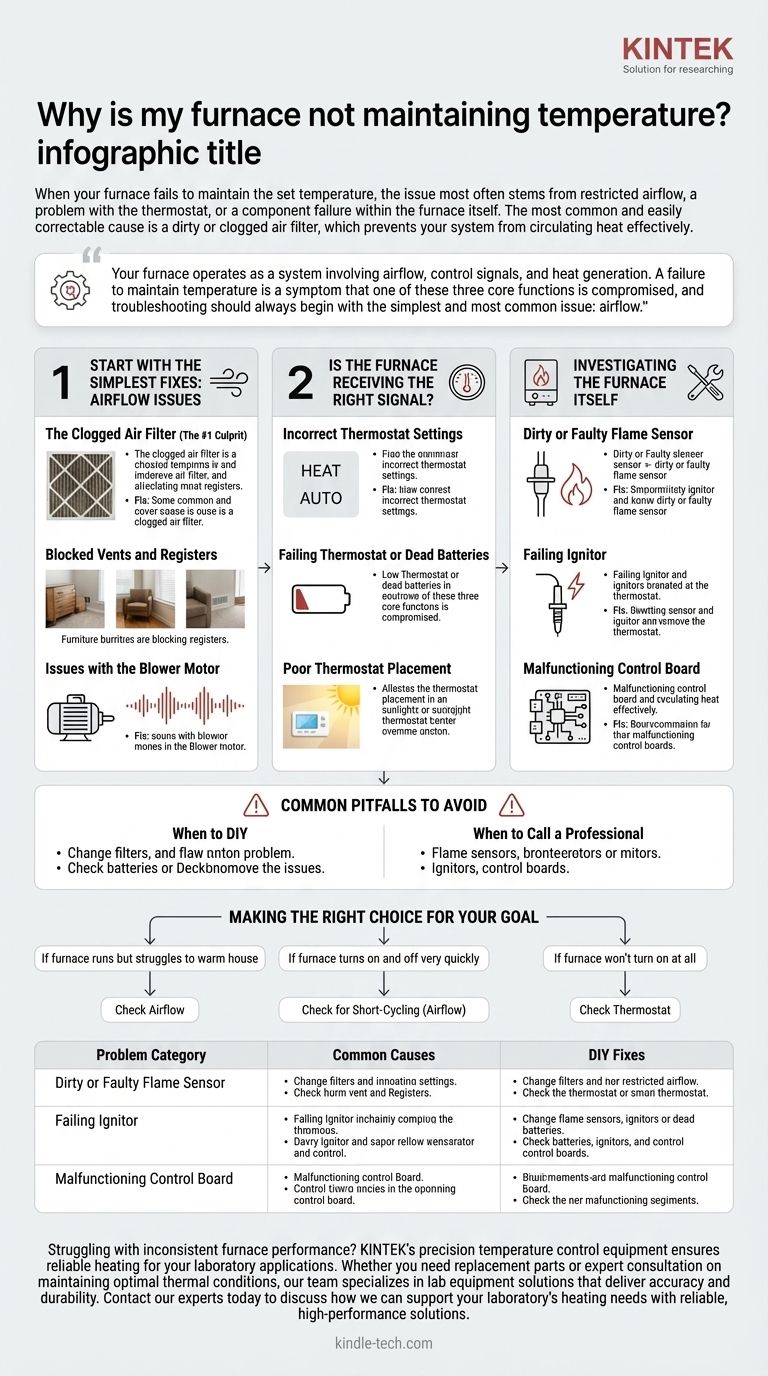

When your furnace fails to maintain the set temperature, the issue most often stems from restricted airflow, a problem with the thermostat, or a component failure within the furnace itself. The most common and easily correctable cause is a dirty or clogged air filter, which prevents your system from circulating heat effectively.

Your furnace operates as a system involving airflow, control signals, and heat generation. A failure to maintain temperature is a symptom that one of these three core functions is compromised, and troubleshooting should always begin with the simplest and most common issue: airflow.

Start with the Simplest Fixes: Airflow Issues

Before suspecting a major mechanical failure, you must verify that air can move freely through your heating system. Airflow problems are the leading cause of furnace inefficiency and short-cycling, where the unit turns on and off rapidly without reaching the target temperature.

The Clogged Air Filter (The #1 Culprit)

A dirty filter is the most frequent reason a furnace underperforms. It forces the blower motor to work harder and can restrict the volume of warm air delivered to your rooms.

This can also cause the furnace's heat exchanger to overheat, triggering a safety switch that shuts the system down prematurely. You should inspect and, if necessary, replace your air filter immediately.

Blocked Vents and Registers

Ensure that furniture, rugs, or curtains are not blocking the supply and return air vents in your home. Each blocked vent reduces the overall efficiency of the system and can create temperature imbalances.

Issues with the Blower Motor

While less common, a failing blower motor can't push enough air across the heat exchanger. You might hear unusual noises or notice significantly weaker airflow from your vents, even with a clean filter.

Is the Furnace Receiving the Right Signal?

If airflow is not the issue, the next step is to check the system's "brain"—the thermostat. It tells your furnace when to turn on, how hot to get, and when to shut off.

Incorrect Thermostat Settings

First, confirm the basics. Ensure your thermostat is set to "Heat" and the fan is set to "Auto," not "On." A fan set to "On" will blow air continuously, even when the furnace isn't actively heating, making the air feel cool.

Failing Thermostat or Dead Batteries

A thermostat with low batteries can send erratic signals or fail to communicate with the furnace altogether. Replace the batteries if applicable.

If the thermostat itself is old or malfunctioning, it may not be accurately reading the room's temperature, causing it to shut the furnace off too early.

Poor Thermostat Placement

If your thermostat is located in direct sunlight, near a draft, or next to another heat source (like a lamp or television), it will get a false temperature reading. This can trick it into thinking the room is warmer than it is, preventing it from calling for heat when needed.

Investigating the Furnace Itself

If you have confirmed that airflow is good and the thermostat is working correctly, the problem likely lies within the furnace unit. These issues are more complex and often require professional diagnosis.

Dirty or Faulty Flame Sensor

In a gas furnace, the flame sensor is a critical safety device that confirms a flame is present. If this sensor becomes coated in soot or corrosion, it can't detect the flame and will shut off the gas valve as a precaution, stopping the heating cycle.

Failing Ignitor

The ignitor is the component that lights the gas in your furnace. If it's cracked or failing, the furnace burners won't light, and the system will shut down after attempting to start. You may hear a "click" but never the "whoosh" of the burners igniting.

Malfunctioning Control Board

The furnace's control board is the central hub that coordinates all its operations, from the thermostat signal to the ignitor and blower motor. A failure in the control board can lead to a wide range of unpredictable behaviors, including not maintaining temperature.

Common Pitfalls to Avoid

Diagnosing a furnace can be straightforward, but it's critical to know the limits of a do-it-yourself approach. Missteps can be costly or, in the case of gas and high-voltage electrical components, dangerous.

When to DIY

Homeowners can and should regularly handle tasks like changing the air filter, checking thermostat batteries and settings, and clearing blocked vents. These simple maintenance steps solve the majority of furnace performance issues.

When to Call a Professional

Any issue requiring you to open the main furnace panels should be handled by a qualified HVAC technician. This includes cleaning or replacing a flame sensor, testing an ignitor, or diagnosing a control board. Working with gas lines and high-voltage electrical systems is not a DIY task.

Making the Right Choice for Your Goal

Use this logic to guide your actions, starting with the easiest and safest steps first.

- If your furnace runs but struggles to warm the house: Your first suspect should be airflow; check the filter and ensure all vents are open and unobstructed.

- If your furnace turns on and off very quickly: This is likely "short-cycling," caused by restricted airflow making the furnace overheat, so check the air filter immediately.

- If your furnace won't turn on at all: Start by checking the thermostat batteries and settings before suspecting a more serious component failure like the ignitor.

By systematically ruling out the simple causes first, you can solve many problems yourself and provide valuable information to a technician if you need to call one.

Summary Table:

| Problem Category | Common Causes | DIY Fixes |

|---|---|---|

| Airflow Issues | Clogged air filter, blocked vents, failing blower motor | Replace filter, clear vents |

| Thermostat Problems | Incorrect settings, dead batteries, poor placement | Check settings, replace batteries |

| Furnace Component Failure | Dirty flame sensor, failing ignitor, control board issues | Professional diagnosis required |

Struggling with inconsistent furnace performance? KINTEK's precision temperature control equipment ensures reliable heating for your laboratory applications. Whether you need replacement parts or expert consultation on maintaining optimal thermal conditions, our team specializes in lab equipment solutions that deliver accuracy and durability. Contact our experts today to discuss how we can support your laboratory's heating needs with reliable, high-performance solutions.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the hottest temperature a furnace can be? Exploring Limits from 3,000°C+ to Your Application

- What is the purpose of a muffle furnace? Achieve Pure, Contamination-Free High-Temperature Heating

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control

- What is the difference between muffle furnace and air oven? Choose the Right Tool for Your Thermal Process

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage