You did the research. You invested in a high-temperature furnace with an impressive spec sheet, capable of reaching 1700°C or even 1800°C. Yet, instead of being a reliable workhorse, it has become a source of constant frustration. Your material samples come out oxidized, process times are agonizingly slow, and worse, you’ve just had to replace a set of cracked heating elements for the second time this year.

The furnace hits the target temperature, so why does the process itself keep failing? You’re not alone in asking this question.

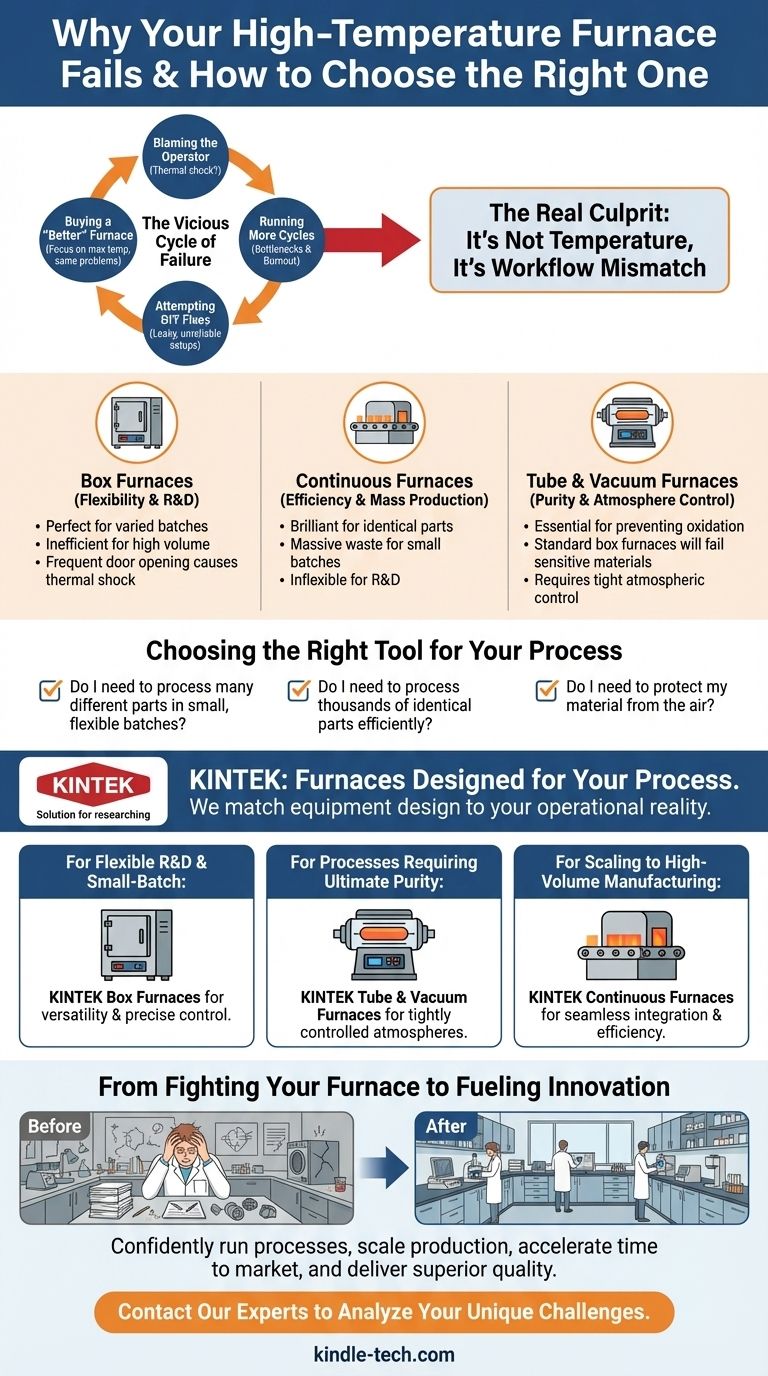

The Vicious Cycle: Why "Trying Harder" Doesn't Work

Across countless labs and production facilities, the story is the same. When a high-temperature process yields inconsistent results, teams often fall into a predictable pattern of troubleshooting:

- Blaming the Operator: "Did someone open the door too fast? It must be thermal shock."

- Running More Cycles: To meet throughput demands, teams run their batch furnace back-to-back, creating logistical bottlenecks and operator burnout.

- Attempting DIY Fixes: They might try to purge a standard box furnace with inert gas to reduce oxidation, only to find it’s an unreliable, leaky setup.

- Buying a "Better" Furnace: They replace the old model with a new one from a different brand, focusing again on the maximum temperature rating—only to find themselves facing the exact same problems six months later.

These efforts, while well-intentioned, fail to address the real issue. The commercial consequences are severe: R&D projects stall, losing weeks of work to a single failed run. Production targets are missed, delaying shipments and damaging client trust. And the budget for maintenance and repairs balloons, eating into profits.

The Real Culprit: It's Not Temperature, It's Workflow

Here is the turning point. The persistent failures, the cracked ceramics, the ruined samples—they aren't symptoms of a bad furnace. They are symptoms of a fundamental mismatch between the furnace's physical design and your operational workflow.

The industry's focus on maximum temperature has led many to believe that as long as a furnace gets hot enough, it should work. This is a costly misconception. The far more critical question is: How do you need to work with that heat?

Batch vs. Continuous: The Mismatch That Breaks Your Process

The core of the problem lies in the physical difference between furnace types, which are purpose-built for specific workflows:

-

Box Furnaces are designed for flexibility. Their front-loading door is perfect for R&D, where you might sinter a unique ceramic one day and test a metal alloy the next. However, forcing a box furnace into a high-volume, repetitive role is like using a precision screwdriver as a sledgehammer. It’s inefficient, causes excessive wear, and invites "thermal shock" because the workflow requires frequent opening and closing.

-

Continuous Furnaces are designed for efficiency. A conveyor belt moves identical parts through a stable heat zone. They are brilliant for mass production. But using one for varied, small-batch R&D is like firing up an entire automotive assembly line to build a single go-kart. It's a massive waste of energy and completely inflexible.

-

Tube & Vacuum Furnaces are designed for purity. Their sealed chambers are essential for preventing oxidation or contamination when working with sensitive materials. If your process requires this level of atmospheric control and you're using a standard box furnace, your material will fail—no matter how precise the temperature.

The "common solutions" from the previous section fail because they try to treat the symptoms (e.g., low throughput) without curing the disease (using a batch furnace for a continuous workflow).

Choosing the Right Tool for the Job, Not Just the Heat

To truly solve this problem, you must stop asking, "How hot can it get?" and start asking, "What does my process demand?"

- Do I need to process many different parts in small, flexible batches?

- Do I need to process thousands of identical parts efficiently?

- Do I need to protect my material from the air?

Answering these questions clarifies that the solution is not a generically "better" furnace, but the correctly designed furnace. This is where the right equipment partner makes all the difference.

KINTEK: Furnaces Designed for Your Process

At KINTEK, our equipment is engineered based on a deep understanding of these workflow principles. We don't just sell a box that gets hot; we provide a solution that aligns with how you work.

- For flexible R&D and small-batch production, our Box Furnaces provide the versatility and precise control needed for experimentation and testing.

- For processes requiring ultimate purity, our Tube and Vacuum Furnaces deliver the tightly controlled atmosphere necessary to prevent oxidation and contamination, ensuring material integrity.

- For scaling to high-volume manufacturing, our Continuous Furnaces are designed for seamless integration into production lines, delivering consistent and efficient thermal processing.

Our approach is to first help you diagnose your workflow. By matching the equipment's design to your operational reality, we help you eliminate the root cause of failure from day one.

From Fighting Your Furnace to Fueling Innovation

When you have the right furnace for your workflow, the transformation is immediate. The energy once spent on troubleshooting, repairs, and damage control is now freed up for what truly matters.

Imagine a lab where you can confidently run a week-long sintering process without worrying about equipment failure. Picture a production line where you can seamlessly scale from 100 units a day to 1,000, knowing your thermal process is stable and repeatable. This is the new reality when your furnace is no longer an obstacle, but a reliable partner in your work. You can take on more ambitious projects, accelerate your time to market, and deliver a level of quality that was previously out of reach.

Your work is too important to be undermined by a tool-task mismatch. If you're tired of fighting your equipment and are ready to build a more reliable and efficient thermal process, our team is here to help you analyze your unique challenges. Let's discuss your project and find the furnace that's truly built for your success. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

Related Articles

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again

- Installation of Tube Furnace Fitting Tee

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- High Pressure Tube Furnace: Applications, Safety, and Maintenance

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures