Articles

Maximizing Efficiency and Precision with Vacuum Graphite Furnaces

1 year agoDiscover how vacuum graphite furnaces revolutionize high-temperature material treatments with unmatched precision and efficiency. Explore customized solutions for various industries, advanced automation, and sustainable energy practices.

Learn More

The Ultimate Guide to the Application and Benefits of Vibratory Sieve Shaker in Laboratory Testing

1 year agoDiscover the extensive application of vibratory sieve shaker in laboratory testing for industries such as food, medicine, chemical, and more. Learn about the benefits of using a sieve shaker.

Learn More

Installation of Tube Furnace Fitting Tee

1 year agoMainly introduces the installation method of tube furnace fitting tee.

Learn More

Three-Dimensional Vibrating Sieve: Working Principle and Application Fields

1 year agoDiscover the working principle and application fields of the three-dimensional vibrating screener. Learn how this laboratory equipment uses vibration force to efficiently separate and analyze granular materials. Explore its uses in the pharmaceutical, chemical, and various other industries.

Learn More

Optimizing Performance with Graphite Vacuum Furnaces: A Comprehensive Guide

1 year agoUnlock the potential of graphite vacuum furnaces for high-temperature material treatment. Learn about their efficiency, customization options, automation, and key considerations for graphite rod usage.

Learn More

Understanding the Advantages and Disadvantages of Ball Mills in Laboratory and Industrial Applications

1 year agoDiscover the pros and cons of using ball mills for grinding materials. Explore the potential applications of ball mills for various industries.

Learn More

The Scientific Principle of Sieving: Understanding Particle Size Distribution and Laboratory Test Sieves

1 year agoLearn about the scientific principle of sieving, including the process of separating particles based on size, types of laboratory test sieves. Discover how sieving impacts various industries and the accuracy of particle sizing measurements.

Learn More

Optimizing Industrial Processes with Molybdenum Vacuum Furnaces

1 year agoDiscover the transformative potential of molybdenum vacuum furnaces in aerospace, automotive, and various other industries. Learn about their advanced features, applications, and insulation techniques for high-performance operations.

Learn More

Working Principle of Vertical Ball Mill : Impact, Attrition, and Size Reduction

1 year agoDiscover the working principle of vertical ball mills through impact and attrition mechanisms. Learn how materials like iron ore and ceramics are ground to a fine medium. Explore the construction, operations, advantages of vertical mills in this detailed guide.

Learn More

Exploring the Arc Melting Furnace: Principles, Applications, and Advantages

1 year agoDiscover the working principles, diverse applications, and advantages of the arc melting furnace. Learn about its role in laboratory settings, its ability to smelt various steels, and its high flexibility in production. Find out how electric arc furnaces work and their significance in the steel industry.

Learn More

The Advantages of Ball Milling in Laboratory Applications: high capacity and reliability

1 year agoDiscover the numerous advantages of ball milling in laboratory applications. Explore the working principles, applications, and advantages of ball mills, along with the impact of ball mill speed on size reduction. Learn how ball milling compares to traditional milling machines.

Learn More

Maximizing Efficiency and Precision with Batch Vacuum Furnaces: Options, Applications, and Parts

1 year agoExplore the diverse options and applications of batch vacuum furnaces for precise thermal processes such as annealing, brazing, and heat treatment. Learn about advanced software, data loggers, and vacuum furnace parts for research and development purposes.

Learn More

Exploring Rotary Tube Furnaces: A Comprehensive Guide

1 year agoDiscover the workings of rotary tube furnaces, their diverse applications, and key advantages. Explore how these furnaces operate, their suitability for different processes, and factors to consider when selecting one. Find out why rotary tube furnaces are favored in advanced materials processing.

Learn More

Unlocking Efficiency: Exploring the Advantages and Applications of Rotary Tube Furnaces

1 year agoDiscover the benefits of rotary tube furnaces for advanced materials processing and industrial applications. Learn about their unique features, working principles, and diverse uses in various industries, from metallurgy to catalyst synthesis.

Learn More

Exploring the Advantages of Rotary Tube Furnaces in Industrial and Laboratory Applications

1 year agoDiscover the benefits of rotary tube furnaces in various industrial and laboratory settings. Learn about the different types, customization options, and advantages such as precise temperature control and efficient heating.

Learn More

Exploring the Functions and Advantages of Rotary Tube Furnaces

1 year agoDiscover how rotary tube furnaces work and why they are used in advanced materials processing. Learn about the basic technique of rotary furnaces and their customizable features. Explore the advantages of rotary tube furnaces over other furnace types.

Learn More

Unlocking Efficiency: The Ultimate Guide to Rotary Tube Furnaces

1 year agoDiscover the transformative power of rotary tube furnaces for your heat treatment processes. Learn about the advantages, considerations, and key elements for selecting the perfect furnace for your needs. Whether it's maximizing temperature control or optimizing material handling, find out why rotary tube furnaces are the go-to solution for diverse applications.

Learn More

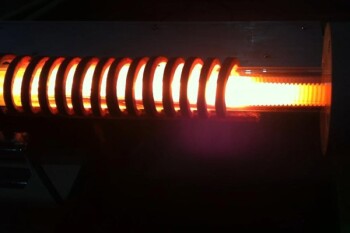

Understanding Electric Heating Systems(1): How Electric Furnaces Work and Their Advantages

1 year agoDiscover how electric heating systems, particularly electric furnaces, work efficiently without the need for flues or chimneys. Explore the benefits and components of electric furnaces, including heating elements, contactors, sequencers, and transformers.

Learn More

Understanding Electric Heating Systems(2): From Furnaces to Heating Elements

1 year agoDiscover how electric heating systems work, from electric furnaces to heating element basics. Learn about the benefits of electric heating and why it's a viable option for various applications. Find insights on heat treating furnaces and their subassemblies.

Learn More

Electric Heating Systems(3): Understanding, Benefits, and Applications

1 year agoExplore the world of electric heating systems, including electric furnaces, heating elements, and their benefits. Learn about the advantages, disadvantages, and applications of electric heating technology. Discover how electric heating systems work and their role in modern heating solutions.

Learn More

Mastering Rotary Kilns: A Comprehensive Guide to Operation, Applications, and Maintenance

1 year agoUnlock the potential of rotary kilns with our comprehensive guide. Learn about their versatile applications, from industrial sintering to organic combustion. Discover how they work, the difference between direct and indirect kilns, and the wide range of fuels they can utilize. Whether you're in cement production or specialized thermal processing, this guide will equip you with the knowledge to optimize your rotary kiln operations.

Learn More

A Comprehensive Guide to Rotary Kilns: Applications, Types, and Working Principles

1 year agoDiscover the diverse applications of rotary kilns across industries such as carbon products manufacturing and industrial sintering. Learn about different types of rotary kilns and their working principles, along with insights into laboratory furnaces and pyrolysis furnaces.

Learn More

Optimizing Industrial Processes: Rotary Kiln and Laboratory Furnace Solutions

1 year agoDiscover how rotary kilns and laboratory furnaces revolutionize industrial processes. Learn about rotary kiln sizing and design, laboratory furnace features, and industries served. Explore the production of carbon products like biochar and activated carbon.

Learn More

Vacuum Hot Press Furnace: A Comprehensive Guide

1 year agoGain in-depth knowledge of Vacuum Hot Press Furnaces, their components, benefits, and applications in various industries. Explore how these furnaces revolutionize material processing and achieve exceptional results.

Learn More

Spark Plasma Sintering Furnace: The Ultimate Guide to SPS Furnaces

1 year agoDiscover the world of Spark Plasma Sintering Furnaces (SPS). This comprehensive guide covers everything from its advantages and applications to its process and equipment. Learn how SPS furnaces can revolutionize your sintering operations.

Learn More

Unveiling Vacuum Graphite Furnaces: Performance, Applications, and Expert Insights

1 year agoDelve into the world of vacuum graphite furnaces, exploring their exceptional performance, diverse applications, and crucial considerations. Our expert insights empower you to make informed decisions for your laboratory's high-temperature material treatment needs.

Learn More

Comprehensive Guide to Tube Furnaces: Types, Applications, and Considerations

1 year agoDelve into the realm of tube furnaces, exploring their types, diverse applications in industries and laboratories, and crucial factors to consider for optimal usage.

Learn More

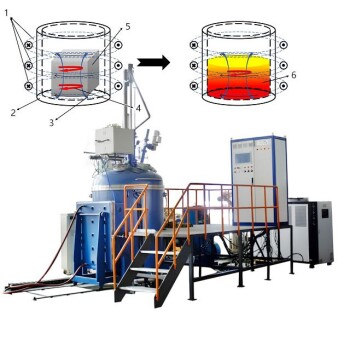

Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

1 year agoDiscover the intricacies of vacuum induction melting furnaces, their components, operation, advantages, and applications. Explore how these furnaces revolutionize metal processing and achieve exceptional material properties.

Learn More

Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

1 year agoDiscover the Vacuum Induction Melting Furnace, a specialized equipment that employs vacuum and induction heating to refine metals and alloys, ensuring high purity and precise composition control. Explore its principle, advantages, applications, and components in this comprehensive guide.

Learn More

Advantages and Disadvantages of Chemical Vapor Deposition (CVD)

1 year agoChemical vapor deposition (CVD) is a versatile thin-film deposition technique widely used in various industries. Explore its advantages, disadvantages, and potential new applications.

Learn More