In short, yes. Not only can graphene be made artificially, but virtually all of the graphene used in research and commercial applications is made through artificial synthesis. Graphene does not exist as a standalone, mineable material; it must be intentionally isolated from graphite or grown atom-by-atom.

The central challenge is not if we can create graphene, but how to produce it at the right scale, with consistent quality, and at a cost that makes it viable for a specific application. The manufacturing method you choose directly defines the material's properties and its ultimate use.

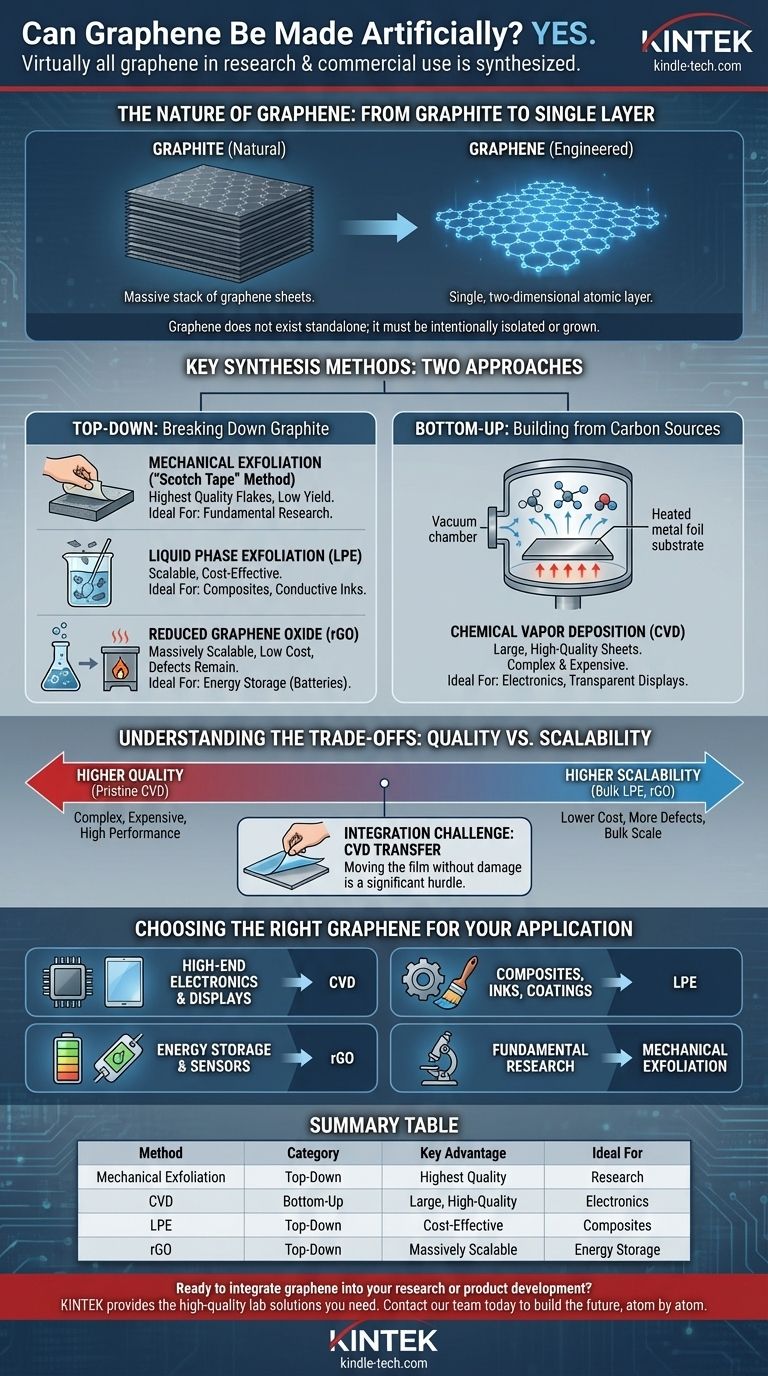

The Nature of Graphene: From Graphite to Single Layer

What is Graphene, Fundamentally?

Graphene is a single, two-dimensional layer of carbon atoms arranged in a honeycomb lattice. The most intuitive way to understand this is to picture a block of graphite, the material found in pencils.

Graphite is essentially a massive stack of individual graphene sheets held together by weak forces. While graphite is a natural material, a single, isolated sheet with its remarkable properties is graphene, and it requires a deliberate process to create.

Why 'Artificial' is the Only Way

You cannot find a sheet of graphene in nature the way you might find a gold nugget. The process of isolating one single atomic layer from a stack of billions (graphite) or building it from the ground up is inherently a man-made, or "artificial," engineering feat.

Every method of obtaining usable graphene is a form of synthesis or fabrication.

Key Methods of Graphene Synthesis

There are several primary methods for producing graphene, each with distinct advantages and disadvantages. They are generally categorized as "top-down" (starting with graphite and breaking it down) or "bottom-up" (building graphene from carbon sources).

Mechanical Exfoliation (The 'Scotch Tape' Method)

This is the original, Nobel Prize-winning "top-down" method. It involves using adhesive tape to peel away layers from a piece of graphite until only a single, atomic-thin layer remains.

This technique produces extremely high-quality, pristine graphene flakes. However, it is a manual, low-yield process that is impossible to scale for industrial production. It remains a vital tool for fundamental laboratory research.

Chemical Vapor Deposition (CVD)

CVD is a "bottom-up" approach and the leading method for producing large, high-quality graphene sheets. In this process, a substrate, typically copper or nickel foil, is heated in a vacuum chamber and exposed to a carbon-containing gas like methane.

The high temperature breaks the gas molecules apart, and the carbon atoms reassemble on the surface of the metal foil as a continuous, single layer of graphene. This method is the standard for applications requiring large films, such as electronics, transparent conductive screens, and sensors.

Liquid Phase Exfoliation (LPE)

LPE is a scalable "top-down" method for bulk production. It involves subjecting graphite to high-shear forces in a specific liquid solution. This process breaks the graphite apart, creating a dispersion of graphene flakes, which are often a few layers thick.

While not producing the perfect single-layer sheets of CVD, LPE is highly scalable and cost-effective. It is ideal for applications where bulk material is needed, such as in conductive inks, polymer composites, and industrial coatings.

Chemical Reduction of Graphene Oxide (rGO)

This is another highly scalable, low-cost "top-down" chemical process. First, graphite is aggressively oxidized to produce graphene oxide (GO), a material rich in oxygen-containing functional groups that is easily dispersed in water.

This GO is then chemically or thermally "reduced" to remove the oxygen and restore the conductive graphene structure, resulting in reduced graphene oxide (rGO). The process leaves behind some structural defects, so rGO is not as conductive as pristine graphene. However, its low cost and massive scalability make it excellent for energy storage (batteries, supercapacitors), biosensors, and large-area composites.

Understanding the Trade-offs: Quality vs. Scalability

The term "graphene" is often used as a catch-all, but the material produced by different methods varies significantly. Understanding this spectrum is critical.

The 'Graphene' Quality Spectrum

Not all graphene is created equal. Pristine, single-layer graphene made by CVD has vastly different electronic properties from the multi-layer, defect-containing flakes of reduced graphene oxide.

When evaluating a product claiming to use graphene, the first question should always be: what kind of graphene is it, and how was it made? The answer determines its true performance.

Cost vs. Performance

There is a direct trade-off between material perfection, scalability, and cost.

- High Performance: CVD produces the best quality for electronics but is a more complex and expensive process.

- Bulk Scale: LPE and rGO synthesis are far cheaper and can produce tons of material, but this material is less perfect and is not suitable for high-end electronics.

The Challenge of Integration

A major hurdle, particularly for CVD graphene, is not just synthesis but also transfer. The graphene film is grown on a metal substrate (like copper) and must be carefully transferred to its final destination (like a silicon wafer or flexible plastic) without tearing, wrinkling, or introducing contamination. This transfer step is a significant engineering challenge.

Choosing the Right Graphene for Your Application

Selecting the correct type of graphene is entirely dependent on your end goal. The method of synthesis dictates the material's form, function, and feasibility.

- If your primary focus is high-performance electronics or transparent displays: CVD is the established method for producing the required large, high-quality, single-layer sheets.

- If your primary focus is strengthening composites, creating conductive inks, or industrial coatings: Liquid Phase Exfoliation (LPE) provides the bulk quantities of graphene platelets needed for these applications cost-effectively.

- If your primary focus is large-scale energy storage or certain types of sensors: Reduced Graphene Oxide (rGO) offers a powerful balance of low cost, massive scalability, and sufficient properties.

- If your primary focus is fundamental scientific research: Mechanical exfoliation remains a key tool for creating the highest-quality, defect-free flakes for discovery.

Understanding the synthesis method is the key to unlocking the true potential of graphene for any specific goal.

Summary Table:

| Method | Category | Key Advantage | Ideal For |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Highest Quality, Pristine Flakes | Fundamental Research |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Large, High-Quality Sheets | Electronics, Transparent Displays |

| Liquid Phase Exfoliation (LPE) | Top-Down | Cost-Effective, Bulk Production | Composites, Conductive Inks, Coatings |

| Reduced Graphene Oxide (rGO) | Top-Down | Massively Scalable, Low Cost | Energy Storage, Biosensors |

Ready to integrate graphene into your research or product development?

The choice of synthesis method is critical to your project's success. At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed for advanced materials research, including graphene synthesis and analysis.

Our experts can help you select the right tools for your specific method, whether you're scaling up with CVD or optimizing a bulk process with LPE.

Contact our team today to discuss how we can support your laboratory's innovation in materials science. Let's build the future, atom by atom.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- Are all lab grown diamonds CVD? Understanding the Two Main Methods

- How do nanotubes affect the environment? Balancing Low Carbon Footprint with Ecological Risks

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques