Yes, a heat press is the definitive tool for transfers. In fact, its primary function is to apply various types of heat-activated designs onto substrates like apparel and other flat items. The machine is specifically engineered to provide the controlled heat and consistent pressure necessary for a professional and durable application.

A heat press is not just an option for transfers; it is the industry-standard equipment. Its ability to deliver precise temperature and even pressure across the entire design is what distinguishes a hobbyist result from a professional-grade product that can withstand repeated use and washing.

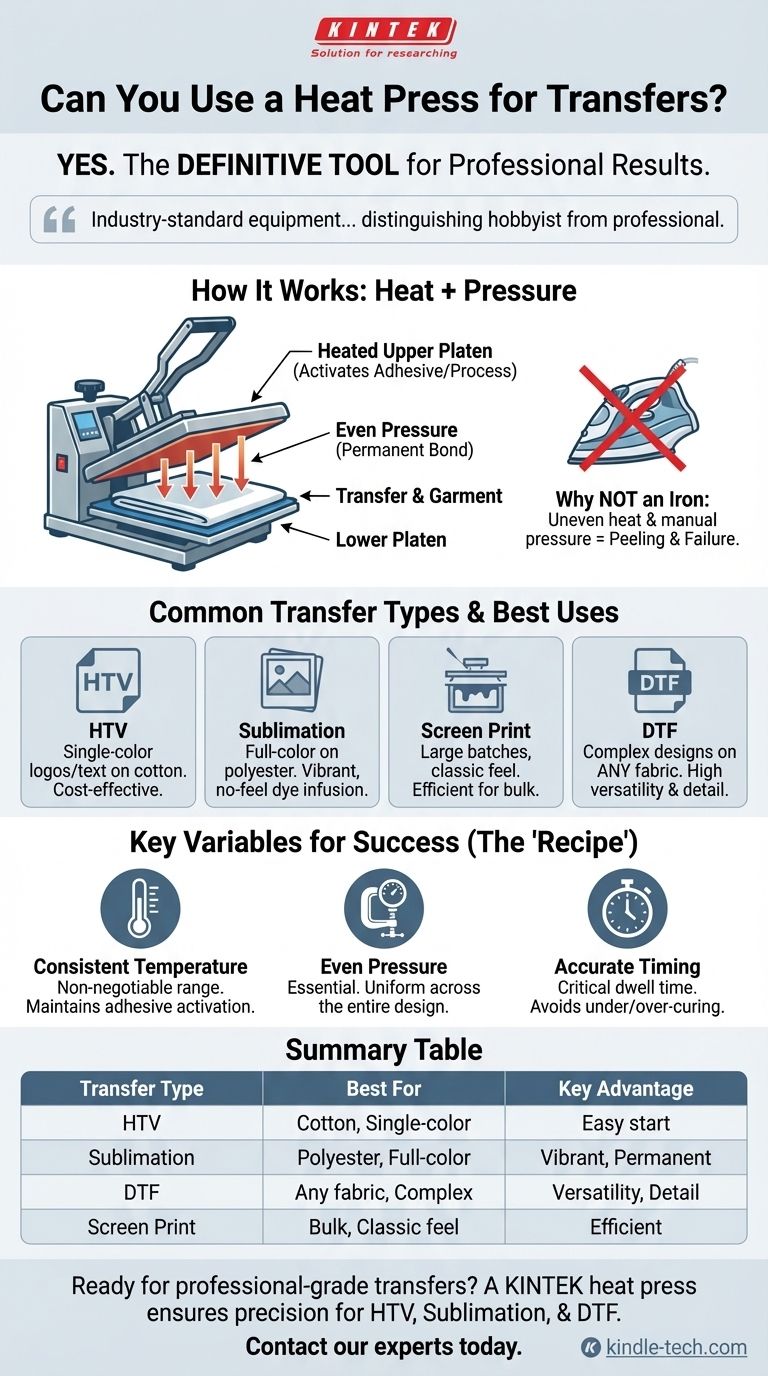

How a Heat Press Works with Transfers

A heat press might seem simple, but its design is critical for successfully applying transfers. It solves the core challenges of adhesion that other methods, like a home iron, cannot.

The Core Principle: Heat and Pressure

A heat press operates using a heated upper platen and a stationary lower platen. The transfer is placed on the garment, and the machine clamps down, applying both high heat and significant, even pressure for a set amount of time.

This combination is what activates the adhesive on the transfer (like in HTV or screen print transfers) or triggers a chemical process (like in sublimation), permanently bonding the design to the substrate's fibers.

Why an Iron Isn't a Substitute

While a home iron produces heat, it cannot deliver the consistent temperature or, more importantly, the even pressure required. Irons have hot and cool spots and rely on manual pressure, which inevitably leads to uneven application, peeling edges, and a design that fails quickly.

Common Types of Heat Transfers

The versatility of a heat press comes from the wide array of transfer technologies it supports. Each type has a unique application and result.

Heat Transfer Vinyl (HTV)

This is one of the most common methods. HTV is a sheet of vinyl material with a heat-activated adhesive on one side. The design is cut from the sheet, placed on the garment, and pressed, melting the adhesive and bonding the vinyl to the fabric.

Sublimation Transfers

Sublimation is a dye process, not a surface application. A design is printed on special paper with sublimation ink. When pressed at high heat, the ink turns into a gas and permanently infuses into the polyester fibers of the garment, resulting in a vibrant design with no feel or texture.

Screen Print Transfers

These transfers are created by screen printing a design with plastisol ink onto a special release paper. A heat press is then used to transfer the cured ink from the paper directly onto the garment, offering the look and feel of traditional screen printing without the complex setup for each item.

Direct-to-Film (DTF) Transfers

DTF involves printing a design onto a special film, which is then coated with an adhesive powder. The heat press is used to cure this adhesive and then transfer the entire ink and adhesive layer onto the garment. This method is highly versatile, working on cotton, polyester, and blends.

Other Specialized Applications

Beyond standard apparel transfers, a heat press is also used for applying white toner printer transfers, hotfix rhinestones, sequins, and other decorative elements that use a heat-activated glue.

Understanding the Trade-offs and Key Variables

Simply owning a heat press doesn't guarantee a perfect result. The success of any transfer is a precise recipe of three variables that you must control. Getting any one of them wrong will lead to failure.

Consistent Temperature is Non-Negotiable

Every transfer type has an ideal temperature range. Too low, and the transfer won't adhere properly. Too high, and you risk scorching the garment or melting the transfer itself. A quality heat press maintains a consistent temperature across the entire platen.

Even Pressure is Essential

This is the most common failure point for beginners. Insufficient or uneven pressure means parts of the design—especially the edges—won't bond to the fabric and will peel away after the first wash. The clamping mechanism of a press ensures uniform pressure that hand-application can never replicate.

Accurate Timing Matters

The duration of the press, or "dwell time," is the final critical factor. Too little time results in a weak bond. Too much time can damage the adhesive, the ink, or the fabric itself, often causing discoloration or a "shiny" box around the design.

Making the Right Choice for Your Goal

The best transfer method depends entirely on your project's materials and desired outcome.

- If your primary focus is single-color logos or text on cotton shirts: Heat Transfer Vinyl (HTV) is your most direct and cost-effective starting point.

- If your primary focus is full-color, photographic designs on polyester sportswear: Sublimation offers the most vibrant and durable results with zero surface texture.

- If your primary focus is complex, multi-color designs on any type of fabric: Direct-to-Film (DTF) transfers provide the greatest versatility and high-detail results.

- If your primary focus is producing large batches with a classic "screen printed" feel: Screen print transfers are an efficient and high-quality solution.

Ultimately, the heat press is the foundational tool that unlocks the potential of all these modern transfer technologies.

Summary Table:

| Transfer Type | Best For | Key Advantage |

|---|---|---|

| Heat Transfer Vinyl (HTV) | Single-color logos/text on cotton | Cost-effective, easy to start |

| Sublimation | Full-color photos on polyester | Vibrant, no-feel, permanent dye infusion |

| Direct-to-Film (DTF) | Complex designs on any fabric | High versatility and detail |

| Screen Print Transfers | Large batches, classic feel | Efficient for bulk orders |

Ready to achieve professional-grade transfers? A high-quality heat press from KINTEK ensures the precise temperature, even pressure, and accurate timing your projects demand. Whether you're working with HTV, sublimation, or DTF transfers, our lab-grade equipment delivers the consistency and durability needed for commercial success. Contact our experts today to find the perfect heat press for your specific transfer needs!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the hot pressing process polymer? Achieve Maximum Density and Strength for Critical Parts

- How does a precision hot press influence PEM electrolysis stack performance? Optimize Efficiency and Durability.

- What is the application of hot pressing? Achieve Maximum Density in Advanced Materials

- What is the function of a hot rolling press? Optimize Solid-State Electrolyte Performance & Density

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What is the core function of a laboratory heated hydraulic press in CSP? Optimize Solid-State Battery Densification

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- What environmental conditions does a laboratory hot press provide? Optimize Dry Electrode Densification