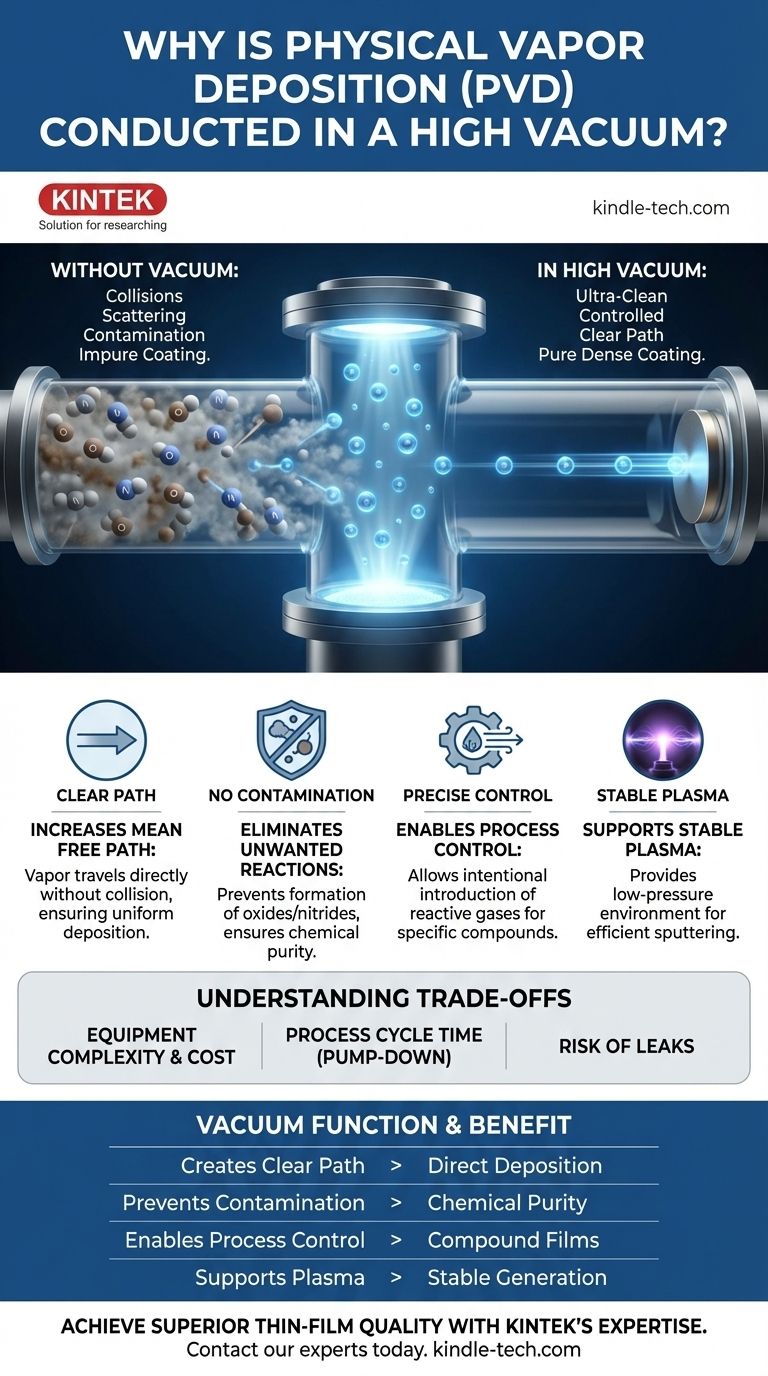

In short, Physical Vapor Deposition (PVD) is conducted in a high vacuum to create an ultra-clean, controlled environment. The vacuum removes virtually all air and other gas molecules from the processing chamber. This ensures that vaporized coating particles can travel directly from their source to the target component without colliding with anything or reacting with unwanted contaminants, which is essential for creating a pure, dense, high-performance coating.

The core purpose of the vacuum in PVD is to clear a "highway" for vaporized material. By removing the "traffic" of air and contaminant molecules, the vacuum prevents collisions and unwanted chemical reactions, ensuring the coating material arrives at its destination purely and with enough energy to form a superior film.

The Critical Functions of the Vacuum Environment

A high vacuum isn't just a passive condition; it actively enables the entire PVD process. Without it, depositing a high-quality thin film would be impossible.

To Create a "Clear Path" for Deposition

The most fundamental reason for a vacuum is to increase the mean free path of the vapor particles. This term refers to the average distance a particle can travel before colliding with another particle.

At normal atmospheric pressure, the air is dense with molecules. A vaporized coating particle would only travel a microscopic distance before colliding with an air molecule, scattering it and preventing it from ever reaching the target surface.

A high vacuum removes these obstacles. This allows the vaporized particles to travel in a straight, uninterrupted line-of-sight from the source material to the substrate, which is crucial for building a uniform coating.

To Eliminate Contamination and Unwanted Reactions

The air we breathe is about 78% nitrogen and 21% oxygen, both of which are highly reactive, especially with the hot, energetic materials used in PVD.

If these atmospheric gases were present, they would immediately react with the vaporized metal. This would form unintended and undesirable oxides and nitrides within the coating, compromising its purity, structural integrity, and performance characteristics.

The vacuum ensures the only material being deposited is the intended source material, resulting in a chemically pure film.

To Enable Precise Process Control

By removing all existing gases, the vacuum creates a perfectly clean slate. This gives engineers complete control over the chamber's atmosphere.

If the goal is to create a specific compound coating, such as Titanium Nitride (TiN) or an oxide, a precise amount of a reactive gas (like nitrogen or oxygen) can be intentionally introduced into the chamber.

The vacuum environment ensures that this introduced gas is the only thing the vaporized metal can react with, allowing for the creation of highly specialized films with exact chemical compositions.

To Support a Stable Plasma Environment

Many PVD techniques, such as sputtering, rely on generating a plasma within the chamber to bombard the source material and eject atoms.

A stable, low-temperature plasma can only be initiated and sustained in a low-pressure environment. The vacuum provides the necessary conditions for this critical step in the process.

Understanding the Practical Trade-offs

While essential, operating in a high vacuum introduces specific engineering and operational challenges.

Equipment Complexity and Cost

Achieving and maintaining a high vacuum requires sophisticated and expensive equipment. This includes a series of pumps (like turbo-molecular and cryogenic pumps) and a robustly built chamber capable of withstanding immense external atmospheric pressure.

Process Cycle Time

Evacuating a chamber to the required vacuum level is not instantaneous. This "pump-down" time can be a significant portion of the overall process cycle, which directly impacts manufacturing throughput and productivity.

Risk of Leaks

The integrity of the vacuum system is paramount. Even a microscopic leak can introduce contaminants, disrupt the plasma, and ruin the quality of the coating. This demands meticulous system design and regular maintenance to prevent process failure.

Making the Right Choice for Your Goal

The vacuum is the foundation upon which PVD's key benefits are built. Understanding its role helps clarify why the process is chosen for specific applications.

- If your primary focus is material purity: The high vacuum is non-negotiable, as it is the only way to prevent contamination from atmospheric gases and ensure the deposited film has the intended chemical composition.

- If your primary focus is a dense, adherent coating: The vacuum's role in ensuring a long mean free path is critical, as it allows particles to arrive at the substrate with enough energy to form a tightly packed, well-adhered layer.

- If your primary focus is creating specialized compound films (e.g., oxides or nitrides): The vacuum provides the clean baseline environment necessary to introduce reactive gases with precision, giving you absolute control over the final film's properties.

Ultimately, the high vacuum in PVD is the fundamental enabler of the control, purity, and quality that defines modern thin-film deposition.

Summary Table:

| Vacuum Function | Benefit for PVD Coating |

|---|---|

| Creates a Clear Path | Increases mean free path for direct line-of-sight deposition |

| Prevents Contamination | Eliminates reactions with air, ensuring chemical purity |

| Enables Process Control | Allows precise introduction of reactive gases for compound films |

| Supports Plasma | Provides the low-pressure environment needed for stable plasma generation |

Achieve Superior Thin-Film Quality with KINTEK's Expertise

Do you require high-purity, durable coatings for your laboratory components or research applications? The controlled environment of a PVD system is critical to your success. KINTEK specializes in providing high-quality lab equipment and consumables tailored to meet the demanding needs of modern laboratories.

We can help you select the right PVD solutions to ensure your coatings are pure, dense, and perform to specification. Contact our experts today to discuss how our equipment can enhance your deposition processes and deliver reliable, high-performance results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications