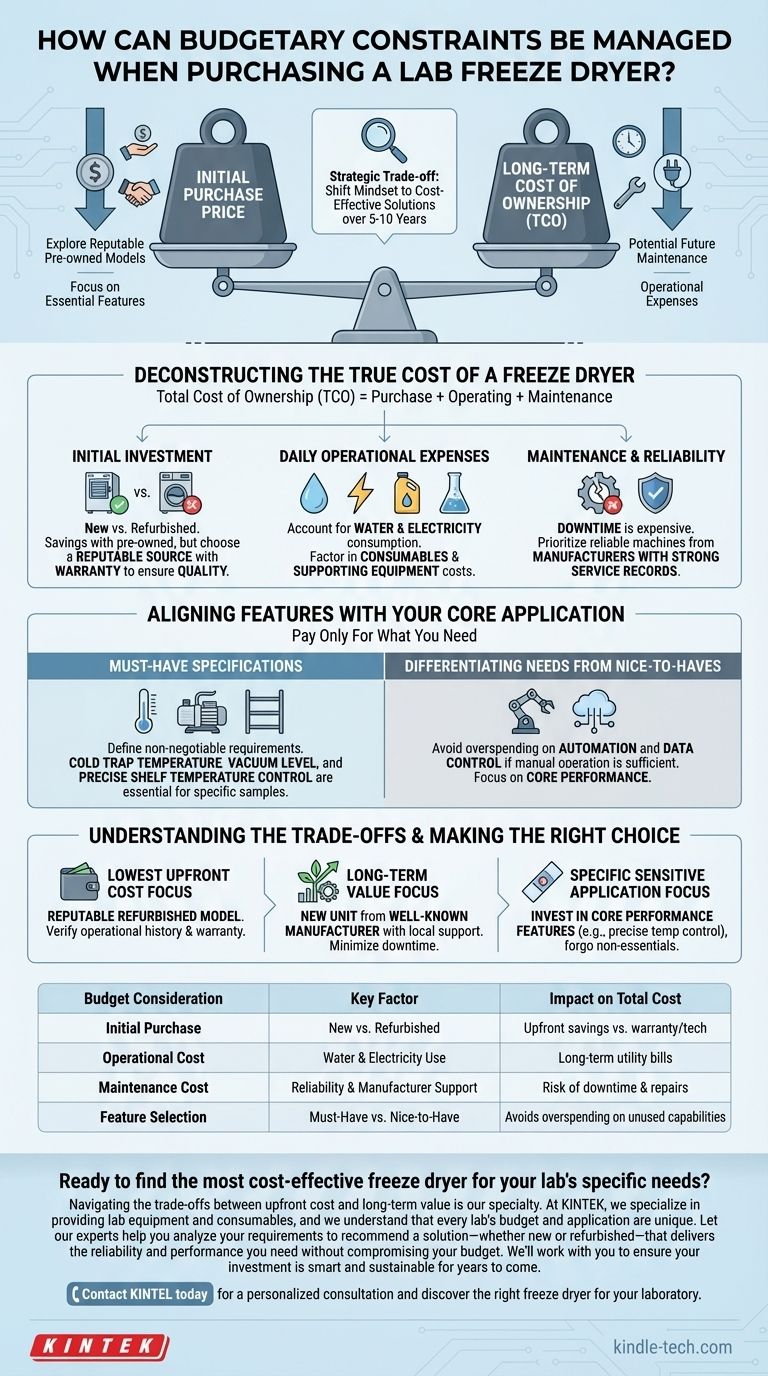

At its core, managing a freeze dryer purchase on a tight budget involves a strategic trade-off between the initial purchase price and the long-term cost of ownership. You can achieve significant upfront savings by exploring reputable pre-owned models and focusing only on features essential to your application, but this must be balanced against potential future maintenance and operational expenses.

The most critical shift in mindset is from "What is the cheapest freeze dryer I can buy?" to "What is the most cost-effective solution for my specific application over the next 5-10 years?" The sticker price is only one component of the total investment.

Deconstructing the True Cost of a Freeze Dryer

A smart budgetary decision looks beyond the initial quote. The true cost of a freeze dryer—its total cost of ownership (TCO)—is a combination of the purchase price, daily operating costs, and long-term maintenance.

Beyond the Sticker Price: The Initial Investment

Your first decision point is whether to buy new or used. Pre-owned or refurbished models can offer substantial cost savings, making them a valid option for budget-conscious labs.

However, it is crucial to purchase from a reputable source that can verify the unit's performance and potentially offer a limited warranty. Quality and reliability should never be the primary compromise.

The Hidden Costs: Daily Operational Expenses

A freeze dryer's impact on your budget doesn't end after the purchase. You must account for ongoing costs.

Consider the water and electricity consumption of the unit. A less efficient model might be cheaper upfront but cost significantly more in utility bills over its lifespan.

Also, factor in the costs of consumables and supporting equipment, such as vacuum pump oil and glassware, which are necessary for operation.

The Price of Failure: Maintenance and Reliability

Downtime is expensive. A failed experiment or a broken machine can cost far more than the initial savings on a cheaper unit.

This is why the manufacturer's reputation is a critical budget consideration. A reliable machine from a company with a strong service record minimizes the risk of costly repairs and protects your research.

Aligning Features with Your Core Application

The key to controlling costs is to pay only for what you absolutely need. Avoid the temptation of advanced features that don't directly support your primary workflow.

Identify Your "Must-Have" Specifications

Begin by defining your non-negotiable requirements. This is dictated by your samples and process.

Key technical specifications include the cold trap temperature, which must be cold enough to trap your specific solvents, and the vacuum level, which dictates drying efficiency.

If you work with sensitive biological samples, precise shelf temperature control is not a luxury—it is an essential feature to ensure product viability.

Differentiating Needs from 'Nice-to-Haves'

Many modern freeze dryers offer sophisticated automation and data-logging features.

Ask yourself if this level of automation and data control is critical for your compliance or throughput needs. If manual operation and logging are sufficient, you can opt for a simpler, less expensive model.

Understanding the Trade-offs

Every budgetary decision involves compromise. Being aware of the potential pitfalls is essential for making an informed choice.

The New vs. Refurbished Dilemma

A new machine offers the latest technology, a full manufacturer's warranty, and the longest potential lifespan. A refurbished unit trades these benefits for a significantly lower upfront cost, but may carry a higher risk of future maintenance issues.

The Pitfall of "Over-Specing"

Paying for capabilities you will never use is the most direct way to waste your budget. A freeze dryer with an unnecessarily low cold trap temperature or excessive capacity for your sample volume is an inefficient use of capital.

The Danger of "Under-Specing"

The most expensive mistake is buying a machine that cannot do the job. A freeze dryer that is too small, not cold enough for your solvents, or lacks the control you need will lead to failed batches and the eventual need for a premature—and costly—replacement.

Making the Right Choice for Your Goal

Your final decision should be guided by a clear understanding of your primary objective.

- If your primary focus is the lowest possible upfront cost: Seek out a reputable refurbished model, but rigorously verify its operational history and any available warranty.

- If your primary focus is long-term value and reliability: Prioritize a new unit from a well-known manufacturer with strong local support, as this minimizes the risk of expensive downtime.

- If your primary focus is a highly specific, sensitive application: Invest your budget in the core performance features that protect your samples, such as precise temperature control, and forgo other non-essential bells and whistles.

Ultimately, this strategic evaluation ensures your budget is not just spent, but invested wisely for the long-term success of your lab.

Summary Table:

| Budget Consideration | Key Factor | Impact on Total Cost |

|---|---|---|

| Initial Purchase | New vs. Refurbished | Upfront savings vs. warranty/tech |

| Operational Cost | Water & Electricity Use | Long-term utility bills |

| Maintenance Cost | Reliability & Manufacturer Support | Risk of downtime & repairs |

| Feature Selection | Must-Have vs. Nice-to-Have | Avoids overspending on unused capabilities |

Ready to find the most cost-effective freeze dryer for your lab's specific needs?

Navigating the trade-offs between upfront cost and long-term value is our specialty. At KINTEK, we specialize in providing lab equipment and consumables, and we understand that every lab's budget and application are unique.

Let our experts help you analyze your requirements to recommend a solution—whether new or refurbished—that delivers the reliability and performance you need without compromising your budget. We'll work with you to ensure your investment is smart and sustainable for years to come.

Contact KINTEL today for a personalized consultation and discover the right freeze dryer for your laboratory.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- What is the purpose of an evaporator? The Key Component That Creates Cooling