The Weight of Nothing

We tend to think of engineering in terms of addition: adding steel for strength, adding circuits for logic, adding fuel for power.

But in materials science, the most critical step is often subtraction.

In a vacuum furnace, pressure is not merely a dial to be watched. It is a precise architectural variable. It is the art of removing the atmosphere—specifically the chaotic, reactive nature of oxygen—to create a sanctuary where chemistry behaves exactly as we intend.

If you leave the "door open" to the atmosphere, even microscopically, the physics change. Materials oxidize. Bonds fail. The process collapses.

Here is how the best engineers navigate the invisible landscape of vacuum pressure.

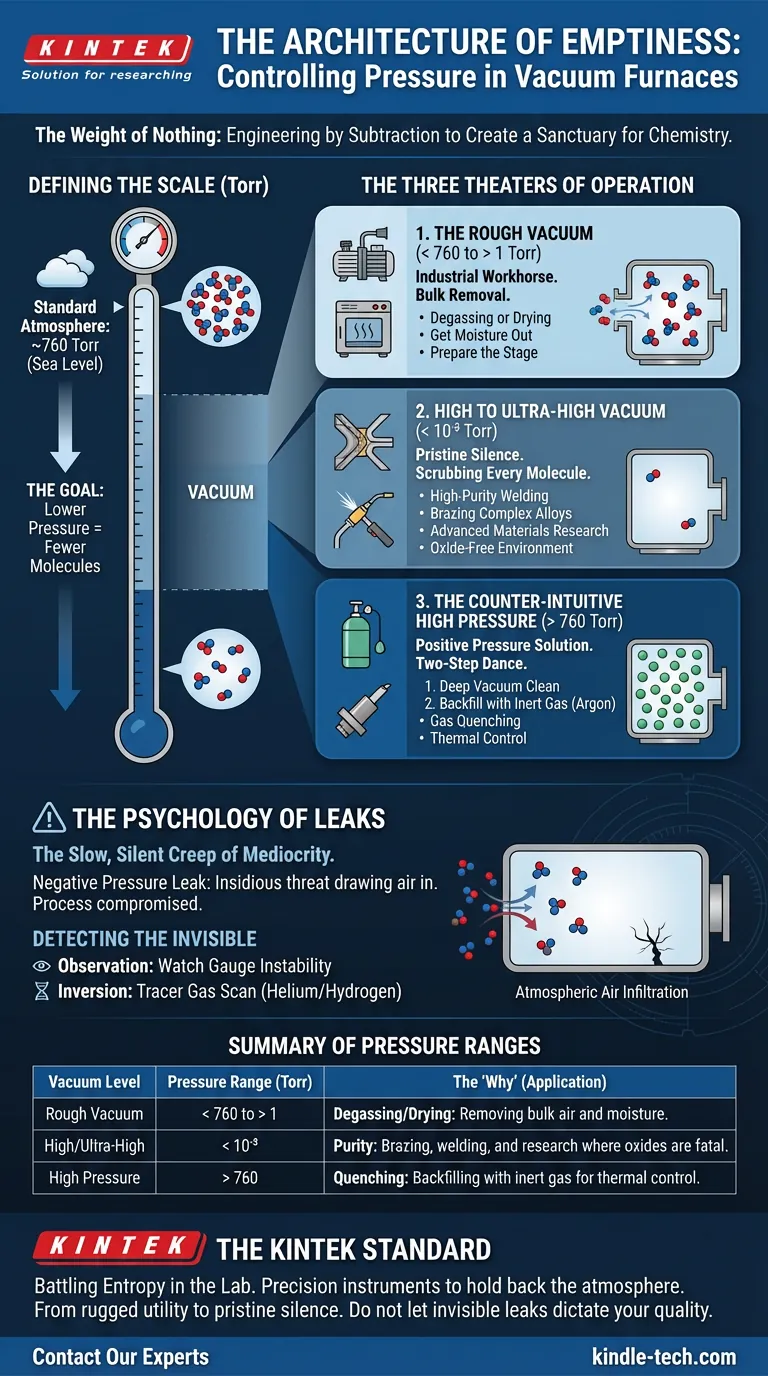

Defining the Scale

To control an environment, you must first measure it.

In the context of a vacuum furnace, pressure is simply the force exerted by the air molecules remaining inside the chamber. We measure this in Torr.

- Standard Atmosphere: ~760 Torr (Sea level).

- The Goal: Anything lower than 760 Torr is technically a vacuum.

The "harder" the vacuum, the lower the Torr value, and the fewer molecules remain to interfere with your work.

The Three Theaters of Operation

The pressure level you select dictates the reality inside the furnace. It is not a linear progression of "better," but a specific choice based on the sensitivity of your material.

1. The Rough Vacuum (< 760 to > 1 Torr)

This is the industrial workhorse range. It is not about perfect purity; it is about bulk removal.

We use this for degassing or drying. The goal here is mechanical: get the moisture out, remove the bulk air, and prepare the stage. It is sufficient, cost-effective, and robust.

2. High to Ultra-High Vacuum (< 10⁻⁸ Torr)

This is where the physics gets interesting.

In this range, we are scrubbing the environment of almost every rogue molecule. This is reserved for the most sensitive operations:

- High-purity welding.

- Brazing complex alloys.

- Advanced materials research.

At 10⁻⁸ Torr, you are ensuring that when metal flows, it meets only metal—not oxides, not contaminants.

3. The Counter-Intuitive High Pressure (> 760 Torr)

Sometimes, the solution to a vacuum problem is positive pressure.

Advanced furnaces operate in a two-step dance:

- Pull a deep vacuum to clean the environment.

- Backfill with an inert gas (like Argon) to levels above atmospheric pressure.

This is critical for gas quenching or specific bonding cycles where heat transfer needs to be accelerated or suppressed instantly.

The Psychology of Leaks

The greatest threat to a vacuum furnace is rarely a catastrophic explosion. It is the slow, silent creep of mediocrity caused by a leak.

A negative pressure leak is insidious. It draws atmospheric air into the chamber through a faulty seal or a microscopic crack. Because the furnace is often still "working," operators might ignore the drift.

But chemistry does not ignore it.

The Cost of Drift

If a vacuum pump cannot hold its target, the process is compromised. In sensitive applications—like dental porcelain firing or aerospace brazing—a deviation of a few Torr changes the structural integrity of the final product.

The product looks fine. But inside, it is weak.

Detecting the Invisible

You cannot fix what you cannot see. Troubleshooting requires shifting perspective:

- Observation: Watch the gauge. Instability is the first red flag.

- Inversion: To find a leak, technicians often fill the chamber with a tracer gas (creating positive pressure) and scan the exterior with a helium or hydrogen detector.

Summary of Pressure Ranges

| Vacuum Level | Pressure Range (Torr) | The "Why" (Application) |

|---|---|---|

| Rough Vacuum | < 760 to > 1 | Degassing/Drying: Removing bulk air and moisture. |

| High/Ultra-High | < 10⁻⁸ | Purity: Brazing, welding, and research where oxides are fatal. |

| High Pressure | > 760 | Quenching: Backfilling with inert gas for thermal control. |

The KINTEK Standard

In the laboratory, you are battling entropy. Every variable you fail to control introduces chaos into your results.

At KINTEK, we understand that a vacuum furnace is not just a hot box—it is a precision instrument designed to hold back the weight of the atmosphere. Whether you need the rugged utility of a rough vacuum for drying or the pristine silence of an ultra-high vacuum for advanced R&D, our equipment is engineered to hold the line.

Do not let invisible leaks dictate your quality standards.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Mesh belt controlled atmosphere furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

Related Articles

- How Controlled Atmosphere Furnaces Improve Quality and Consistency in Heat Treatment

- Hydrogen Atmosphere Furnaces: Applications, Safety, and Maintenance

- The Benefits of Controlled Atmosphere Furnaces for Sintering and Annealing Processes

- Exploring the Using a Chamber Furnace for Industrial and Laboratory Applications

- Atmosphere Furnaces: Comprehensive Guide to Controlled Heat Treatment