You pull a batch of newly brazed components from the furnace. They look perfect. But during quality control, the joint fails under a fraction of its expected load. Or perhaps you see the problem immediately: the delicate parts have warped, distorted, or slumped, rendering hours of work and expensive materials useless. It’s a frustratingly common scenario that leaves engineers and technicians wondering, "We followed the datasheet—what went wrong?"

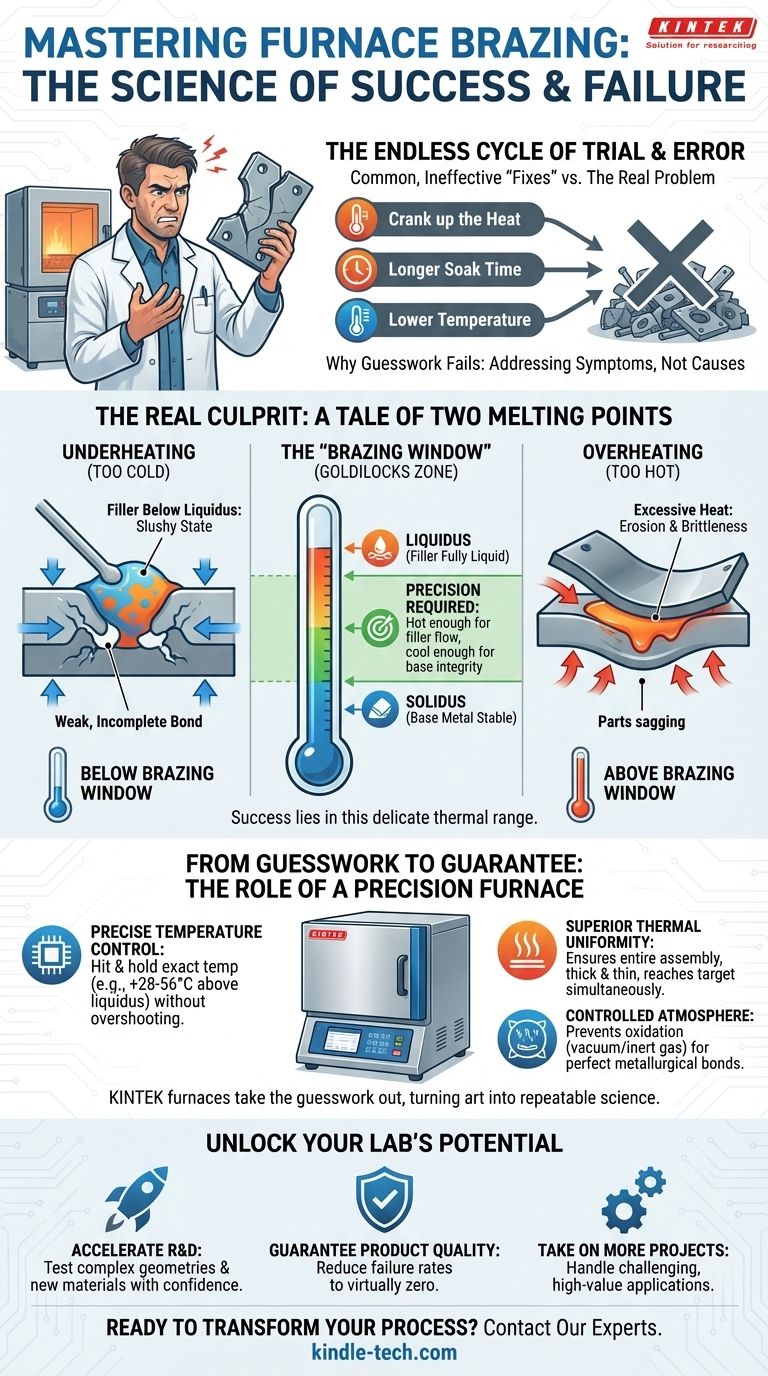

The Endless Cycle of Trial and Error

If this sounds familiar, you're not alone. Across countless labs and production floors, teams are caught in a loop of trying to solve inconsistent brazing results. The typical response is to start tweaking the process:

- "The filler didn't flow completely. Let's crank up the heat by another 50 degrees."

- "The parts warped last time. Let's lower the temperature to be safe."

- "Maybe we just need a longer soak time."

Each adjustment is a shot in the dark, and the results are often just as unpredictable. This isn't just a technical headache; it's a significant business problem. Every failed batch means scrapped high-value components, pushing project timelines back by weeks or even months. It erodes confidence in your manufacturing process and can ultimately lead to unreliable products and a damaged reputation.

The truth is, these common "fixes" are doomed to fail because they only address the symptoms. The real problem lies in a fundamental misunderstanding of what’s happening inside the furnace.

The Real Culprit: A Tale of Two Melting Points

Success in furnace brazing isn’t about hitting a single, magical temperature. It’s about precisely navigating a narrow thermal “safe zone” determined by the materials themselves. To understand this, we need to look at two critical temperatures—not just one.

Welcome to the "Brazing Window"

Every metal alloy has a unique melting range, defined by two points:

- Solidus: The temperature where the metal begins to melt. Think of it as the point ice turns into a slushy mix.

- Liquidus: The temperature where the metal becomes completely liquid. This is the point the slush turns into pure water.

For a strong joint, your filler metal must become fully liquid so it can flow like water and be pulled into the joint by capillary action. This means your furnace temperature must be above the filler metal's liquidus point.

At the same time, your base parts must remain solid and stable. This means the furnace temperature must stay below the base material's solidus point.

This delicate range—hot enough to melt the filler completely, but cool enough to protect the parts—is the "Brazing Window." It’s the Goldilocks zone of brazing: not too hot, not too cold.

Why "A Little Hotter" Is a Recipe for Disaster

The common "fixes" fail because they don't respect this window.

- Heating Too Low (Underheating): If you don't get above the filler's liquidus, it remains in a thick, "slushy" state. It can't flow properly, resulting in voids, incomplete joints, and a bond that is fundamentally weak and unreliable.

- Heating Too High (Overheating): Even if you're below the base metal's melting point, excessive heat is dangerous. It can cause the liquid filler to "dissolve" or erode the base metal, creating brittle compounds that dramatically reduce the joint's strength. At worst, it causes the parts to sag and distort, resulting in catastrophic failure.

The core problem is a lack of control. To consistently operate within the narrow Brazing Window, you can't rely on guesswork. You need a tool designed for precision.

From Guesswork to Guarantee: The Role of a Precision Furnace

To stay within the critical Brazing Window and achieve perfect joints every time, you need a system that can manage heat with absolute precision. This is where a purpose-built lab furnace moves from being a simple piece of equipment to an essential part of your quality control.

KINTEK's laboratory furnaces are not just "ovens." They are sophisticated thermal management systems, engineered based on a deep understanding of these material science principles. They are designed to be the ideal tool for this exact challenge.

How the Right Tool Solves the Root Problem

A high-performance furnace directly addresses the root causes of brazing failure:

- Precise Temperature Control: It allows you to program, hit, and hold the exact temperature required—typically 28-56°C (50-100°F) above the filler's liquidus—without the risk of overshooting. This eliminates the primary cause of overheating.

- Superior Thermal Uniformity: Advanced heating elements and insulation ensure the entire assembly, including both thick and thin sections, reaches the target temperature at the same time. This prevents one part of the joint from being "slushy" while another is fully liquid, guaranteeing a complete and uniform fill.

- Controlled Atmosphere: At high temperatures, oxygen is the enemy. It creates oxides on the metal surface that prevent the filler from bonding. KINTEK furnaces provide controlled atmospheres (like vacuum or inert gas) to protect the parts, ensuring the surfaces are perfectly clean for a strong, metallurgical bond.

In short, a precision furnace takes the guesswork out of the equation. It provides the control needed to navigate the Brazing Window with confidence, turning an unreliable art into a repeatable science.

Beyond Troubleshooting: What Perfect Brazing Unlocks for Your Lab

When you are no longer fighting with inconsistent results, you can redirect your energy from fixing problems to creating value. Mastering your brazing process with the right equipment unlocks new potential for your entire operation.

You can now confidently accelerate R&D, testing complex geometries and new material combinations without your equipment being the limiting factor. You can guarantee product quality, reducing failure rates from a costly percentage to virtually zero. This empowers you to take on more challenging and lucrative projects, such as intricate medical devices or high-performance aerospace components, that were previously too risky. Ultimately, you stop wasting time on re-runs and start increasing the throughput of reliable, high-quality parts.

Your challenges are unique, from materials and geometries to performance requirements. Moving past recurring failures requires a solution tailored to your specific application. If you’re ready to transform your brazing process from a source of frustration to a competitive advantage, our team is here to help. Let's discuss how precise thermal control can solve your most demanding joining challenges. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum