Yes, unequivocally. Carburization is a metallurgical heat treatment process specifically designed to increase the surface hardness of low-carbon steels. It achieves this by diffusing carbon into the surface, which allows that layer to form an extremely hard, wear-resistant structure after quenching, a result not possible with the original low-carbon base metal alone.

The true value of carburization is not just increasing hardness, but creating a dual-property component: an exceptionally hard, wear-resistant surface (the "case") fused to a tough, ductile, and impact-resistant interior (the "core").

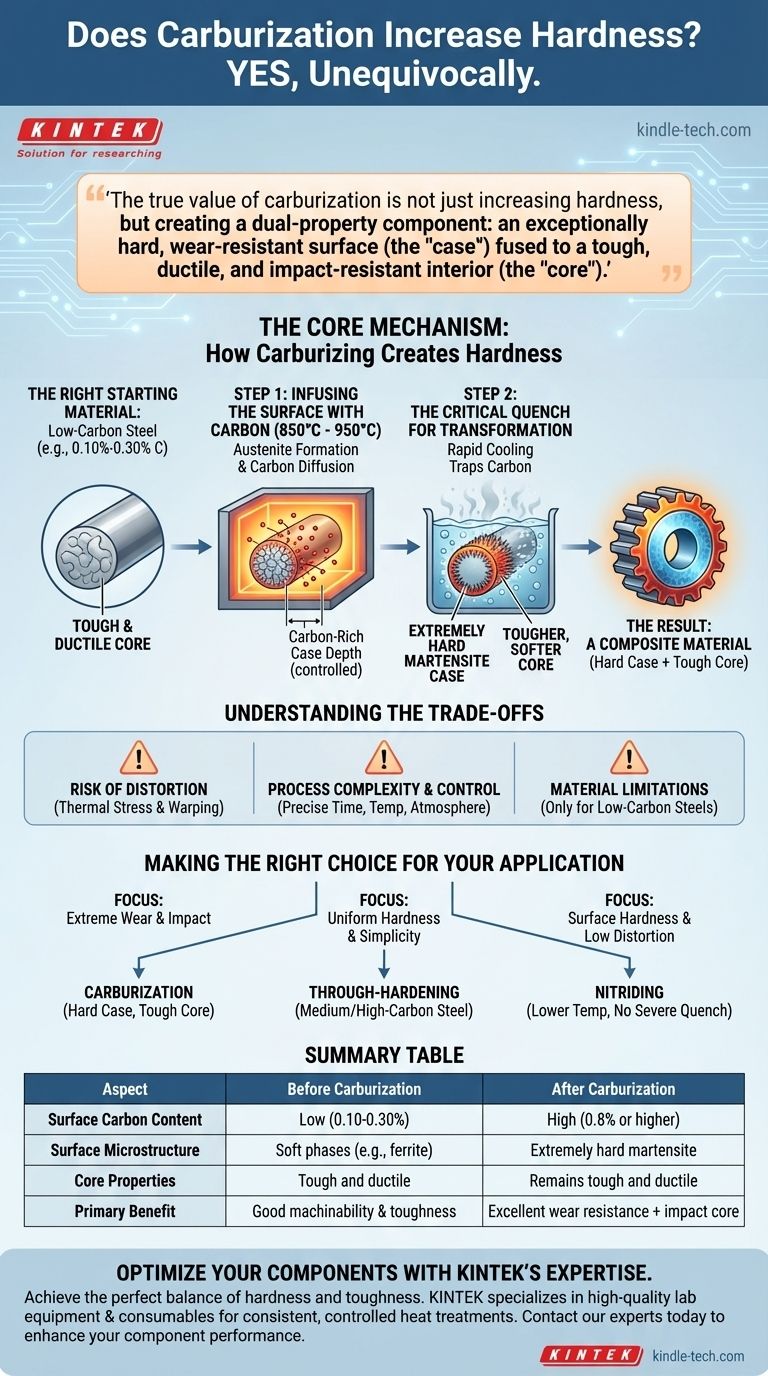

The Core Mechanism: How Carburizing Creates Hardness

To understand why carburization is so effective, you must see it not as a single step, but as a multi-stage transformation process. It fundamentally changes the chemistry and microstructure of the steel's surface.

The Right Starting Material: Low-Carbon Steel

Carburization is performed on steels with low carbon content, typically between 0.10% and 0.30% carbon (such as 1018 or 8620 steel).

These materials are inherently tough and easy to machine but cannot be significantly hardened by simple heating and quenching. They lack the necessary carbon to form the hard martensitic microstructure.

Step 1: Infusing the Surface with Carbon

The process begins by placing the steel component in a controlled, carbon-rich environment at a high temperature, usually between 850°C and 950°C (1560°F to 1740°F).

At this temperature, the steel's crystal structure changes to austenite, which has a high solubility for carbon. Carbon atoms from the surrounding atmosphere (gas, liquid, or solid compound) diffuse into the surface of the part.

The depth of this carbon-rich layer, known as the case depth, is precisely controlled by the temperature and the duration of the treatment.

Step 2: The Critical Quench for Transformation

After the surface has absorbed enough carbon (often reaching 0.8% or higher), the part is rapidly cooled, or quenched, in a medium like oil, water, or polymer.

This rapid cooling traps the carbon atoms and forces the high-carbon austenite at the surface to transform into martensite, an extremely hard, brittle, and wear-resistant microstructure. The low-carbon core, however, does not have enough carbon to form martensite and instead transforms into a much softer, tougher microstructure.

The Result: A Composite Material

The final carburized part is essentially a composite. It has a high-hardness case that can withstand abrasion and wear, and a soft, tough core that can absorb shock and impact without fracturing. This combination is ideal for components like gears, bearings, and camshafts.

Understanding the Trade-offs of Carburization

While highly effective, carburization is not without its challenges and limitations. A clear understanding of these trade-offs is crucial for successful application.

Risk of Distortion

The high temperatures and aggressive quenching involved in the process introduce significant thermal stress. This can cause the part to warp, twist, or change dimensions, which may require costly secondary operations like finish grinding to meet tight tolerances.

Process Complexity and Control

Achieving a consistent and correct case depth, carbon gradient, and final hardness requires precise control over time, temperature, and atmosphere composition. It is a more complex and time-consuming process than simpler methods like through-hardening.

Material Limitations

The process is only effective on low-carbon steels. Applying it to a medium or high-carbon steel is redundant and unnecessary, as those materials are already hardenable through a simpler quench-and-temper cycle.

Making the Right Choice for Your Application

Selecting the right hardening process depends entirely on the component's operational requirements.

- If your primary focus is extreme surface wear resistance combined with high impact strength: Carburization is the ideal choice for creating a hard case with a tough, ductile core.

- If your primary focus is uniform hardness throughout the component and process simplicity: Select a medium or high-carbon alloy steel and perform a standard through-hardening (quench and temper) treatment.

- If your primary focus is surface hardness with minimal part distortion: Consider a lower-temperature surface treatment like nitriding, which introduces nitrogen to create hardness without the need for a severe quench.

By matching the treatment process to the engineering need, you ensure the component achieves optimal performance and reliability.

Summary Table:

| Aspect | Before Carburization | After Carburization |

|---|---|---|

| Surface Carbon Content | Low (0.10-0.30%) | High (0.8% or higher) |

| Surface Microstructure | Soft phases (e.g., ferrite) | Extremely hard martensite |

| Core Properties | Tough and ductile | Remains tough and ductile |

| Primary Benefit | Good machinability and toughness | Excellent surface wear resistance with impact-absorbing core |

Optimize Your Components with KINTEK's Expertise

Does your application demand the perfect balance of a hard, wear-resistant surface and a tough, impact-resistant core? The carburization process is a precise science, and achieving optimal results requires the right equipment and consumables.

KINTEK specializes in supplying high-quality lab equipment and consumables for metallurgical processes. We help laboratories and manufacturers serving the automotive, aerospace, and heavy equipment industries ensure their heat treatments are consistent, controlled, and effective.

Let us help you enhance your component performance. Contact our experts today to discuss your specific needs and discover how KINTEK solutions can bring reliability and precision to your hardening processes.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost