Yes, brazing fumes can be highly toxic. The level of hazard is not inherent to the process itself but is dictated entirely by the composition of the materials you are heating. The specific filler metal, flux, and any coatings on the base metal determine the type and severity of the fumes produced.

The core principle of brazing safety is this: you are heating metals and chemicals to the point where they can enter the air you breathe. Understanding exactly what is in your filler rod, flux, and base metal is the only way to effectively mitigate the significant health risks involved.

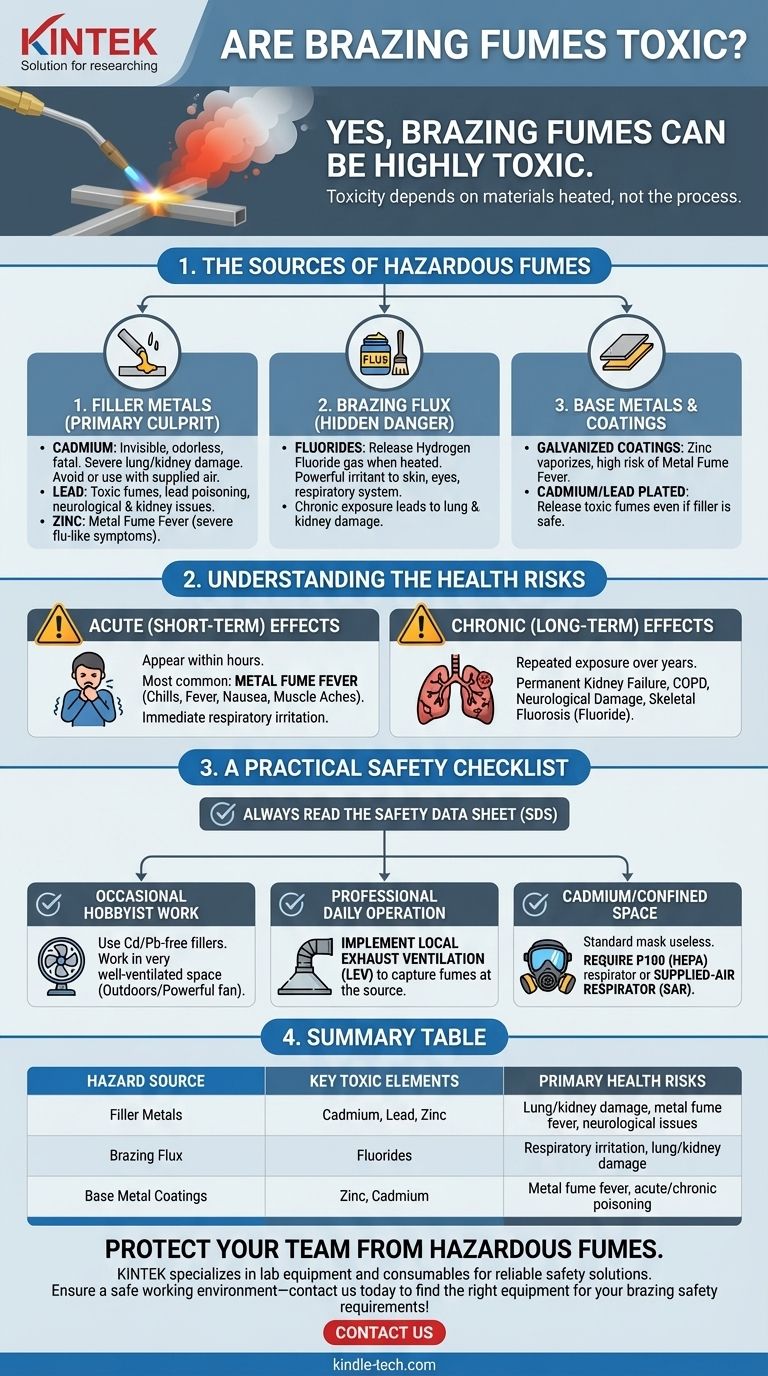

The Sources of Hazardous Fumes

The toxic substances released during brazing originate from three distinct sources. Ignoring any one of them can lead to a false sense of security.

Filler Metals (The Primary Culprit)

The filler metal is often the most significant source of hazardous fumes because it is designed to melt at a lower temperature than the base metals.

Cadmium is the most notorious hazard in brazing alloys. It is an extremely toxic heavy metal that produces a fume you cannot see or smell. Inhaling it can cause severe, irreversible lung and kidney damage, and can be fatal even from short-term overexposure. Cadmium-bearing fillers should be avoided unless absolutely required by a specific engineering print, and only used with supplied-air respiration.

Lead is another common heavy metal in some solder and brazing alloys. Its fumes are toxic and can lead to lead poisoning, which causes neurological damage, kidney problems, and other systemic health issues.

Zinc is frequently found in brazing alloys and as a coating on galvanized steel. Inhaling zinc oxide fumes can cause an acute illness known as metal fume fever, with symptoms that mimic a severe flu.

Brazing Flux (The Hidden Danger)

Flux is essential for cleaning the joint, but it contains chemicals that produce hazardous fumes when heated.

Many fluxes contain fluorides to deoxidize the metal surface. When heated, these compounds can release hydrogen fluoride gas, which is a powerful irritant to the skin, eyes, and respiratory system. Chronic exposure can lead to lung and kidney damage.

Base Metals and Coatings

The material you are joining can also be a significant source of fumes, especially if it has a surface coating.

Galvanized coatings (zinc) will vaporize at brazing temperatures, creating a dense white smoke of zinc oxide and leading to a high risk of metal fume fever. Similarly, any parts that are plated with cadmium or lead will release those toxic metal fumes when heated, even if the filler metal itself is safe.

Understanding the Health Risks

Exposure to brazing fumes can cause both immediate and long-term health problems. Recognizing the symptoms is a critical part of workplace safety.

Acute (Short-Term) Effects

These symptoms can appear within hours of exposure.

The most common is metal fume fever, characterized by chills, fever, nausea, and muscle aches. It is often mistaken for the flu and is typically caused by zinc exposure. You may also experience immediate irritation of the throat, coughing, and shortness of breath from flux or metal fumes.

Chronic (Long-Term) Effects

Repeated exposure over months or years can lead to devastating health consequences that are often irreversible.

This is the primary danger of working with metals like cadmium and lead. Chronic exposure can lead to permanent kidney failure, chronic obstructive pulmonary disease (COPD), and neurological damage. Fluoride exposure over time can lead to a bone disease called skeletal fluorosis.

A Practical Safety Checklist

Your approach to safety should match the frequency of your work and the materials you use. The non-negotiable first step is always to read the Safety Data Sheet (SDS) for your filler metal and flux.

- If your primary focus is occasional hobbyist work: Prioritize using cadmium-free and lead-free filler metals. Always work in a very well-ventilated space, such as outdoors or with a powerful fan exhausting fumes away from your breathing zone.

- If your primary focus is professional daily operation: Ventilation is not enough. You must implement Local Exhaust Ventilation (LEV), which uses a snorkel or hood to capture fumes directly at the source before they can spread.

- If you must use cadmium-bearing fillers or work in a confined space: A standard dust mask is useless. You require a properly fitted respirator with P100 (HEPA) filters for metal particulates and potentially chemical cartridges for vapors, or preferably, a supplied-air respirator (SAR).

By understanding your materials and controlling your environment, you can execute precise brazing work without compromising your health.

Summary Table:

| Hazard Source | Key Toxic Elements | Primary Health Risks |

|---|---|---|

| Filler Metals | Cadmium, Lead, Zinc | Lung/kidney damage, metal fume fever, neurological issues |

| Brazing Flux | Fluorides | Respiratory irritation, lung/kidney damage |

| Base Metal Coatings | Zinc, Cadmium | Metal fume fever, acute/chronic poisoning |

Protect your team from hazardous brazing fumes. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable safety solutions. Ensure a safe working environment—contact us today to find the right equipment for your brazing safety requirements!

Visual Guide

Related Products

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Which metal can withstand high temperatures? Selecting the Right Material for Extreme Heat

- What role do high-temperature furnaces play in RAFM steel pretreatment? Achieve Precise Microstructural Stability

- What is the significance of the vacuum cooling step in graphene/TiO2 synthesis? Ensure High-Performance Composites

- What is the sintering process of powder metallurgy? Transform Powder into Durable Metal Parts

- What is the difference between annealing and hardening? Master the Key Heat Treatment Processes

- What is the pressure less sintering method? Achieve Complex Shapes Without High-Pressure Equipment

- What role does a high-vacuum furnace environment play in W-Cu combustion synthesis? Ensure Defect-Free Density

- What critical processing conditions do high-temperature industrial furnaces provide for P91 PWHT? Ensure Joint Integrity