Have you ever invested in high-purity graphite for a critical high-temperature process, only to watch it degrade and fail at temperatures far below its advertised limit? One moment it's a precision-machined crucible or heating element; the next, it's flaking away, contaminating your sample, and bringing your experiment to a screeching halt.

You're left staring at a compromised result, a wasted budget, and a frustrating question: "This material is supposed to withstand over 3,600°C. Why is it failing at 800°C?"

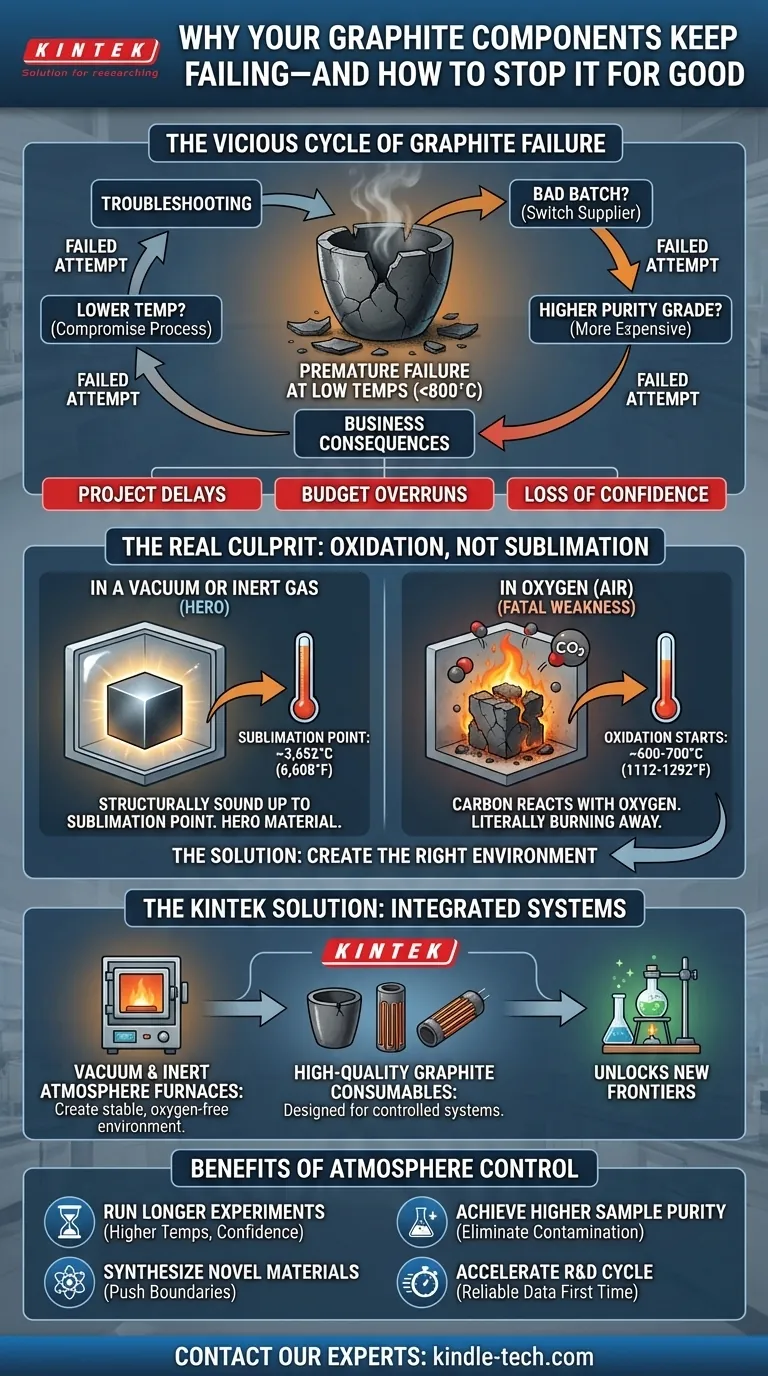

The Vicious Cycle: Chasing Ghosts and Hidden Costs

If this scenario sounds familiar, you're not alone. This is a common and costly problem in labs and industrial settings worldwide. When faced with premature graphite failure, most teams enter a familiar cycle of troubleshooting:

- "Maybe it was a bad batch?" You switch suppliers, hoping for better quality, but the problem persists.

- "Perhaps we need a higher purity grade?" You invest in more expensive, ultra-high-purity graphite, only to watch it suffer the same fate.

- "Let's just lower the operating temperature." You compromise your process parameters, limiting your research and potentially invalidating your entire experiment's goal.

Each failed attempt does more than just consume another graphite component. It triggers a cascade of negative business consequences: project delays that push back timelines, budget overruns from replacing expensive parts and re-running tests, and, most critically, a loss of confidence in your data and processes.

The reason these "solutions" fail is that they are all based on a fundamental misunderstanding of how graphite behaves in the real world.

The Real Culprit: It’s Not Sublimation, It’s Oxidation

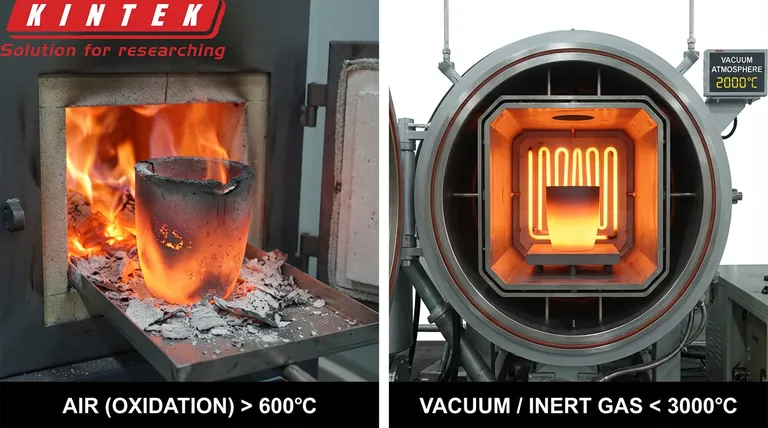

The incredible temperature resistance you see on a graphite spec sheet—often cited as 3,652°C (6,608°F)—refers to its sublimation point. This is the temperature at which it turns directly from a solid to a gas. However, this remarkable feat is only possible under one, very specific condition: an oxygen-free environment, such as a vacuum or an inert gas atmosphere (like argon).

For most labs operating in open air, a completely different and far more destructive process takes over at a much lower temperature: oxidation.

The Two Fates of Heated Graphite

Think of it as graphite having two completely different destinies, dictated entirely by its surroundings:

- In a Vacuum or Inert Gas: Here, graphite is a hero. It remains structurally sound up to its sublimation point, outperforming almost any other material.

- In the Presence of Oxygen (Air): Here, graphite has a fatal weakness. Starting around 600-700°C (1112-1292°F), the carbon atoms begin to react with oxygen, turning into carbon dioxide gas. The graphite isn't melting or sublimating; it is literally burning away.

This is why buying a "better" or "stronger" grade of graphite doesn't solve the problem. You aren't fighting a material weakness; you are fighting a chemical reaction. Without addressing the oxygen, any graphite component will inevitably degrade.

The Solution: Creating the Right Environment, Not Just Finding the Right Material

Once you understand that the environment is the true variable, the path forward becomes clear. To unlock graphite's legendary heat resistance, you must control its atmosphere.

The solution isn't to find a magical type of graphite that resists oxidation. It's to equip your lab with the tools designed to create the precise, oxygen-free conditions where graphite can perform as intended. This means moving beyond just buying a graphite consumable and instead investing in an integrated system.

This is precisely where KINTEK's expertise comes in. We don't just supply high-quality graphite components; we provide the complete ecosystem they need to thrive:

- Vacuum & Inert Atmosphere Furnaces: Our furnaces are engineered to create and maintain the stable, oxygen-free environment required to prevent oxidation, allowing you to safely reach the extreme temperatures your research demands.

- High-Quality Graphite Consumables: Our crucibles, heating elements, and fixtures are designed to work seamlessly within these controlled systems, ensuring predictable performance and longevity.

Our products are not just pieces of hardware; they are the embodiment of this core scientific principle. They are designed from the ground up to solve the oxidation problem, transforming graphite from a frustratingly fragile material into a reliable and powerful tool for innovation.

Beyond Troubleshooting: Unlocking New Frontiers in High-Temperature Work

What happens when you stop worrying about your equipment failing and can finally trust your process? You unlock a new level of possibility.

By controlling the atmosphere, you're not just fixing a nagging problem; you are fundamentally upgrading your lab's capabilities. You can now:

- Run longer experiments at higher temperatures with confidence and repeatability.

- Synthesize and test novel materials that were previously out of reach due to process limitations.

- Achieve higher sample purity by eliminating contamination from degrading components.

- Accelerate your R&D cycle by moving from short, risky tests to stable, long-duration processes that yield reliable data the first time.

Ultimately, mastering graphite's environment frees you to focus on your real work: pushing the boundaries of science and engineering.

This principle extends beyond graphite. Success in advanced materials and high-temperature processes often depends on having a complete, integrated system where every component works in harmony. If you're facing challenges with your applications or want to ensure your next project is built on a foundation of reliability, our team is here to help. Let's discuss your unique requirements and find the right solution. Contact Our Experts.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

Related Articles

- Beyond Temperature: Why Your Furnace Brazing Fails and How to Get It Right

- Optimizing Performance with Graphite Vacuum Furnaces: A Comprehensive Guide

- Inconsistent Melts? The Problem Isn't Your Furnace, It's the Physics.

- Unveiling Vacuum Graphite Furnaces: Performance, Applications, and Expert Insights

- How to Maintain Your Dental Ceramic Furnace