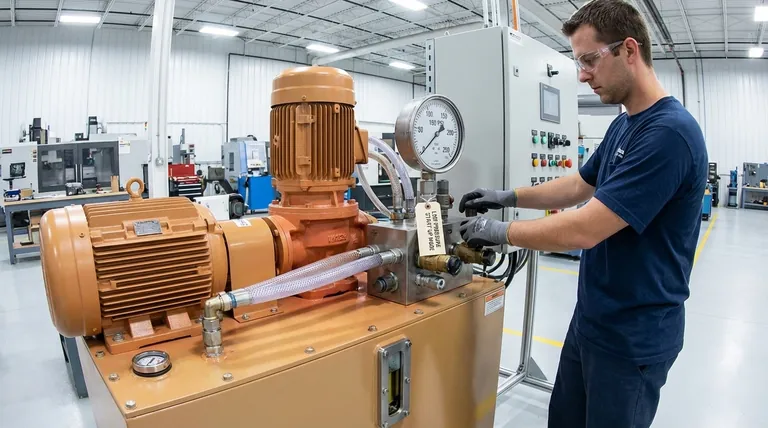

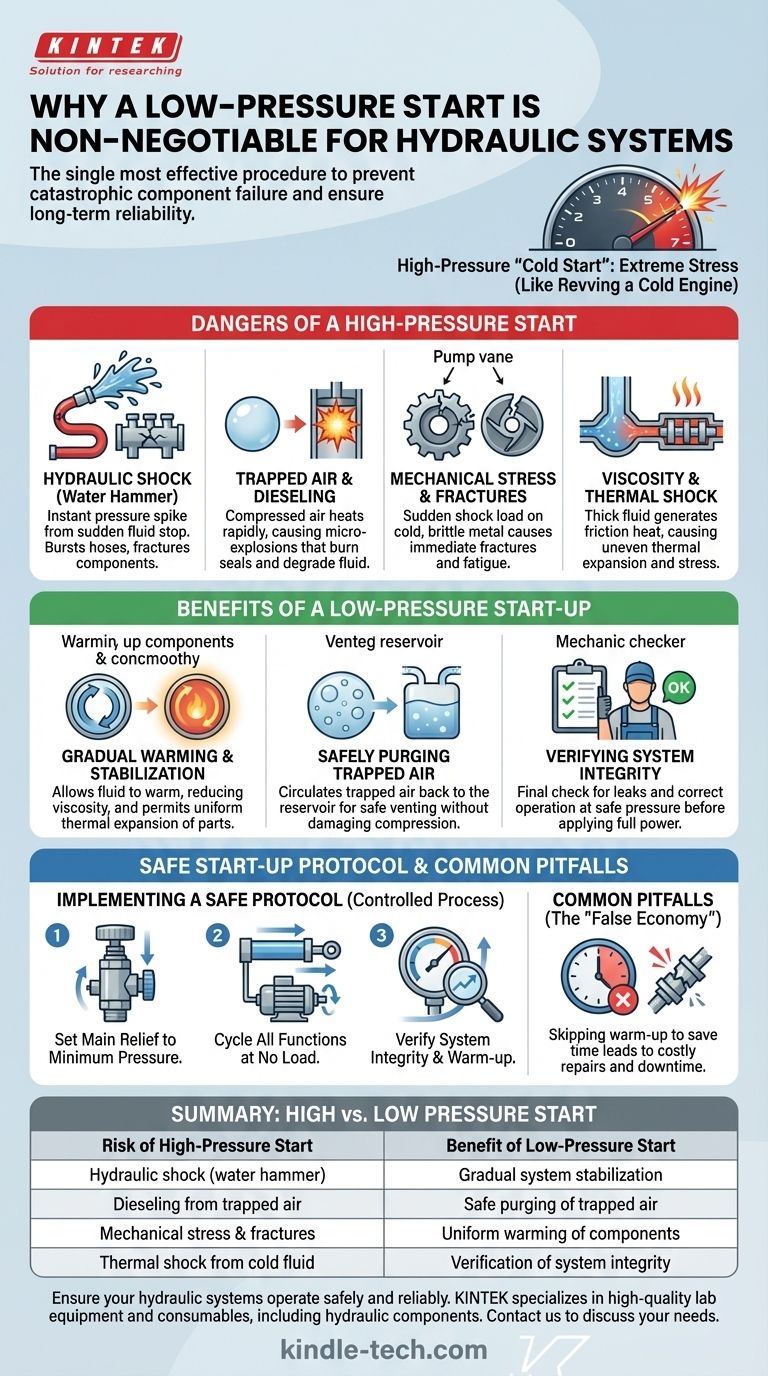

Starting a hydraulic system at low pressure is a non-negotiable safety and maintenance protocol. It is the single most effective procedure for preventing catastrophic component failure, hydraulic shock, and uncontrolled machine movement. By gradually introducing pressure, you allow the system to stabilize, purge trapped air, and verify its integrity before subjecting it to the immense forces of full operational power.

A high-pressure "cold start" is the hydraulic equivalent of revving a cold engine to its redline—it introduces extreme, unnecessary stress that can cause immediate, violent failure. A low-pressure start is a controlled sequence that allows the system's fluid, seals, and mechanical components to stabilize safely before work begins.

The Dangers of a High-Pressure Start

Ignoring a low-pressure start-up exposes the system to several immediate and severe risks. The sudden release of high-pressure fluid into a static system creates a chaotic and violent environment.

Hydraulic Shock (Water Hammer)

When high-pressure fluid is instantly introduced, it accelerates rapidly until it hits a restriction, a closed valve, or the end of a cylinder. This abrupt stop converts the fluid's kinetic energy into a massive pressure spike.

This phenomenon, known as hydraulic shock, can generate pressures several times higher than the system's maximum rating, potentially bursting hoses, cracking manifolds, or fracturing component housings.

The Problem of Trapped Air

Air pockets are almost always present in a system that has been shut down. Unlike hydraulic fluid, which is nearly incompressible, air is highly compressible.

When high-pressure fluid slams into a pocket of trapped air, the air is compressed so rapidly that its temperature skyrockets, often exceeding the ignition point of the hydraulic fluid. This causes a micro-explosion known as dieseling, which burns seals and degrades the fluid. The subsequent re-expansion of the gas and fluid creates a secondary shockwave, further stressing components.

Mechanical Stress on Components

Metal components, especially when cold, are more brittle. A sudden application of thousands of PSI is a massive physical blow.

This shock loading can cause immediate fractures in pump vanes, gear teeth, or valve spools. Even if it doesn't cause an immediate break, it induces micro-fractures and metal fatigue, drastically shortening the component's operational lifespan.

Viscosity and Thermal Shock

Cold hydraulic fluid has a high viscosity, meaning it is thick and resistant to flow. Forcing this thick fluid through the system's small orifices and passages at high pressure generates extreme friction and localized heat.

This creates thermal shock, where parts of a component heat up much faster than others, causing uneven expansion and stress. It also prematurely breaks down the fluid's additives, reducing its lubricating properties.

The Benefits of a Low-Pressure Start-Up

A proper start-up sequence is a deliberate process of bringing the system online gently. It transforms a moment of high risk into a valuable diagnostic opportunity.

Gradual Warming and Stabilization

A low-pressure start, typically achieved by setting the main system relief valve to its minimum setting, allows fluid to circulate gently.

This gradual flow allows the fluid to warm up slowly, reducing its viscosity to the correct operating level. It also allows all metal components to heat up and expand uniformly, eliminating internal stresses.

Safely Purging Trapped Air

Low-pressure circulation gives trapped air a chance to be carried along with the fluid back to the reservoir, where it can be safely vented.

Because the pressure is low, any remaining air pockets that get compressed do not generate the damaging heat and force seen in a high-pressure start. This process is essential for smooth, predictable actuator movement.

Verifying System Integrity

A low-pressure start is your final opportunity to ensure the system is safe and functional before applying full power.

During this phase, you can check for external leaks, listen for abnormal noises like pump cavitation (a sign of air or starvation), and confirm that actuators respond correctly to control inputs. Finding a problem at 200 PSI is an inconvenience; finding the same problem at 3,000 PSI can be a disaster.

Understanding the Common Pitfalls

Even with good intentions, operators can make critical mistakes that negate the benefits of a proper start-up.

The "False Economy" of Speed

The most common pitfall is viewing the warm-up procedure as a waste of time. The desire to start work immediately leads operators to skip this crucial step.

This is a false economy. The few minutes "saved" are paid for with weeks of downtime and thousands of dollars in repairs when a component inevitably fails from the repeated stress.

Misunderstanding the "Low Pressure" Setting

"Low pressure" does not mean zero. It refers to the minimum pressure required to circulate fluid throughout the entire circuit.

This is usually achieved by backing out the adjustment on the main system pressure relief valve. The goal is to allow flow and function without building force. Starting the pump against a dead-end (like a closed-center valve with no relief) will still cause an instantaneous pressure spike to the maximum setting.

Neglecting to Cycle the System

Simply starting the pump at low pressure is not enough. The system must be cycled.

This means operating all functions—extending and retracting all cylinders, turning all hydraulic motors—at no load. This is the only way to ensure warm fluid reaches every part of the circuit and to push trapped air out of every corner.

Implementing a Safe Start-Up Protocol

A standardized start-up procedure is a cornerstone of any professional maintenance program. The focus of the procedure shifts slightly depending on your top priority.

- If your primary focus is equipment longevity: Always begin with the pressure relief valve at its minimum setting to minimize the mechanical and thermal stress that shortens component life.

- If your primary focus is operator safety: Use the low-pressure start to verify system integrity, checking for leaks and correct operation before introducing high-energy force that can cause violent failures.

- If your primary focus is system reliability: Cycle all functions at low pressure and no load to effectively purge trapped air, which is a primary cause of erratic behavior and internal component damage.

By treating every start-up as a controlled and deliberate process, you transform a routine task into a powerful tool for ensuring safety, reliability, and long-term performance.

Summary Table:

| Risk of High-Pressure Start | Benefit of Low-Pressure Start |

|---|---|

| Hydraulic shock (water hammer) | Gradual system stabilization |

| Dieseling from trapped air | Safe purging of trapped air |

| Mechanical stress & fractures | Uniform warming of components |

| Thermal shock from cold fluid | Verification of system integrity |

Ensure your hydraulic systems operate safely and reliably. Proper start-up procedures are just one part of a comprehensive maintenance strategy. KINTEK specializes in providing high-quality lab equipment and consumables, including hydraulic system components and testing apparatus, to help laboratories maintain peak performance and safety. Contact us today to discuss your specific needs and let our experts help you build a safer, more efficient operation. Reach out via our contact form to get started!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What are the advantages of using KBr in IR spectroscopy sample preparation? Achieve Clean, Accurate Spectra

- How do you convert hydraulic pressure to force? Master the Core Formula for Maximum Power

- How do I choose a hydraulic press machine? A Guide to Matching Tonnage, Size & Control

- Why is a high-pressure hydraulic press used for solid-state batteries? Achieve Optimal Li-Anode & Sulfide Integration

- What is the difference between fused beads and pressed pellets? Choose the Right XRF Sample Prep Method

- What are the methods of cooling the hydraulic system? Choose the Right Cooler for Reliability & Longevity

- What is the size range of pellets? From 1mm to 25mm, Find the Perfect Fit for Your Application

- What happens if hydraulic pressure is too high? Prevent Catastrophic System Failure and Downtime