In short, yes, you can braze with MAPP Pro gas. Its flame temperature is high enough to melt common brazing filler alloys like silver-based rods. However, the critical factor is not just the flame's temperature, but its ability to transfer enough heat to bring the entire joint up to brazing temperature, which is highly dependent on the size and type of the metal you are working with.

The question isn't whether MAPP gas is hot enough to braze—it is. The real question is whether a simple air-fuel torch can deliver enough heat energy to overcome the heat sinking properties of your workpiece. For small jobs, it's effective; for large jobs, it will fail.

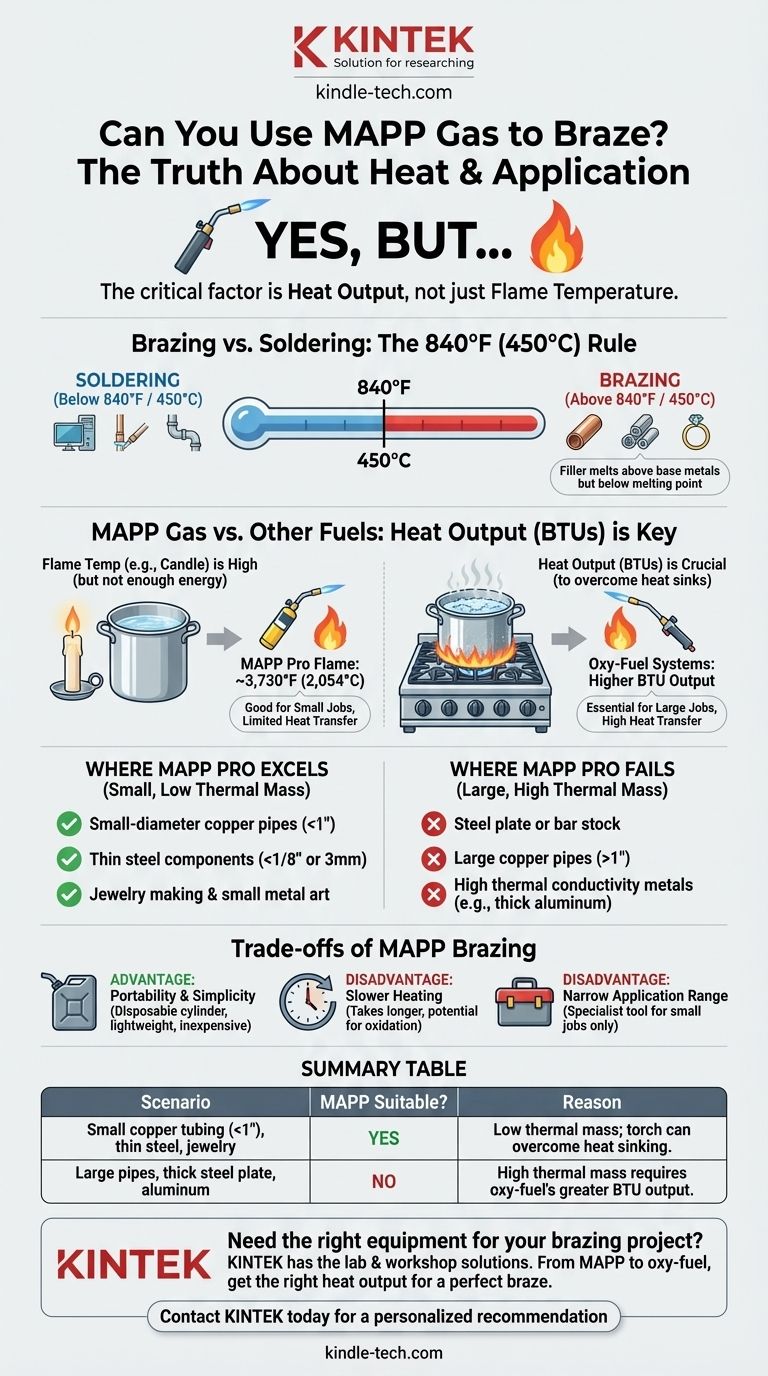

Brazing vs. Soldering: The Temperature Threshold

To understand the capability of MAPP gas, we must first be clear about the process. Brazing is often confused with soldering, but they are defined by a specific temperature.

The 840°F (450°C) Rule

Brazing is a metal-joining process that uses a filler metal that melts above 840°F (450°C) but below the melting point of the base metals. The filler is drawn into the joint by capillary action.

Soldering is a similar process but uses a filler metal that melts below 840°F (450°C). This is a much lower-strength bond typically used for electronics and some plumbing.

MAPP Gas vs. Other Fuels: A Matter of Heat

The success of a brazing operation hinges on the torch's ability to heat the base metal quickly and evenly. This involves two distinct concepts: flame temperature and heat output.

Flame Temperature is Only Half the Story

A typical MAPP Pro torch burning in air reaches a flame temperature of approximately 3,730°F (2,054°C). This is significantly hotter than propane (approx. 3,600°F) and well above the melting point of common silver brazing alloys, which are often in the 1,145°F to 1,650°F range.

The Real Limiting Factor: Heat Output (BTUs)

The true constraint is the rate of heat transfer (measured in BTUs/hour). Think of it like trying to boil a large stockpot of water with a single candle. The candle flame is very hot, but it simply cannot output enough energy to heat the entire volume of water.

A MAPP gas torch connected to the ambient air faces the same problem when heating large, thick pieces of metal. The metal acts as a heat sink, conducting heat away from the joint faster than the torch can supply it.

Where MAPP Pro Excels

A simple air-fuel MAPP Pro torch has sufficient heat output for jobs with low thermal mass, such as:

- Brazing small-diameter copper pipes (common in HVAC refrigerant lines).

- Joining thin steel components (less than 1/8" or 3mm thick).

- Jewelry making and small-scale metal art.

Where MAPP Pro Fails

You will struggle or fail to reach brazing temperature with a MAPP torch on larger jobs. The heat will dissipate too quickly. These applications require a more powerful oxy-fuel system (like oxy-acetylene):

- Brazing steel plate or bar stock.

- Joining large copper pipes (typically over 1-inch in diameter).

- Working with metals that have high thermal conductivity, like thick aluminum.

Understanding the Trade-offs of Using MAPP for Brazing

Choosing MAPP gas involves accepting a specific set of compromises compared to a professional oxy-acetylene rig.

Advantage: Portability and Simplicity

A MAPP torch setup consists of a single, disposable fuel cylinder and a torch head. It is lightweight, inexpensive, and readily available at any hardware store, making it ideal for a go-bag or occasional use.

Disadvantage: Slower Heating

Even on jobs where it works, MAPP gas will take significantly longer to bring the workpiece to temperature compared to an oxy-fuel flame. This increased time can lead to more heat spreading across the part and greater oxidation.

Disadvantage: Narrow Application Range

The primary trade-off is versatility. A MAPP torch is a specialist tool for small jobs. An oxy-acetylene system can handle almost any brazing or cutting task, from the most delicate to the very heavy.

Making the Right Choice for Your Brazing Project

Your choice of fuel should be dictated by the task at hand, not by the fuel itself.

- If your primary focus is small-diameter copper tubing (under 1"), jewelry, or thin sheet metal: MAPP Pro is an excellent, cost-effective, and convenient choice for achieving a successful braze.

- If your primary focus is joining steel thicker than 1/8", large pipes, or structural components: You require the superior heat output of an oxy-fuel system to get the job done correctly and efficiently.

- If your primary focus is maximum versatility for a wide range of future projects: Investing in an oxy-acetylene or oxy-propane setup is the professional standard for a reason.

Matching your fuel's heat capacity to the thermal demands of your workpiece is the fundamental principle of a successful braze.

Summary Table:

| Scenario | MAPP Gas Suitable? | Reason |

|---|---|---|

| Small copper tubing (<1"), thin steel, jewelry | Yes | Low thermal mass; torch can overcome heat sinking. |

| Large pipes, thick steel plate, aluminum | No | High thermal mass requires oxy-fuel's greater BTU output. |

Need the right equipment for your brazing project? Whether you're working on small, intricate joints or large, heavy-duty components, KINTEK has the lab and workshop equipment you need. Our experts can help you select the perfect torch system—from simple MAPP gas kits to professional oxy-fuel setups—ensuring you have the right heat output for a perfect braze every time.

Contact KINTEK today to discuss your specific application and get a personalized recommendation.

Visual Guide

Related Products

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Which critical experimental conditions does a high-pressure autoclave provide? Optimize Mixed Sulfide Leaching

- What environment does a PTFE-lined autoclave provide for TiO2-GQD synthesis? Achieve Superior Nanocomposite Results

- What is the function of high-pressure reactors in semiconductor catalyst preparation? Optimize Your Heterojunctions

- Why are stainless steel autoclaves key to PCL-TPE preparation? Mastering High-Vacuum Polycondensation

- How does a high-pressure hydrothermal autoclave facilitate the synthesis of BiVO4@PANI nanocomposites? Unlock Precision.