Yes, you can absolutely overload a hydraulic press, and the consequences range from accelerated wear to catastrophic, life-threatening failure. A press is not an instrument of infinite force; it is a precisely engineered system with defined structural and hydraulic limits. Exceeding its rated tonnage forces the system into a state where it must either relieve the pressure or break at its weakest point.

The immense power of a hydraulic press can create a false sense of invincibility. However, treating its maximum tonnage rating as a guideline rather than an absolute limit is a direct path to equipment damage, explosive failure, and severe personal injury.

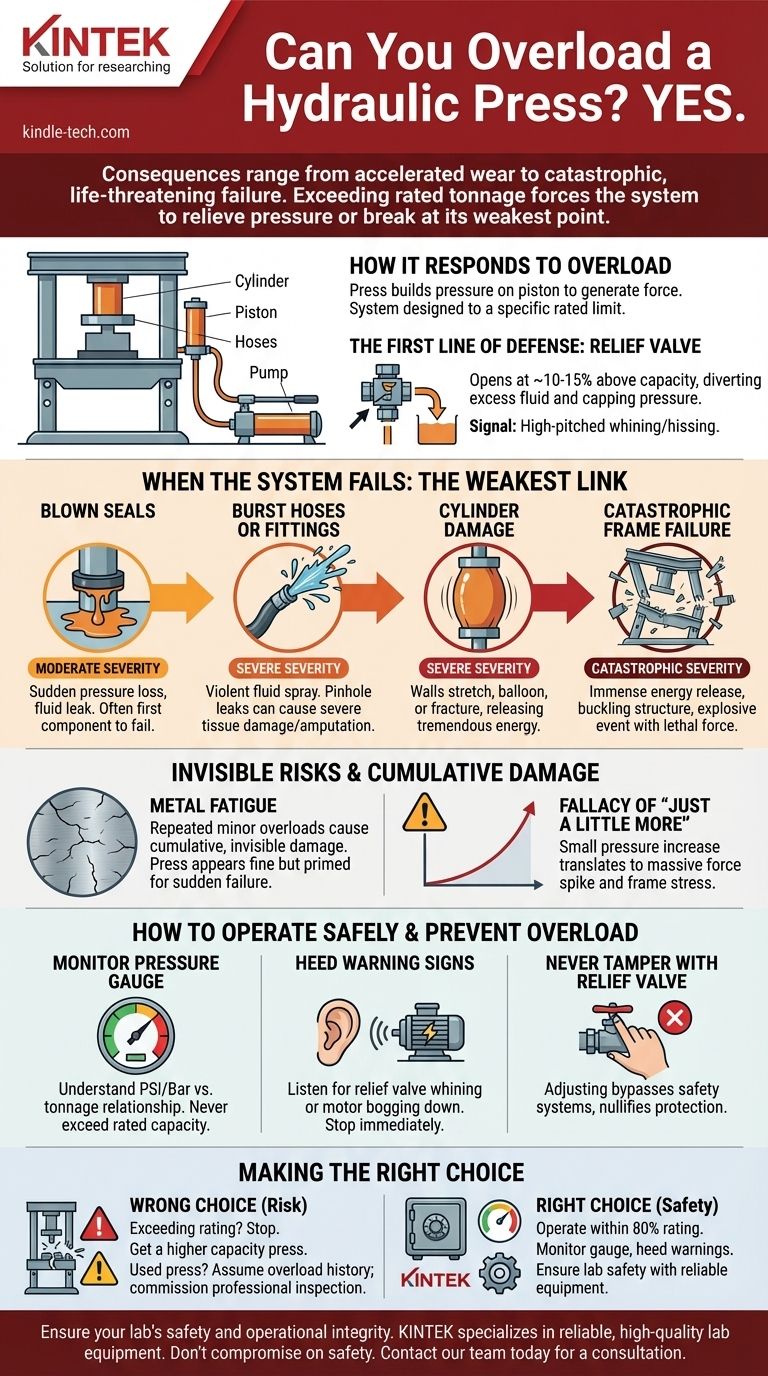

How a Press Responds to Overload

A hydraulic press operates on a simple principle: fluid is pressurized by a pump, and that pressure acts on a piston to generate immense force. The entire system—frame, cylinder, hoses, and seals—is designed to contain this pressure up to a specific, rated limit.

The First Line of Defense: The Relief Valve

Every properly designed hydraulic circuit includes a pressure relief valve. This is the system's primary safety device.

When pressure in the circuit builds to a preset level (typically 10-15% above the press's rated capacity), the relief valve opens. It diverts excess hydraulic fluid back to the reservoir, effectively capping the maximum pressure and preventing the tonnage from climbing further.

If you hear a high-pitched whining or hissing sound as the press stalls, that is often the relief valve doing its job. This is a clear signal that you have reached the machine's maximum force.

When the System Fails: The Weakest Link

If the relief valve is faulty, has been improperly adjusted, or is bypassed, the pressure will continue to build until a component fails. This failure is never predictable and always dangerous.

Blown Seals: The seals inside the hydraulic cylinder are often the first component to fail. This results in a sudden loss of pressure and a significant hydraulic fluid leak, but it is typically the least destructive failure mode.

Burst Hoses or Fittings: Hydraulic hoses can burst, releasing a violent spray of high-pressure fluid. This is extremely dangerous, as a pinhole leak can inject fluid through the skin, causing severe tissue damage, gangrene, and potential amputation.

Cylinder Damage: The cylinder walls can "balloon" or stretch under extreme pressure. In a worst-case scenario, the cylinder itself can fracture or rupture, releasing tremendous energy.

Catastrophic Frame Failure: The most dangerous outcome is the failure of the press frame. The immense stored energy is released in an instant, causing the steel structure to buckle or welds to tear apart. This is an explosive event that sends metal components flying with lethal force.

Understanding the Risks: Beyond a Single Event

Pushing a press to its limit introduces risks that extend beyond a single overload event. The real danger often lies in the cumulative damage you can't see.

Metal Fatigue and Invisible Damage

Even if the press doesn't fail catastrophically, repeated minor overloads cause metal fatigue. Microscopic cracks can form and grow within the frame's welds and structural members.

This damage is cumulative and invisible to the naked eye. A press that has been repeatedly stressed beyond its rating may appear fine but could be primed for a sudden, unexpected failure during a routine operation well below its maximum tonnage.

The Fallacy of "Just a Little More"

The force generated by a press is not linear at the top end of its capacity. A small increase in pressure can translate to a massive spike in force and stress on the frame. Thinking you can "just nudge it a little more" is a dangerous miscalculation of the physics involved.

How to Operate Safely and Prevent Overload

Respecting the machine's limits is the foundation of safe operation. Awareness and proper maintenance are your most important tools.

Always Monitor the Pressure Gauge

The pressure gauge is your most critical instrument. Understand the relationship between the system pressure (in PSI or bar) and the output force (in tons). Never allow the pressure to exceed the level that corresponds to the press's maximum rated tonnage.

Heed the Warning Signs

Listen to your equipment. If the electric motor is bogging down or the relief valve is audibly squealing, the press is telling you it has reached its limit. Do not try to force it further.

Never Tamper with the Relief Valve

The pressure relief valve is set by the manufacturer for a reason. Adjusting it to allow for higher pressure is equivalent to disabling the safety systems in your car. It nullifies all protection and puts the entire system at risk.

Making the Right Choice for Your Operation

- If your primary focus is completing a job that exceeds your press's rating: Stop immediately. The only safe solution is to acquire a press with a higher tonnage capacity appropriate for the task.

- If your primary focus is ensuring operational safety and longevity: Always operate within 80% of the press's rated tonnage for routine work, monitor the pressure gauge, and heed the sound of the relief valve as an absolute limit.

- If you have acquired a used press with an unknown history: Assume it may have been overloaded. Commission a professional inspection of the frame's welds and the cylinder's integrity before putting it into critical service.

Ultimately, a hydraulic press is a powerful tool that demands respect for its engineering limits.

Summary Table:

| Consequence of Overloading | Severity Level | Key Takeaway |

|---|---|---|

| Relief Valve Activation (Hissing Sound) | Warning | Machine is at its safe limit. Stop immediately. |

| Blown Seals & Fluid Leaks | Moderate | Causes downtime and requires repair. |

| Burst Hoses / Fluid Injection | Severe | Risk of severe personal injury or amputation. |

| Cylinder or Frame Failure | Catastrophic | Explosive, life-threatening event. |

Ensure your lab's safety and operational integrity. Overloading equipment is a preventable risk. KINTEK specializes in providing reliable, high-quality lab equipment, including hydraulic presses, designed to meet rigorous safety standards. Our experts can help you select the right equipment for your specific tonnage requirements and ensure it operates safely for years to come.

Don't compromise on safety. Contact our team today for a consultation on your laboratory equipment needs.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What role does a laboratory hydraulic press play in preparing solid model materials? Standardize for Precise Data.

- Why is a laboratory hydraulic press utilized for electrolyte pelletizing? Unlock High Ionic Conductivity

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data