Pouring molten metal at a temperature above its melting point is a critical, non-negotiable step in casting. This practice, known as applying superheat, is essential to compensate for the inevitable heat loss that occurs the moment the metal leaves the furnace. Without this thermal "buffer," the metal would begin to solidify prematurely, failing to completely fill the mold and resulting in a defective part.

The core challenge in metal casting is a race against time and temperature. The added heat above the melting point—the superheat—is the essential insurance that guarantees the liquid metal has enough thermal energy to travel through the ladle and completely fill the mold cavity before it begins to freeze.

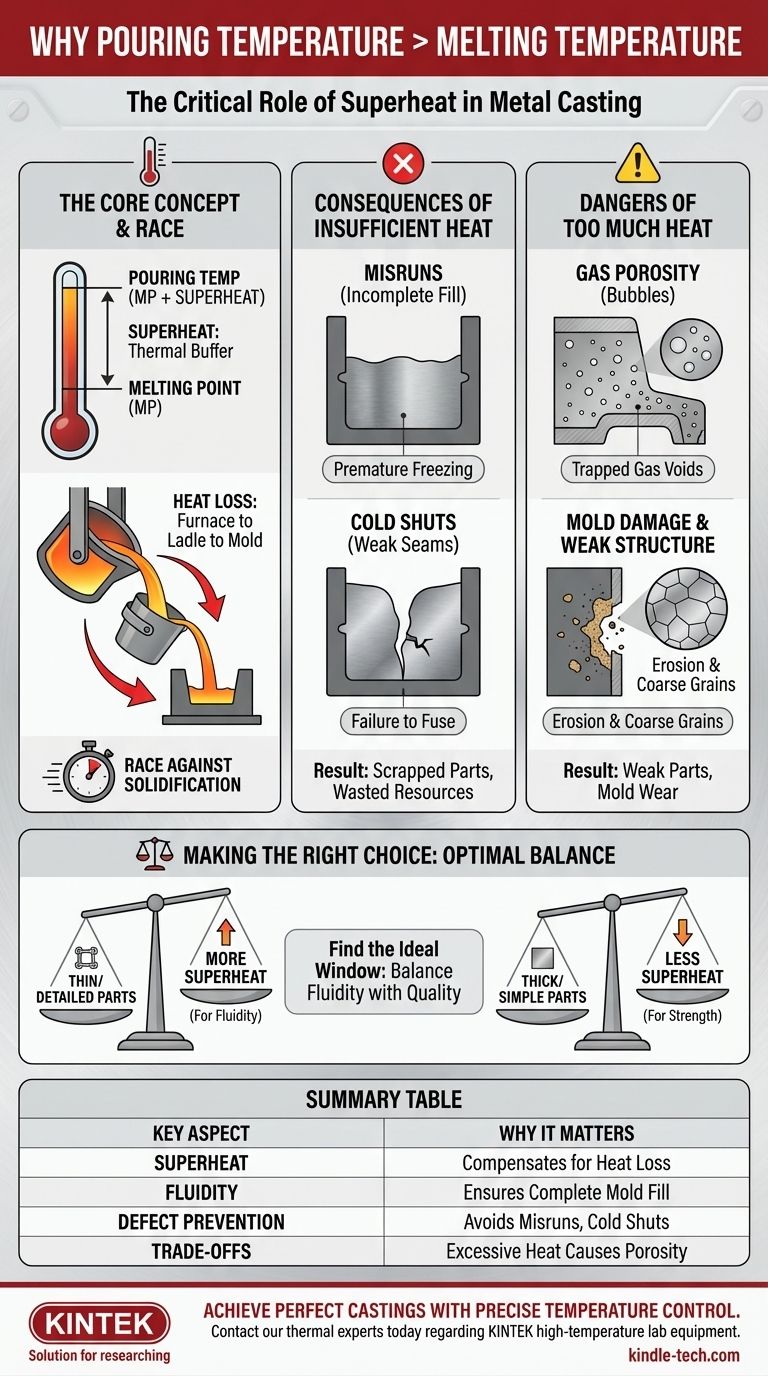

The Race Against Solidification: Why Superheat is Essential

Pouring metal precisely at its melting temperature is a theoretical ideal that fails in practice. The journey from furnace to mold is fraught with opportunities for the molten metal to lose critical thermal energy.

Compensating for Inevitable Heat Loss

From the moment it's tapped from the furnace, the molten metal begins cooling. Heat is lost to the transfer ladle, to the surrounding atmosphere, and most significantly, to the comparatively cold material of the mold itself. The superheat provides the necessary extra energy to absorb these losses and remain fully liquid.

Ensuring Complete Mold Filling (Fluidity)

Temperature is directly related to the fluidity (the inverse of viscosity) of molten metal. A higher degree of superheat makes the metal flow more like water than molasses. This improved fluidity is crucial for filling thin sections and capturing intricate details within the mold cavity.

Preventing Premature Freezing

If the metal's temperature drops to its melting point while it's still flowing, solidification begins immediately. This premature freezing is the root cause of several critical casting defects that render a part unusable.

The Consequences of Insufficient Temperature

Failing to apply enough superheat is not a minor process error; it directly leads to failed castings that must be remelted or scrapped, wasting time, energy, and money.

Misruns and Incomplete Castings

A misrun is the most straightforward defect. The metal loses too much heat, solidifies before the mold is full, and creates an incomplete part. This is a common result of pouring at too low a temperature.

Cold Shuts and Weak Seams

A cold shut occurs when two fronts of molten metal meet within the mold but are too cool to fuse together properly. This creates a crack-like discontinuity, or seam, in the final part, which represents a critical structural failure point.

Poor Surface Finish and Detail

Sluggish, barely-molten metal lacks the energy to press firmly against the mold walls. This results in rounded edges where sharp corners are intended and a failure to replicate fine surface textures or details from the mold pattern.

Understanding the Trade-offs: The Dangers of Too Much Heat

While superheat is necessary, excessive heat creates a different set of problems. The goal is to find the optimal temperature, not simply the highest one possible.

Increased Gas Porosity

Molten metals absorb ambient gases, like hydrogen and oxygen. The hotter the metal, the more gas it can hold in solution. As the metal cools and solidifies in the mold, this gas is forced out of solution, forming tiny bubbles that get trapped as gas porosity (voids), weakening the final casting.

Mold Damage and Reaction

Excessively high temperatures can damage the mold itself. In sand casting, it can cause the binder to break down or the metal to fuse with the sand, resulting in a poor surface finish. It can also accelerate erosion of the mold and runner system as the hot metal flows through.

Degraded Mechanical Properties

Pouring too hot significantly lengthens the solidification time. This slow cooling promotes the growth of large, coarse grains in the metal's microstructure, which typically reduces the part's final strength, ductility, and toughness.

Making the Right Choice for Your Process

The ideal pouring temperature is not a single value but a carefully calculated parameter based on the specific casting conditions. It is a balance between ensuring fluidity and avoiding the defects caused by excessive heat.

- If your primary focus is casting highly detailed, thin-walled parts: You will need a higher degree of superheat to ensure the metal's fluidity allows it to fill every intricate cavity before solidifying.

- If your primary focus is maximizing the strength of a simple, thick part: Use a pouring temperature just high enough to avoid misruns and cold shuts, as this will promote faster solidification and a stronger, finer-grained microstructure.

- If your primary focus is process stability and cost-efficiency: The goal is to identify the optimal pouring temperature window that consistently produces sound castings without wasting energy or causing excessive wear on equipment.

Ultimately, controlling the pouring temperature is one of the most powerful tools for guaranteeing the quality and integrity of the final cast component.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Superheat | Compensates for heat loss during transfer and pouring. |

| Fluidity | Ensures metal fills the entire mold, especially thin sections. |

| Defect Prevention | Avoids misruns, cold shuts, and poor surface finish. |

| Trade-offs | Excessive heat can cause gas porosity and weaker parts. |

Achieve Perfect Castings with Precise Temperature Control

Struggling with casting defects or inconsistent results? The precise thermal management of your molten metal is critical. KINTEK specializes in high-temperature lab equipment, including furnaces and temperature control systems, to help you achieve the perfect pouring temperature for your specific alloy and mold design.

Our solutions empower foundries and R&D labs to:

- Eliminate Defects: Ensure complete mold filling and strong, sound castings.

- Optimize Processes: Find the ideal temperature window for your part geometry and material.

- Improve Efficiency: Reduce scrap rates and save on material and energy costs.

Ready to perfect your casting process? Contact our thermal experts today to discuss how KINTEK's lab equipment can bring reliability and quality to your operation.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

People Also Ask

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What are the advantages and disadvantages of rotary furnace? Maximize Uniformity & Efficiency in Thermal Processing

- What are the advantages of a rotary furnace? Achieve Superior Homogeneity & Efficiency for Powders & Granules

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment