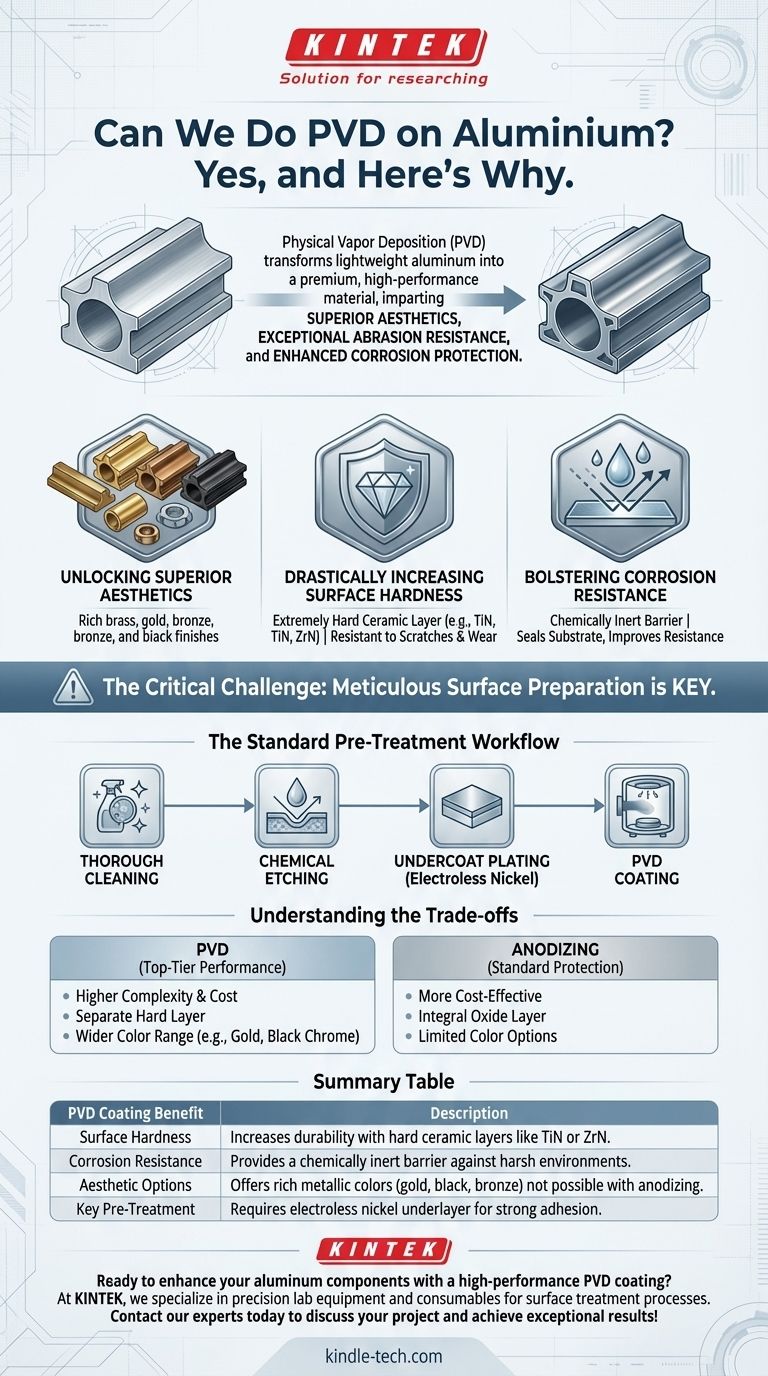

Yes, Physical Vapor Deposition (PVD) is a highly effective finishing process for aluminum. It is frequently used to impart superior aesthetic qualities, exceptional abrasion resistance, and enhanced corrosion protection to aluminum parts, transforming the lightweight metal into a premium, high-performance material.

While aluminum is an ideal candidate for the benefits of PVD coating, success is not automatic. The entire process hinges on meticulous surface preparation to overcome aluminum's natural oxide layer and ensure a flawless bond.

Why PVD is an Excellent Choice for Aluminum

PVD adds a thin, ceramic-based film to the surface of a material. For a relatively soft metal like aluminum, this addition provides three significant advantages.

Unlocking Superior Aesthetics

PVD allows for a vast range of colors and finishes that are difficult or impossible to achieve with other processes like anodizing. This includes rich metallic tones like brass, gold, bronze, and black, all with a consistent and durable finish.

This capability allows you to use lightweight, cost-effective aluminum while achieving the visual appearance of much heavier or more expensive metals.

Drastically Increasing Surface Hardness

Aluminum is a soft metal, making it susceptible to scratches and wear. PVD coatings, typically made of materials like Titanium Nitride or Zirconium Nitride, are exceptionally hard.

Applying this hard ceramic layer dramatically increases the surface durability of the aluminum part, providing excellent resistance to scratches, abrasion, and daily wear and tear.

Bolstering Corrosion Resistance

While aluminum naturally forms a protective oxide layer, it can still corrode, especially in harsh chemical or saline environments. A PVD coating acts as a chemically inert barrier.

This barrier seals the aluminum substrate from the outside environment, significantly improving its resistance to corrosion and chemical attack.

The Critical Challenge: Preparing the Aluminum Surface

You cannot apply a PVD coating directly onto raw aluminum and expect it to last. The success of the entire process depends on a multi-step pre-treatment phase designed to address the unique nature of the aluminum surface.

Understanding Aluminum's Natural Oxide Layer

When exposed to air, aluminum almost instantly forms a thin, hard, and transparent layer of aluminum oxide. While this layer provides some natural corrosion protection, it prevents PVD coatings from adhering properly.

This passive oxide layer must be completely and uniformly removed before the coating process can begin.

The Necessity of an Underlayer

To ensure a strong, permanent bond, an intermediate layer is almost always plated onto the aluminum part after the oxide layer has been removed.

This underlayer, often electroless nickel or sometimes chromium, serves as a stable and pristine foundation. It creates an ideal surface for the subsequent PVD film to adhere to, ensuring the final coating is durable and will not flake or peel.

The Standard Pre-Treatment Workflow

A typical process involves several tightly controlled steps:

- Thorough Cleaning: The part is degreased and cleaned to remove all oils and surface contaminants.

- Chemical Etching: The part is placed in a chemical bath to strip away the natural aluminum oxide layer.

- Undercoat Plating: Immediately after etching, the part is plated with an underlayer like electroless nickel.

- PVD Coating: Finally, the prepared part is placed in a vacuum chamber where the PVD coating is applied over the nickel underlayer.

Understanding the Trade-offs

PVD offers top-tier performance, but it's important to weigh the trade-offs against other common aluminum finishes.

Cost and Complexity

The multi-step process involving cleaning, etching, plating, and vacuum deposition makes PVD significantly more complex and costly than standard anodizing. The process requires specialized equipment and deep expertise to execute correctly.

Anodizing vs. PVD

Anodizing is an electrochemical process that converts the surface of the aluminum into a durable aluminum oxide layer. It is integral to the part, not a coating. PVD, in contrast, deposits a separate layer of material onto the part. PVD is generally harder and offers more color options, while anodizing is typically more cost-effective.

Importance of Quality Control

The final quality of the PVD finish is entirely dependent on the quality of the pre-treatment. Any failure in the cleaning or underplating stages will result in poor adhesion, leading to potential chipping or flaking of the hard PVD coating. Sourcing from a reputable, experienced vendor is critical.

Making the Right Choice for Your Application

Selecting the right finish depends entirely on your project's specific goals for performance, aesthetics, and cost.

- If your primary focus is cost-effective color and moderate protection: Standard Type II anodizing is an excellent and economical choice for many applications.

- If your primary focus is maximum hardness and wear resistance: PVD provides a demonstrably harder and more durable surface than any type of anodizing.

- If your primary focus is achieving specific premium colors (like gold or black chrome): PVD offers a much wider, more vibrant, and more consistent color palette.

By understanding the critical role of surface preparation, you can confidently leverage PVD to elevate your aluminum components to a new level of performance and aesthetic appeal.

Summary Table:

| PVD Coating Benefit | Description |

|---|---|

| Surface Hardness | Increases durability with hard ceramic layers like TiN or ZrN. |

| Corrosion Resistance | Provides a chemically inert barrier against harsh environments. |

| Aesthetic Options | Offers rich metallic colors (gold, black, bronze) not possible with anodizing. |

| Key Pre-Treatment | Requires electroless nickel underlayer for strong adhesion. |

Ready to enhance your aluminum components with a high-performance PVD coating? At KINTEK, we specialize in precision lab equipment and consumables for surface treatment processes. Our expertise ensures your aluminum parts receive the meticulous pre-treatment and advanced PVD coating they need for superior durability and aesthetics. Contact our experts today to discuss your project requirements and discover how we can help you achieve exceptional results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts