You’re looking at the lab report again. The chemical composition of your latest batch is off-spec. It’s the third time this month. The production line is stalled, a valuable client is waiting, and thousands of dollars in high-grade alloys are now essentially scrap. You’ve double-checked the raw materials, calibrated the temperature sensors, and tweaked the cycle times. Yet, the results are still unpredictable. It feels like you’re battling a ghost in the machine.

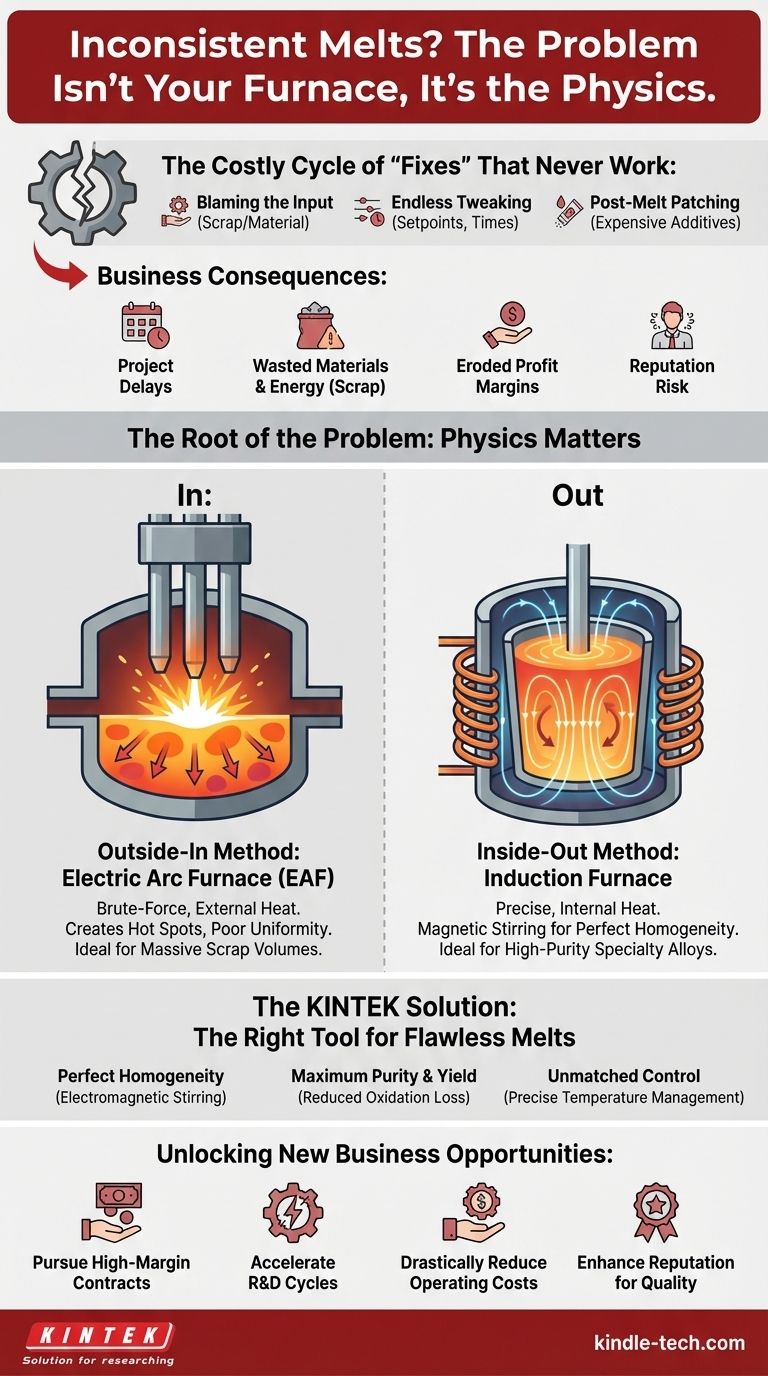

The Costly Cycle of "Fixes" That Never Work

This scenario is frustratingly common in foundries and labs focused on high-quality metals. When faced with inconsistent melts, contamination, or poor alloy homogeneity, the typical response is a frantic checklist of adjustments:

- Blaming the Input: "It must be a bad batch of scrap or raw material."

- Endless Tweaking: Constantly adjusting temperature setpoints, hold times, and power levels, hoping to stumble upon a 'magic number'.

- Post-Melt Patching: Attempting to correct the molten bath with expensive additives, a process that is both costly and unreliable.

These efforts, while well-intentioned, are often a dead end. They treat the symptoms, not the disease. The business consequences are severe and tangible: project delays stretch into months, R&D cycles are crippled by unreliable data, and profit margins are eroded by wasted energy and materials. Most critically, your reputation for quality and reliability is put at risk with every inconsistent batch that leaves the door.

The Root of the Problem: Heating from the Outside-In vs. Inside-Out

The reason these fixes fail is that the problem isn't in your settings or your inputs. It's in the fundamental physics of how your furnace generates heat.

Most people in the industry talk about "Electric Furnaces" as a single category. However, the critical distinction isn't between "electric" and something else—it's between the two dominant types of electric furnaces: the Electric Arc Furnace (EAF) and the Induction Furnace. They operate on completely different principles.

The "Outside-In" Method: The Electric Arc Furnace (EAF)

An EAF works like a controlled lightning strike. It uses massive graphite electrodes to create an incredibly hot electric arc that blasts the surface of the metal. Heat is generated outside the material and then transfers inward.

This is a powerful, brute-force method, excellent for melting enormous quantities of scrap steel quickly. However, it's inherently less controlled. It creates intense hot spots, makes achieving a uniform temperature difficult, and can introduce impurities from the electrodes or atmosphere.

The "Inside-Out" Method: The Induction Furnace

An induction furnace works like a high-powered, non-contact microwave for metal. It uses a magnetic field to generate electrical currents directly inside the metal itself. The metal's own resistance to these currents creates heat from within.

This "inside-out" heating is incredibly precise, fast, and uniform. Furthermore, the magnetic field naturally and gently stirs the molten bath, ensuring all the elements are perfectly mixed.

This is the "aha" moment: If you are trying to achieve perfect alloy homogeneity using an "outside-in" heating tool, you are constantly fighting its fundamental nature. No amount of tweaking can fully compensate for a heating method that isn't designed for precision.

The Right Tool for a Flawless Melt: Why Physics Matters

To solve a problem at its root, you need a tool that is fundamentally aligned with your goal.

- If your goal is brute-force melting of massive scrap volumes, the external power of an EAF is the right tool.

- If your goal is producing high-purity, perfectly homogeneous specialty alloys, you need the precise, internal heating of an induction furnace.

This is not a matter of one furnace being "better" than the other; it's about choosing the right physical principle for the job. An induction furnace isn't just a container that gets hot—it is a precision instrument engineered to control metallurgical properties at a molecular level.

Where KINTEK's Solutions Fit In

At KINTEK, we built our thermal processing solutions based on a deep understanding of these principles. Our induction furnaces are not just an alternative; they are the purpose-built answer for labs and producers who cannot compromise on quality.

- For Perfect Homogeneity: The inherent electromagnetic stirring in our furnaces guarantees a uniform mixture, eliminating the inconsistencies that plague EAFs.

- For Maximum Purity & Yield: The contained, internal heating process dramatically reduces the loss of expensive alloying elements to oxidation, saving you money on every single melt.

- For Unmatched Control: By generating heat directly within the material, our systems provide the precise temperature control needed to meet the strictest specifications for aerospace, medical, or other high-performance applications.

Our equipment is designed to solve the problem of inconsistency at its source, making quality a predictable outcome, not a game of chance.

Beyond Fixing Problems: Unlocking New Business Opportunities

Once you stop fighting your equipment and start using the right tool, you do more than just solve an old problem. You unlock entirely new potentials for your business.

With the reliable precision of a KINTEK induction furnace, you can now:

- Confidently pursue high-margin contracts in demanding industries like aerospace, medical, and electronics.

- Accelerate R&D cycles by producing consistent, repeatable test batches every time.

- Drastically reduce operating costs through higher energy efficiency and near-zero loss of valuable alloys.

- Enhance your reputation as a supplier of choice for top-tier, quality-critical components.

Solving your melt inconsistency issue isn't just about fixing a technical glitch; it's about elevating your operational capabilities and competitive standing in the market.

This core principle—identifying the root physical cause of a problem and applying the correctly engineered tool—is at the heart of everything we do at KINTEK. Our expertise goes beyond just selling equipment; we partner with you to solve your most fundamental processing challenges. If you're ready to move from fixing recurring problems to unlocking new potential, our team is here to help. Let's discuss your specific application and find the right solution for your goals. Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

Related Articles

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- Exploring Tungsten Vacuum Furnaces: Operation, Applications, and Advantages

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.