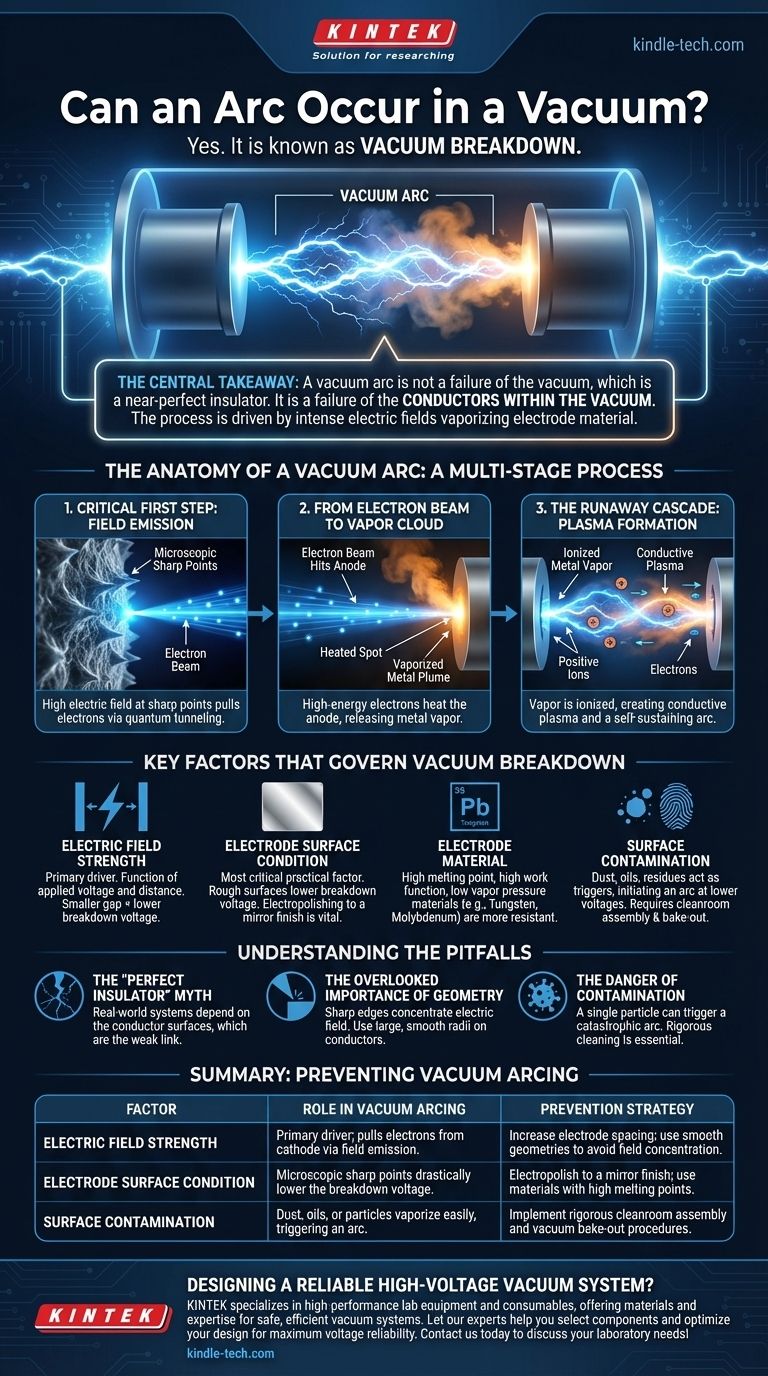

Contrary to common intuition, an electrical arc can absolutely occur in a vacuum. This phenomenon, known as vacuum breakdown, is fundamentally different from an arc in air. Instead of the surrounding gas breaking down, the high electric field forces the electrode materials themselves to become the source of the arc, creating a conductive channel of vaporized metal.

The central takeaway is that a vacuum arc is not a failure of the vacuum, which is a near-perfect insulator. It is a failure of the conductors within the vacuum. The entire process is driven by the electric field becoming so intense that it rips electrons and then vaporizes material directly from the electrode surfaces to create the very medium it needs to form an arc.

The Anatomy of a Vacuum Arc

To understand how to prevent a vacuum arc, we first need to understand its distinct lifecycle. It's a multi-stage process where the electrodes provide their own "fuel."

The Critical First Step: Field Emission

The process begins on the surface of the negative electrode (the cathode). Even on a highly polished surface, microscopic sharp points or "whiskers" exist.

A high electric field concentrates intensely at these tiny points. When the field is strong enough (millions of volts per meter), it can pull electrons directly out of the metal surface through a quantum mechanical effect called Fowler-Nordheim tunneling.

From Electron Beam to Vapor Cloud

These liberated electrons are accelerated across the vacuum gap by the high voltage, forming a tightly focused beam.

This beam of high-energy electrons slams into the positive electrode (the anode), rapidly heating a small spot. If the energy is sufficient, this spot can be heated to its boiling point, releasing a plume of vaporized metal into the vacuum gap.

The Runaway Cascade: Plasma Formation

This newly created cloud of metal vapor is the missing ingredient. The field-emitted electrons can now collide with and ionize these metal atoms.

This ionization creates a conductive plasma—a mix of positive metal ions and more free electrons. The positive ions are accelerated back toward the cathode, striking it and causing more heating, sputtering, and the release of even more electrons. This creates a self-sustaining, runaway cascade that we see as a brilliant arc.

Key Factors that Govern Vacuum Breakdown

Unlike in air, where breakdown voltage is fairly predictable, vacuum breakdown is highly dependent on the condition and preparation of the system.

Electric Field Strength

This is the primary driver. It's a function of both the applied voltage and the distance between the electrodes. A smaller gap requires a lower voltage to achieve the same critical field strength.

Electrode Surface Condition

This is arguably the most critical practical factor. A rough, unpolished, or machined surface is covered in microscopic sharp points that dramatically lower the voltage required to initiate field emission. This is why components for high-voltage vacuum use are often electropolished to a mirror finish.

Electrode Material

The choice of metal matters. Materials with a high melting point, high work function, and low vapor pressure (like tungsten or molybdenum) are more resistant to arcing than materials like aluminum or copper.

Surface Contamination

Any foreign material—dust particles, oils from fingerprints, or residual cleaning solvents—can easily vaporize when struck by electrons. These contaminants act as a "trigger," initiating an arc at a much lower voltage than the clean electrode material would allow.

Understanding the Pitfalls

Designing for high-voltage in a vacuum requires a shift in thinking away from the properties of a gas and toward the properties of solid materials under extreme stress.

The "Perfect Insulator" Myth

While a perfect vacuum is a perfect insulator, a real-world system is not. Your system's insulation is only as good as the surfaces of the conductors within it. The electrodes are always the weak link.

The Overlooked Importance of Geometry

Engineers must be obsessed with component geometry. Any sharp edge or corner on a conductor will concentrate the electric field, becoming a potential site for field emission. All high-voltage conductors should have large, smooth radii.

The Danger of Contamination

In atmospheric systems, a little dust might be harmless. In a high-voltage vacuum system, a single microscopic particle can be the seed for a catastrophic arc. This is why rigorous cleanroom assembly and vacuum bake-out procedures (heating the system under vacuum to drive off contaminants) are standard practice.

How to Prevent Vacuum Arcing in Your Design

Your strategy for preventing breakdown depends directly on your system's primary requirements.

- If your primary focus is maximizing voltage reliability: Prioritize electrode material selection (e.g., tungsten or stainless steel) and meticulous surface preparation, including electropolishing to remove microscopic sharp points.

- If your primary focus is designing a practical system: Focus on component geometry by using large, smooth radii on all conductors and ensuring sufficient spacing well beyond the theoretical minimum to lower the overall electric field.

- If your primary focus is long-term operational stability: Implement rigorous cleaning and vacuum bake-out procedures to remove all surface contaminants and absorbed gases before sealing or operating the system.

Ultimately, managing the risk of a vacuum arc is about controlling the surfaces within the void, not the void itself.

Summary Table:

| Factor | Role in Vacuum Arcing | Prevention Strategy |

|---|---|---|

| Electric Field Strength | Primary driver; pulls electrons from cathode via field emission. | Increase electrode spacing; use smooth geometries to avoid field concentration. |

| Electrode Surface Condition | Microscopic sharp points drastically lower the breakdown voltage. | Electropolish to a mirror finish; use materials with high melting points. |

| Surface Contamination | Dust, oils, or particles vaporize easily, triggering an arc. | Implement rigorous cleanroom assembly and vacuum bake-out procedures. |

Designing a reliable high-voltage vacuum system?

Preventing vacuum arcing requires precise control over electrode materials, surface finishes, and assembly cleanliness. KINTEK specializes in high-performance lab equipment and consumables, offering the materials and expertise to ensure your vacuum systems operate safely and efficiently.

Let our experts help you select the right components and optimize your design for maximum voltage reliability. Contact us today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the 5 methods of carburizing? A Guide to Choosing the Right Case-Hardening Process

- What is the process of consumable electrode arc melting? A Guide to High-Purity Alloy Refining

- How does high-temperature solution treatment optimize 27% Cr super duplex steel? Achieve Peak Microstructural Integrity

- How will you differentiate between solid state sintering and liquid phase sintering? Achieve Optimal Density and Efficiency

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is the high temperature of a vacuum furnace? Pushing Thermal Limits for Advanced Materials

- What could happen if you overheated the brazing joint before adding filler metal? Avoid These Common Brazing Failures

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space