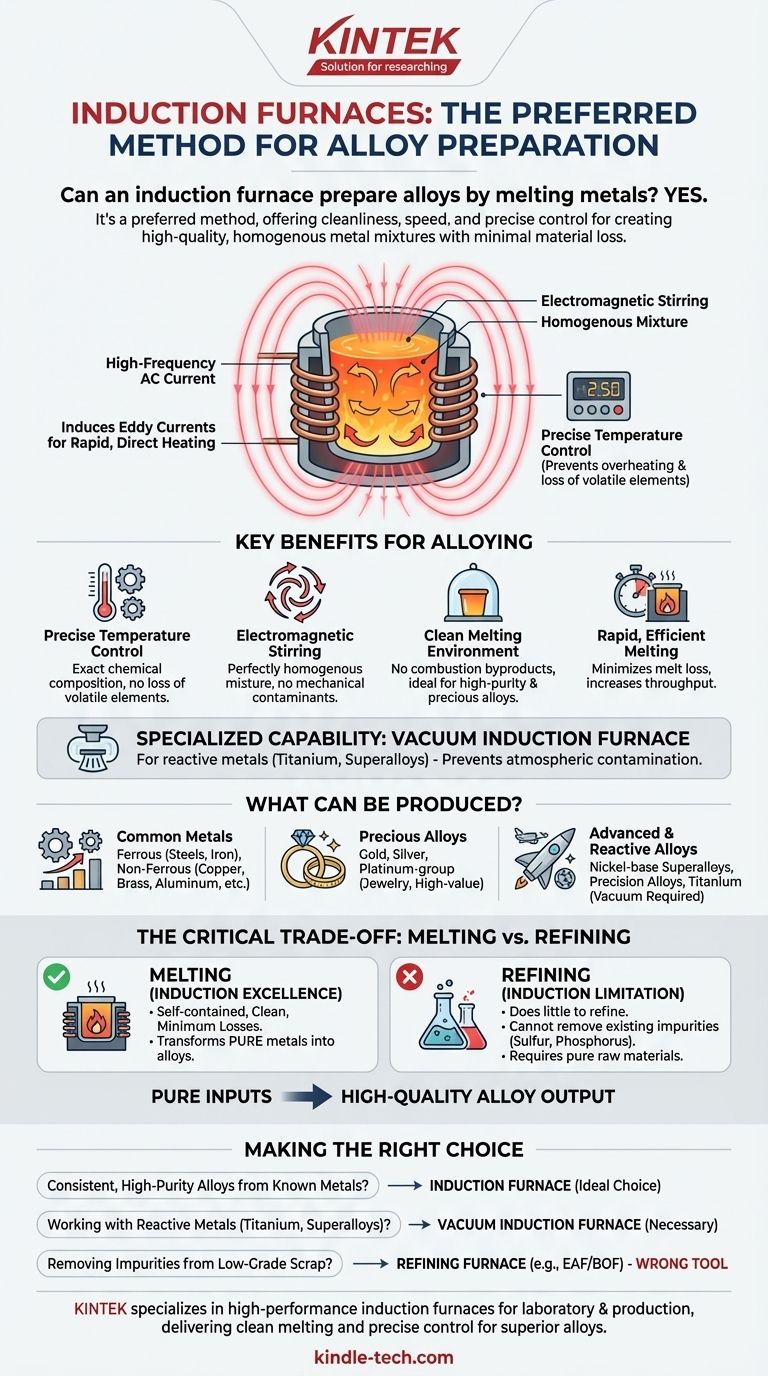

Yes, an induction furnace is not only suitable but is a preferred method for preparing high-quality alloys by melting constituent metals. Its core advantages—cleanliness, speed, and precise control—make it exceptionally well-suited for creating homogenous metal mixtures with minimal loss of material.

An induction furnace excels at melting and alloying because it offers precise control over temperature in a clean environment. Its primary function is to melt and mix, not to refine, meaning the purity of your final alloy is determined by the purity of the raw materials you use.

How Induction Furnaces Enable Precise Alloying

The effectiveness of an induction furnace for alloying stems directly from its unique heating mechanism. It is not about external flames or heating elements, but about generating heat directly within the material itself.

The Principle of Induction Heating

An induction furnace uses a powerful, high-frequency alternating current passed through a copper coil. This coil generates a rapidly changing magnetic field around the crucible inside.

This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal charge or a graphite crucible. The material's natural resistance to these currents generates intense, rapid heat, causing it to melt from the inside out.

Unmatched Temperature Control

Because the heating is controlled electromagnetically, operators have extremely precise and instantaneous control over the temperature of the melt.

This is critical for alloying. It prevents overheating, which can burn off valuable and volatile alloying elements like zinc or magnesium, ensuring the final chemical composition of the alloy is exactly as intended.

The Benefit of Electromagnetic Stirring

A key feature of induction melting is the natural stirring action created by the magnetic fields. These forces cause the molten metal bath to move and circulate continuously.

This electromagnetic stirring is essential for creating high-quality alloys, as it ensures all constituent metals are blended thoroughly, resulting in a perfectly homogenous final product without mechanical stirrers that could introduce contaminants.

What Metals and Alloys Can Be Produced?

Induction technology is versatile, capable of handling a vast range of metals from common industrial materials to highly specialized superalloys.

Common Ferrous and Non-Ferrous Metals

Induction furnaces are widely used for melting and alloying standard metals. This includes steels, stainless steels, iron, copper, brass, aluminum, and their various alloys.

Precious Metal Alloys

The clean melting environment and minimal material loss make induction ideal for high-value materials. It is a standard tool in jewelry manufacturing for creating precise gold, silver, and platinum-group alloys.

Advanced and Reactive Alloys

For materials that react aggressively with oxygen, a specialized vacuum induction furnace is used.

This technology allows for the melting and casting of materials like nickel-base superalloys, precision alloys, titanium, and rare-earth metals under a vacuum or a protective inert atmosphere, preventing contamination and ensuring purity.

Understanding the Critical Trade-off: Melting vs. Refining

While ideal for alloying, it is crucial to understand that an induction furnace is fundamentally a melting device, not a refining one.

Why Induction Furnaces Excel at Melting

The process is self-contained and exceptionally clean. There are no combustion byproducts to contaminate the melt. The quick melting cycle and contained environment result in minimum melt losses, preserving your valuable raw materials.

The Limitation: Minimal Refining Capability

The clean, controlled environment also means the furnace does little to refine the metal. It will not remove existing impurities like sulfur, phosphorus, or unwanted oxides from the initial charge.

Refining processes typically require chemical reactions, often through the introduction of oxygen or specific slag-forming reagents, which are not part of a standard induction furnace's operation.

The Implication for Your Raw Materials

This means the quality of your input dictates the quality of your output. To produce a high-purity alloy, you must start with high-purity constituent metals. The furnace will faithfully melt and mix whatever you put into it.

Making the Right Choice for Your Goal

To determine if an induction furnace is the correct tool, you must be clear on your primary objective.

- If your primary focus is creating consistent, high-purity alloys from known-purity metals: An induction furnace is the ideal choice for its precision, cleanliness, and efficiency.

- If your primary focus is working with reactive metals like titanium or superalloys: A specialized vacuum induction furnace is necessary to prevent contamination from the atmosphere.

- If your primary focus is removing impurities from low-grade scrap metal: An induction furnace is the wrong tool; you need a dedicated refining furnace, such as an Electric Arc or Basic Oxygen Furnace.

Ultimately, the induction furnace is the definitive tool for transforming pure metals into precise, homogenous alloys.

Summary Table:

| Key Feature | Benefit for Alloy Preparation |

|---|---|

| Precise Temperature Control | Prevents loss of volatile alloying elements, ensuring exact chemical composition. |

| Electromagnetic Stirring | Creates a perfectly homogenous mixture without mechanical, contaminating stirrers. |

| Clean Melting Environment | No combustion byproducts; ideal for precious metals and high-purity alloys. |

| Rapid, Efficient Melting | Minimizes melt loss and increases throughput for common and advanced alloys. |

| Vacuum Capability (Specialized) | Enables melting of reactive metals (e.g., titanium, superalloys) without contamination. |

Ready to produce superior, homogenous alloys with precision and efficiency?

KINTEK specializes in high-performance induction furnaces for laboratory and production environments. Our equipment delivers the clean melting, precise control, and electromagnetic stirring essential for creating consistent alloys from precious metals to advanced superalloys.

Contact our experts today to discuss how our solutions can enhance your alloy development and production processes.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results