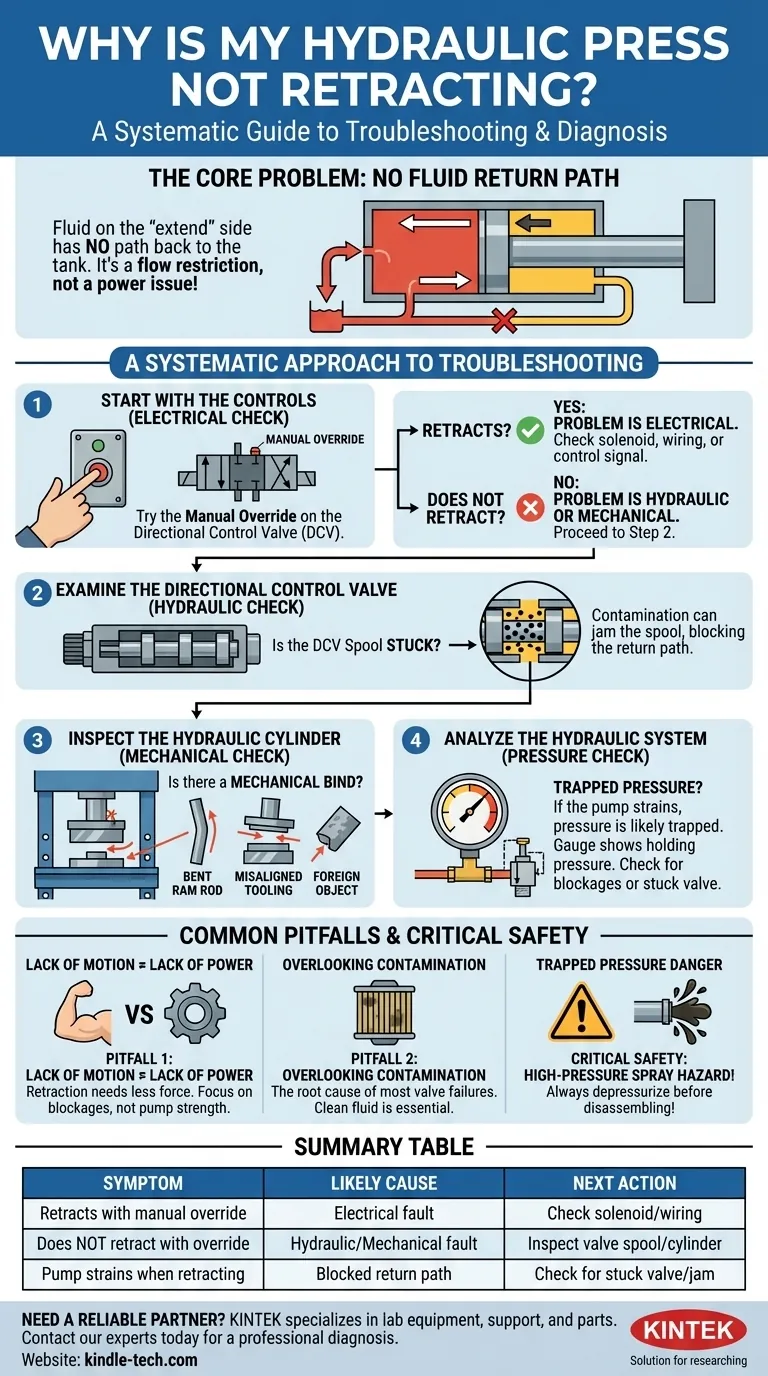

The most likely reason your hydraulic press is not retracting is a problem with the directional control valve, a mechanical jam in the cylinder itself, or trapped pressure preventing the ram from moving. These issues all stem from a single principle: the hydraulic fluid on the "extend" side of the piston has no path back to the tank.

Your core task is not to force the press to retract, but to find what is blocking the fluid's return path. A failure to retract is almost always a problem of restricted fluid flow, not a lack of power.

A Systematic Approach to Troubleshooting

When a press fails to retract, the cause can be electrical, hydraulic, or mechanical. A methodical approach, starting with the simplest and safest checks, is the most efficient way to identify the root cause.

Start with the Controls (The Easiest Check)

Before inspecting any hydraulic components, verify the control system is sending the correct signal. This isolates electrical issues from the rest of the system.

Many directional valves have a manual override. This is typically a small, protected button you can push with a tool to physically shift the valve's internal spool. If the press retracts when you use the manual override, the problem is almost certainly electrical—a failed solenoid coil, bad wiring, or no signal from the PLC or operator button.

Examine the Directional Control Valve (The Traffic Cop)

The directional control valve (DCV) is the most common point of failure. Its job is to direct the flow of fluid, either to extend the ram or retract it.

A stuck valve spool is a primary suspect. The spool is a precision-machined part that slides inside the valve body. Contamination in the hydraulic fluid can cause this spool to jam, preventing it from shifting to the "retract" position. Even if the solenoid receives power, a stuck spool will keep the return path blocked.

Inspect the Hydraulic Cylinder (The Mechanical Link)

The problem may not be hydraulic at all. A severe mechanical bind can physically prevent the ram from moving, regardless of hydraulic commands.

Visually inspect the ram and the tooling. A bent ram rod, misaligned tooling, or a foreign object in the press can create enough side-load to jam the cylinder's piston and seals against the cylinder wall.

Analyze the Hydraulic System (Pressure and Flow)

The health of the entire system plays a critical role. The symptom might be at the cylinder, but the cause could be elsewhere.

The core issue is often trapped pressure. When the directional valve fails to shift, the fluid that was used to extend the ram is now trapped in the cylinder and the connecting hose. The pump has no ability to overcome this locked volume of fluid. Gauges can help confirm if pressure is holding where it shouldn't be.

Common Pitfalls in Diagnosis

An incorrect assumption can lead to wasted time and unnecessary component replacement. Avoiding these common mistakes is key to an accurate diagnosis.

Mistaking a Lack of Motion for a Lack of Power

It is tempting to think the pump isn't "strong enough" to pull the ram back. In reality, retraction typically requires far less force than extension. The problem is a hydraulic or mechanical "lock" that is preventing movement.

Overlooking Contamination as the Root Cause

Replacing a stuck directional valve will fix the immediate problem. However, if you don't address the dirty fluid that caused it to fail, the new valve will eventually suffer the same fate. Contamination is the leading cause of hydraulic component failure.

The Danger of Trapped Pressure

This is a critical safety warning. If the system is holding trapped pressure, loosening a hydraulic fitting can result in a high-velocity spray of hot oil, which can cause severe injury. Always verify the system is de-pressurized before attempting to disassemble any components.

A Practical Diagnostic Workflow

Follow these steps to safely and efficiently identify the issue.

- If your press retracts using the manual valve override: Your problem is electrical. Focus on the solenoid coil, wiring, and control signals.

- If your press does NOT retract with the manual override: Your problem is hydraulic or mechanical. The valve spool is likely stuck, a line is blocked, or the cylinder is in a bind.

- If you hear the pump straining when you command retraction: This often indicates the system is building pressure against a blocked path and going over the relief valve. This points strongly to a stuck valve or a mechanical jam.

- Before working on any component: Always follow proper lock-out/tag-out procedures and confirm all system pressure has been safely relieved.

By methodically isolating the electrical, hydraulic, and mechanical systems, you can pinpoint the exact cause of the failure and restore your equipment safely.

Summary Table:

| Symptom | Likely Cause | Next Action |

|---|---|---|

| Retracts with manual valve override | Electrical fault (solenoid, wiring, PLC) | Check solenoid coil and control signals |

| Does NOT retract with manual override | Hydraulic/Mechanical fault (stuck valve, jam) | Inspect valve spool and cylinder for binding |

| Pump strains when retracting | Blocked fluid return path | Check for stuck valve or mechanical jam |

Need a reliable partner for your lab's hydraulic press maintenance? KINTEK specializes in lab equipment and consumables, offering expert support and high-quality replacement parts to keep your operations running smoothly. Don't let downtime disrupt your workflow—contact our experts today for a professional diagnosis and solution tailored to your laboratory's needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation