and improve results.

Support After the Sale

The relationship with your manufacturer doesn't end at delivery. A complex piece of equipment like a freeze dryer requires expert support.

Reputable companies provide both application support to help you optimize freeze-drying cycles for your specific product and technical support for maintenance and repairs. This partnership is invaluable when you encounter a challenge.

Understanding the Trade-offs

A strong reputation often comes with a higher price tag. It is crucial to understand the financial implications and weigh them against the potential risks.

Upfront Cost vs. Total Cost of Ownership

Established brands typically command higher prices. This premium reflects their investment in quality components, R&D, and robust support infrastructure.

However, a lower-priced machine from an unproven manufacturer can have a much higher Total Cost of Ownership (TCO). Factor in the costs of lost batches, frequent downtime, expensive repairs, and the labor required to manage an unreliable machine.

The Pitfalls of an Unknown Brand

Opting for a lesser-known manufacturer can introduce significant risks. These may include inconsistent performance, difficulty sourcing replacement parts, and non-existent customer or application support.

When a machine goes down and you cannot get timely help, your lab's entire workflow can grind to a halt, making the initial savings insignificant.

Matching Reputation to Your Actual Needs

While vital, reputation shouldn't be the only factor. The best manufacturer for one application may not be right for another.

Prioritize the features essential for your work. If precise shelf temperature control is critical for your sensitive samples, focus on manufacturers renowned for their temperature management systems, even if you must forego other advanced features.

Making the Right Choice for Your Goal

Your final decision should balance reputation with your specific application, throughput, and budget.

- If your primary focus is mission-critical samples: Prioritize manufacturers with a rock-solid reputation for reliability and responsive technical support to protect your work above all else.

- If your primary focus is process development and R&D: Lean towards innovative manufacturers known for advanced process controls, data logging, and strong application support.

- If your primary focus is high throughput on a budget: Carefully evaluate the total cost of ownership, and seek reviews or recommendations from other users in your field to verify the reliability of a more budget-conscious option.

Ultimately, selecting the right manufacturer is about ensuring your investment empowers your research for its entire operational life.

Summary Table:

| Aspect | Why It Matters |

|---|---|

| Quality & Reliability | Minimizes downtime, protects irreplaceable samples, and reduces maintenance costs. |

| Verified Performance | Ensures accurate specifications for reproducible results and sample integrity. |

| Innovation & Features | Provides advanced controls, data logging, and efficient systems for better outcomes. |

| Post-Sale Support | Offers expert technical and application support to solve challenges quickly. |

| Total Cost of Ownership | A strong reputation often means lower long-term costs despite a higher initial price. |

Ready to invest in a lab freeze dryer backed by an outstanding reputation?

At KINTEK, we specialize in high-quality lab equipment and consumables, serving laboratories with reliable solutions. Our freeze dryers are engineered for precision, durability, and supported by expert technical and application assistance to safeguard your research.

Don't leave your valuable samples to chance—contact us today to discuss how a KINTEK freeze dryer can become a trusted partner in your lab's success!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the main steps involved in the freeze-drying process? A Guide to the 3 Key Stages

- What is a Laboratory Freeze Dryer and what is its primary function? Achieve Perfect Preservation of Sensitive Materials

- What is the role of the refrigeration system in a freeze dryer? It's the Heart of the Sublimation Process

- How can budgetary constraints be managed when purchasing a lab freeze dryer? A Strategic Guide to Cost-Effective Investment

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation