You’ve seen it before. A batch of meticulously designed, machined, and cleaned components goes into the brazing furnace. The thermal profile runs perfectly. Hours later, the parts come out, and the inspection begins. Instead of strong, clean joints, you find voids, incomplete flow, or worse, a distorted assembly. The entire batch is now expensive scrap, and your project timeline just took another hit.

Why does this keep happening? It's a deeply frustrating problem that plagues even the most experienced engineering teams.

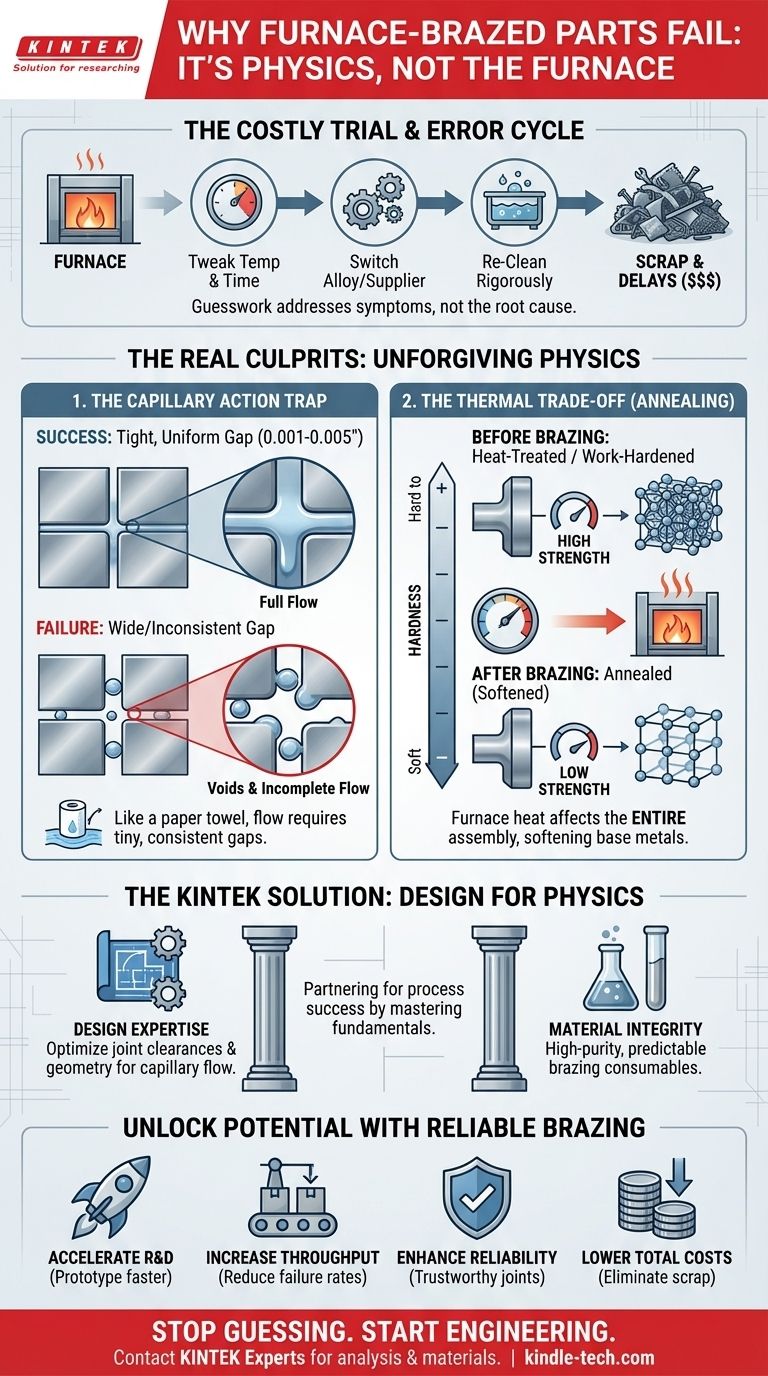

The Costly Cycle of Trial and Error

When furnace brazing fails, the troubleshooting scramble begins. It’s a familiar dance:

- “Let’s tweak the furnace temperature.” You adjust the ramp-up speed or the time at peak temperature, hoping a slight change will fix the flow.

- “Maybe it’s the braze alloy.” You switch to a different filler metal or a different supplier, suspecting an issue with the material itself.

- “The parts must not be clean enough.” You implement an even more rigorous, time-consuming cleaning protocol before the next run.

Sometimes, one of these changes seems to work, giving you a single successful batch. But soon enough, the inconsistency returns. This cycle of guesswork isn't just frustrating; it has severe business consequences. Each failed batch wastes thousands of dollars in high-precision machined parts, specialized materials, and energy costs. Project deadlines are missed, product launches are delayed, and your team's confidence in a critical manufacturing process is eroded.

The core problem is that these "solutions" are merely addressing the symptoms. The real disease lies deeper, rooted in the fundamental physics of the process.

The Real Culprit: Two Unforgiving Laws of Physics

Furnace brazing doesn't fail because the furnace is faulty or the alloy is bad. It fails when the design of the assembly ignores two non-negotiable physical principles. It's a process that offers perfection but forgives nothing.

The Capillary Action Trap: Why "Close Enough" Fails

Furnace brazing depends entirely on a phenomenon called capillary action to pull the molten filler metal into the joint. Think of how a paper towel instantly wicks water up its fibers. That only works because the gaps between the fibers are incredibly small and consistent.

The same rule applies to your parts.

- The Truth: For capillary action to work, the gap (or clearance) between your two parts must be extremely tight and uniform—typically between 0.001 to 0.005 inches (0.025 to 0.127 mm).

- The Failure: If the gap is too wide, inconsistent, or tapered, capillary force breaks down. The molten alloy will simply sit there or flow partially, leaving voids and creating a weak, unreliable joint.

Tweaking the furnace temperature cannot force liquid metal to defy physics and jump across a wide gap. The problem isn't the heat; it's the geometry.

The Thermal Trade-Off: The Heat That Gives Also Takes Away

A furnace, by its very nature, heats the entire assembly to the brazing temperature, not just the joint area. This has an enormous, unavoidable consequence on your base materials.

- The Truth: If your parts were heat-treated or work-hardened to give them specific strength and hardness, the brazing cycle will almost certainly anneal them. Annealing is a process that softens metal, effectively erasing the benefits of prior hardening treatments.

- The Failure: You might get a perfect braze joint, but the components themselves are now too soft to meet the product’s performance requirements. The part fails in the field not at the joint, but because the base material has lost its strength.

This isn't a defect in the process; it's an inherent trade-off. You must design your part knowing this softening will occur.

A Solution Designed for Physics, Not Guesswork

Once you understand that successful brazing is determined before the parts ever enter the furnace, the path forward becomes clear. You must shift your focus from tweaking the process to perfecting the design and preparation.

To do this effectively, you need a method that respects these physical laws. This requires two key elements:

- Design Expertise: The ability to design joints with precise, consistent clearances and features that hold the filler metal correctly.

- Material Integrity: Access to high-purity, perfectly consistent brazing consumables that behave predictably every single time.

This is precisely why KINTEK is more than just a supplier of lab consumables; we are a partner in process success. Our value is built on helping you master the fundamentals. We provide not just the high-purity braze alloys, pastes, and preforms that ensure predictable capillary flow, but also the expert guidance to help you design your components for successful, repeatable brazing from the start. Our products are not just materials; they are instruments of certainty, engineered to work with the laws of physics, not against them.

Beyond Troubleshooting: What Reliable Brazing Unlocks

When you stop fighting inconsistent results, you can finally leverage furnace brazing for its intended purpose: creating superior products at scale. Moving from a reactive to a proactive approach unlocks significant new potential for your business.

Instead of dedicating resources to inspecting and reworking failed parts, your team can:

- Accelerate R&D: Confidently prototype complex, multi-component assemblies that were previously too risky.

- Increase Production Throughput: Drastically reduce failure rates, turning wasted capacity into shippable products.

- Enhance Product Reliability: Deliver parts with consistently strong, hermetically sealed joints that build trust with your customers.

- Lower Total Costs: Eliminate the immense expense of scrapped materials, wasted labor, and production delays.

In short, when you solve the brazing problem at its root, you transform a source of chronic frustration into a competitive advantage.

Stop letting a misunderstanding of physics dictate your production schedule and budget. It's time to move from fighting technical fires to achieving your strategic goals. If you're ready to achieve consistent, reliable brazing results for your critical projects, our team is here to help you analyze your design and select the ideal materials for the job. Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

Related Articles

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- The Art of the Void: When Precision Matters More Than Power

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Exploring Tungsten Vacuum Furnaces: Operation, Applications, and Advantages