Yes, you can absolutely heat treat a metal part more than once. In fact, re-heat treating is a standard and often necessary practice in metallurgy. It is used to correct a previous treatment that didn't meet specifications, to alter a part's properties for subsequent manufacturing steps, or as part of a multi-stage process to achieve a highly refined final structure.

Re-heat treating is a metallurgical "reset button." Each time you properly heat a steel part above its critical temperature, you erase its previous crystalline structure, allowing you to re-form it into a new one. However, every cycle carries risks like distortion and carbon loss that must be carefully managed.

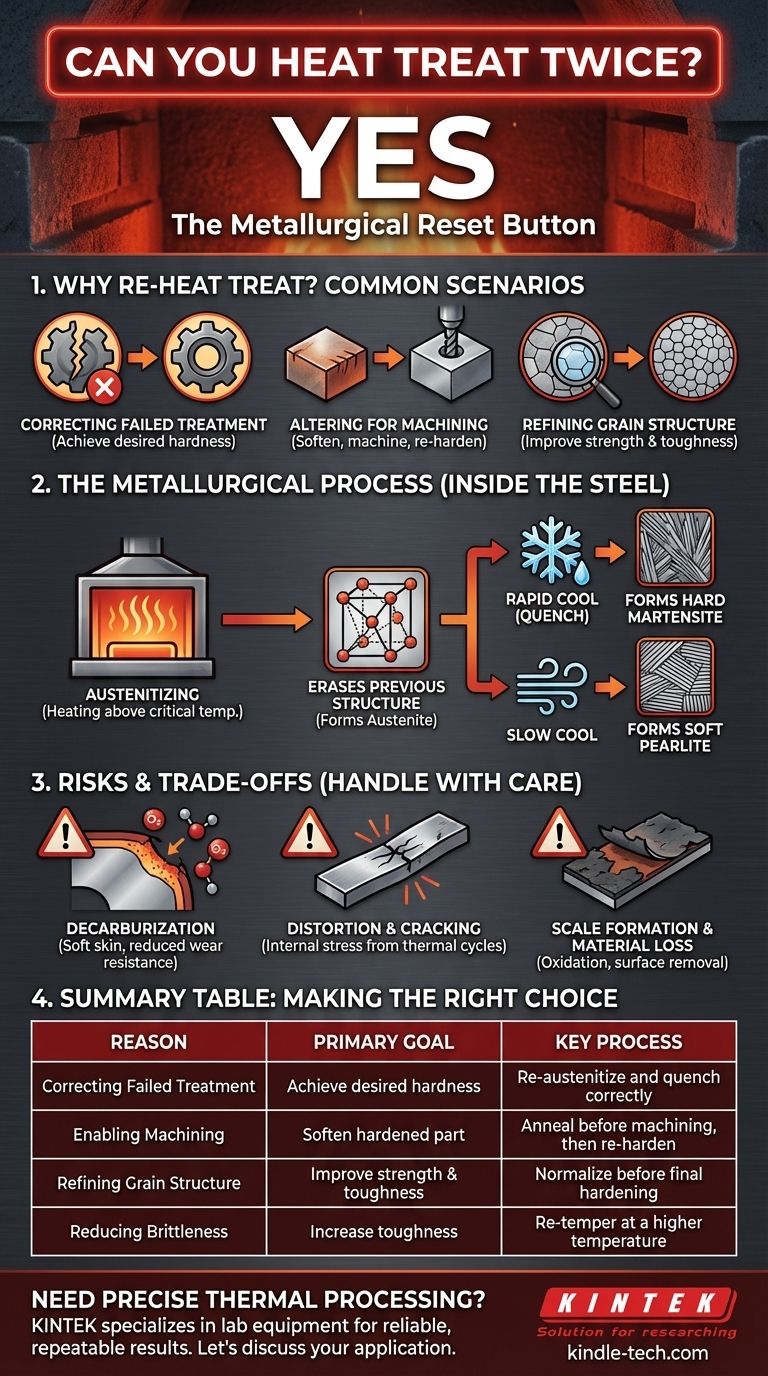

Why Re-Heat Treat? Common Scenarios

Understanding the reasons for re-heat treating reveals its importance as a corrective and strategic tool in manufacturing and metalworking.

Correcting a Failed Treatment

If a part comes out of a hardening process too soft, it means the quench was unsuccessful. This could be due to a slow cooling rate or incorrect temperature.

To fix this, the part is heated again to its critical (austenitizing) temperature and then quenched correctly. This second attempt, if successful, will produce the desired hardness.

Altering Properties for Machining

Imagine a part that has been hardened but now requires additional drilling or milling. Attempting to machine a fully hardened part is difficult, expensive, and can ruin tooling.

The solution is to perform an annealing cycle—a specific type of heat treatment that makes the metal very soft. After the part is annealed and machined, it can then be re-hardened and tempered to its final required specifications.

Refining Grain Structure

Processes like forging can leave the metal with a large, inconsistent grain structure, which can negatively impact its strength and toughness.

A heat treatment called normalizing is often performed after forging to create a smaller, more uniform grain structure. This is then followed by the final hardening and tempering cycles to achieve the desired mechanical properties. This is a planned, multi-step heat treatment process.

The Metallurgical Process: What's Happening Inside

To trust the process, you must understand what is happening at a microscopic level within the steel.

Erasing the Previous Microstructure

Heating a carbon steel part above its critical temperature (typically between 1400-1600°F or 760-870°C) transforms its internal crystal structure into a state called austenite.

This transformation effectively dissolves the previous structure, whether it was soft pearlite (from annealing) or hard martensite (from hardening). It gives the material a clean slate.

A Fresh Start for Quenching

Once the steel is fully austenitic, it is ready for the next step. The subsequent cooling rate determines the new microstructure.

A rapid cool (quench) will form hard martensite. A slow cool will form soft pearlite. This is why re-austenitizing is the key to any re-heat treatment.

Understanding the Risks and Trade-offs

While powerful, re-heat treating is not without consequences. Each thermal cycle introduces stress and potential for degradation.

Decarburization

This is one of the most significant risks. When steel is held at high temperatures in an atmosphere containing oxygen, carbon atoms can migrate from the surface of the part.

This leaves a soft, low-carbon "skin" on the component, which is detrimental to wear resistance and fatigue life. Using a controlled, oxygen-free atmosphere or specialized coatings can prevent this.

Distortion and Cracking

Each cycle of heating and rapid cooling introduces immense internal stress. This stress can cause the part to warp, twist, or change dimensions.

Complex geometries or parts with both thick and thin sections are especially vulnerable. In severe cases, particularly if the part is not tempered properly between hardening cycles, this stress can lead to cracking.

Scale Formation and Material Loss

Heating steel in the presence of air forms a dark, flaky oxide layer known as scale. This scale must be removed, typically through sandblasting or chemical pickling.

While minor, this process removes a small amount of surface material with each cycle. For high-precision parts, this material loss must be accounted for.

Making the Right Choice for Your Goal

Use the following guidelines to determine your approach.

- If your primary focus is correcting a failed hardening: Re-austenitize the part completely, then perform the quench and temper cycle again, ensuring your parameters are correct this time.

- If your primary focus is enabling machining on a hard part: Perform a full annealing cycle to make the material as soft as possible before proceeding with the final hardening treatment after machining.

- If your primary focus is refining a coarse grain structure: Use a normalizing cycle before your final hardening and tempering to achieve a tougher, more reliable end product.

- If your primary focus is reducing brittleness after hardening: A part can be re-tempered at a higher temperature to increase its toughness (at the expense of some hardness) without needing to be fully re-hardened.

Treating each thermal cycle as a deliberate and controlled step gives you the power to precisely engineer the final performance of your material.

Summary Table:

| Reason for Re-Heat Treating | Primary Goal | Key Process |

|---|---|---|

| Correcting a Failed Treatment | Achieve desired hardness | Re-austenitize and quench correctly |

| Enabling Machining | Soften hardened part | Anneal before machining, then re-harden |

| Refining Grain Structure | Improve strength & toughness | Normalize before final hardening |

| Reducing Brittleness | Increase toughness | Re-temper at a higher temperature |

Need precise thermal processing for your lab or production?

Re-heat treating requires exact temperature control to avoid decarburization, distortion, and scale formation. KINTEK specializes in the lab equipment and consumables that ensure reliable results. Our furnaces and controlled atmosphere systems are designed for the repeatable, high-quality heat treatment cycles your projects demand.

Let's discuss your specific application. Contact our thermal processing experts today to find the right solution for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How many times can you heat treat metal? Understanding the Limits of Material Integrity

- What are the disadvantages of nitriding over carburizing? A Guide to Process Limitations

- What is the function of a Drop Tube Reactor in flash-reduced iron powder study? Precision Simulation for Rapid Reduction

- What is the function of a resistance furnace in the preparation of ultrafine metallic uranium powder? Guide to HDH.

- What are two advantages of putting sinter into the furnace? Achieve Purity and Superior Strength

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- What are the advantages of using an SPS furnace for LATP? Achieve Higher Ionic Conductivity & Faster Sintering

- What is the specific danger associated with hot argon in bottom-loading vacuum furnaces? Understanding the Invisible Asphyxiation Risk