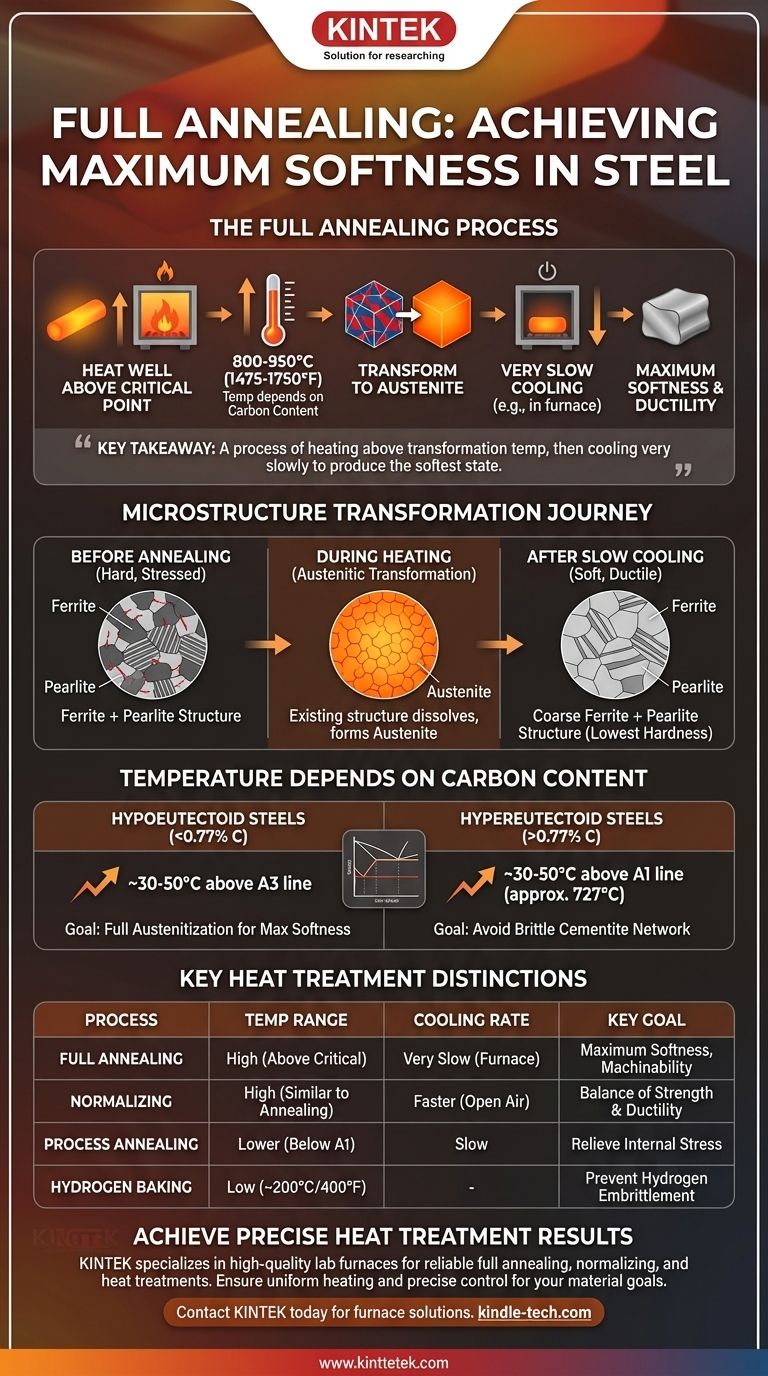

For full annealing, steel is heated to a temperature well above its critical point, followed by very slow cooling. This temperature is not a single value but depends on the steel's carbon content, typically ranging from 800-950°C (1475-1750°F). The goal is to completely transform the steel's internal crystal structure to achieve maximum softness and ductility.

The critical takeaway is that full annealing is not defined by a single temperature but by a process: heating the steel above its specific upper transformation temperature until its microstructure is fully converted to austenite, then cooling it slowly to produce the softest possible state.

The Goal of Full Annealing: Maximum Softness

The primary purpose of full annealing is to "reset" the steel to its softest, most ductile, and most stress-free condition. It is often performed on steel that has been work-hardened or needs to undergo significant shaping or machining.

The Role of Microstructure

Before annealing, a typical carbon steel consists of a microstructure of ferrite (pure, soft iron) and pearlite (a layered structure of ferrite and hard iron carbide). The arrangement and size of these structures determine the steel's properties.

The Austenitic Transformation

The key to full annealing is heating the steel above its critical temperature. This causes the existing ferrite and pearlite to dissolve and transform into a completely new crystal structure called austenite. This transformation erases the previous microstructure and its associated hardness.

The Importance of Slow Cooling

After the steel is fully austenitic, it must be cooled very slowly, often by leaving it inside the turned-off furnace. This slow cooling allows the austenite to transform back into a very coarse and uniform structure of ferrite and pearlite, which results in the lowest possible hardness and highest ductility.

Why Temperature Depends on Carbon Content

The exact annealing temperature is determined by the steel's position on the iron-carbon phase diagram. This diagram maps the steel's microstructure at different temperatures and carbon concentrations.

For Hypoeutectoid Steels (<0.77% Carbon)

These common steels are heated to approximately 30-50°C (50-90°F) above the upper critical temperature (A3 line). This ensures that all the original ferrite and pearlite transform completely into a uniform austenitic structure.

For Hypereutectoid Steels (>0.77% Carbon)

These higher-carbon steels are heated to 30-50°C (50-90°F) above the lower critical temperature (A1 line), which is around 727°C (1341°F). Heating higher is avoided because it can lead to the formation of a brittle network of cementite upon cooling.

Understanding Key Distinctions and Trade-offs

Full annealing is a specific, high-temperature process. It is often confused with other heat treatments that have different goals and temperature ranges.

Full Annealing vs. Normalizing

Normalizing uses similar heating temperatures to full annealing but involves cooling the steel in open air. This faster cooling rate produces a harder and stronger material compared to the extreme softness achieved by full annealing.

Full Annealing vs. Process Annealing

Process annealing, or stress-relief annealing, is performed at a much lower temperature, below the critical A1 point. It does not create austenite; its only goal is to relieve internal stresses from manufacturing without significantly changing the steel's hardness or microstructure.

The Misconception of Low-Temperature Baking

A process like heating at 200°C (400°F) is not annealing for softness. This is a low-temperature "baking" treatment specifically designed to remove trapped hydrogen atoms from the steel's crystal lattice. This is done to prevent a failure mechanism known as hydrogen embrittlement and has no effect on the steel's softness or ductility.

Making the Right Choice for Your Goal

Selecting the correct heat treatment is critical for achieving the desired material properties for your application.

- If your primary focus is maximum softness and machinability: Full annealing is the correct process, requiring high temperatures and very slow cooling.

- If your primary focus is a balance of strength and ductility: Normalizing is a faster and more economical alternative to full annealing.

- If your primary focus is only to remove internal stress from forming or welding: Stress-relief annealing at a lower temperature is the proper choice.

- If your primary focus is preventing delayed fracture in high-strength steels: Low-temperature baking for hydrogen removal is the specific, necessary treatment.

Ultimately, choosing the right thermal process requires understanding your starting material and your final performance goal.

Summary Table:

| Steel Type | Carbon Content | Annealing Temperature Range | Key Goal |

|---|---|---|---|

| Hypoeutectoid | < 0.77% C | ~30-50°C above A3 line | Full austenitization for maximum softness |

| Hypereutectoid | > 0.77% C | ~30-50°C above A1 line | Avoid brittle cementite network |

Achieve precise and consistent heat treatment results for your laboratory or production needs.

Whether you are processing steel samples for research or preparing materials for manufacturing, the correct annealing temperature is critical for achieving the desired material properties. KINTEK specializes in high-quality lab furnaces and thermal processing equipment, offering the precise temperature control and uniform heating required for reliable full annealing, normalizing, and other heat treatments.

Our expertise in lab equipment ensures you have the right tools to reset your steel to its softest state, improve machinability, or relieve internal stresses. Let us help you select the perfect furnace for your specific application and material goals.

Contact KINTEK today to discuss your heat treatment requirements and discover how our solutions can enhance your process efficiency and material quality.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a vacuum drying oven in pre-treating granite? Ensure Data Integrity with Low-Temp Precision

- What environments does a high-vacuum furnace provide for h-BN synthesis? Master High-Purity Nanopowder Production

- What is the difference between combustion pyrolysis and gasification? A Guide to Thermal Conversion Technologies

- Is an advantage of vacuum heat treatments reduced scaling and decarburization? Achieve Pristine, Clean Metal Parts

- What critical process conditions does a vacuum sintering furnace provide for titanium? Expert Diffusion Bonding Guide

- What materials can be tempered? Unlock the Key to Hardness and Toughness in Steel

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- How does a high-temperature furnace contribute to the PWHT of 2.25Cr-1Mo steel? Ensure Weld Integrity and Stability