Yes, induction heating is a highly effective and widely used method for heating and melting gold. The process is valued in metallurgical applications for its speed, efficiency, and the high degree of control it offers over the melting process, which helps preserve the quality of the metal.

Induction technology is a preferred industrial choice for processing gold, not just because it works, but because it excels at melting pure gold and creating alloys quickly and with minimal waste. Its primary limitation, however, is that it melts the metal without refining it.

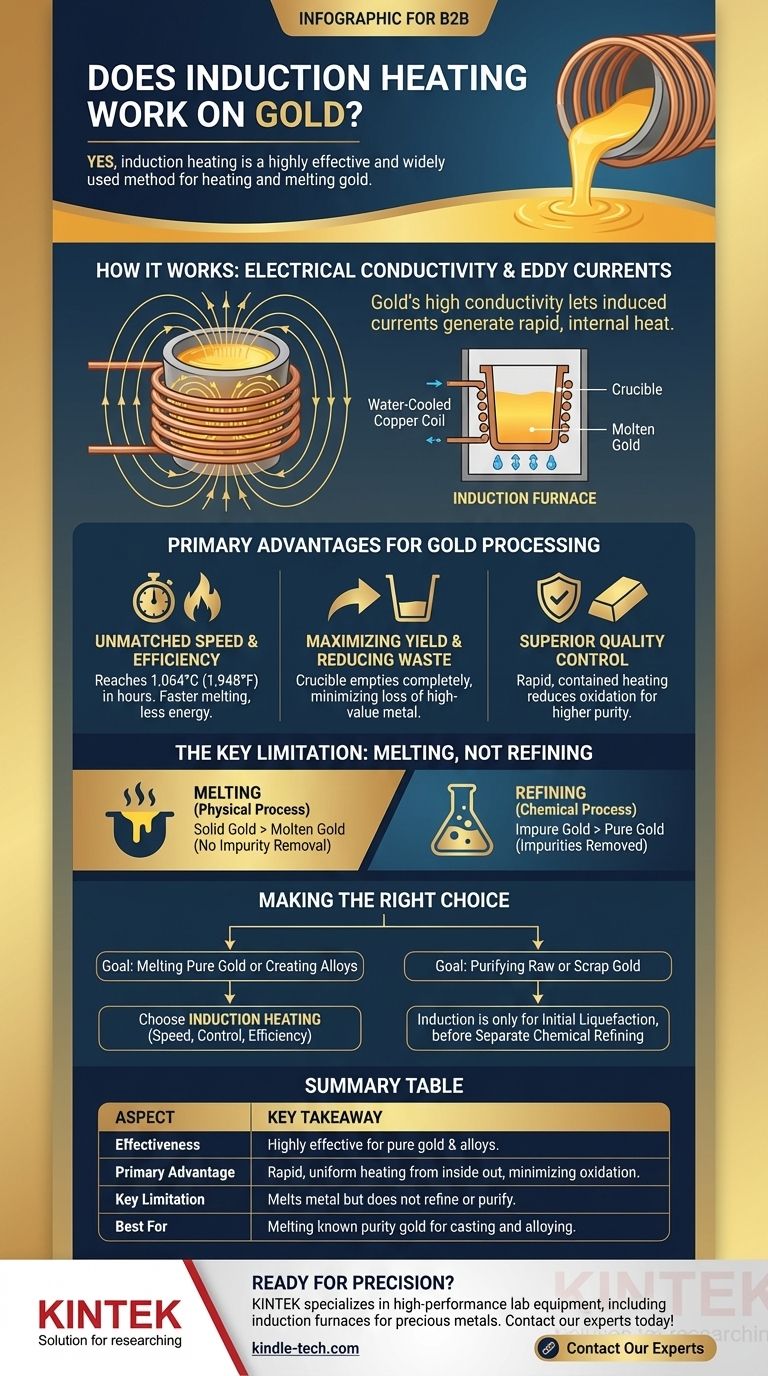

How Induction Heating Interacts with Gold

Induction heating is a non-contact process that uses electromagnetic fields to generate heat directly within a material. Its effectiveness with gold stems from the metal's inherent physical properties.

The Principle of Electrical Conductivity

Induction works by creating powerful, alternating magnetic fields around a crucible containing the gold. This field induces strong electrical currents, known as eddy currents, directly within the gold itself.

Because gold is an excellent electrical conductor, these currents flow easily, generating rapid and intense heat through electrical resistance. This allows the gold to melt from the inside out, offering uniform and efficient heating.

The Standard Equipment: Induction Furnaces

The process is typically carried out in an induction furnace. This equipment consists of a water-cooled copper coil that generates the magnetic field and a crucible (often made of graphite or ceramic) that holds the gold.

The design ensures that energy is transferred directly to the gold with very little waste, making it a highly energy-efficient method.

The Primary Advantages for Gold Processing

Using induction for gold smelting provides several distinct advantages over traditional methods, particularly in terms of speed, waste reduction, and final product quality.

Unmatched Speed and Efficiency

Induction furnaces can bring gold to its melting point of 1,064°C (1,948°F) in a matter of hours, a significant reduction compared to other furnace types. This accelerated melting process minimizes energy consumption and increases throughput.

Maximizing Yield and Reducing Waste

A key operational benefit is that induction furnaces can be completely emptied of their molten contents after a smelt. This feature is critical when working with a high-value material like gold, as it ensures minimal loss of metal between batches.

Superior Quality Control

The rapid and contained heating process reduces the opportunity for oxidation and contamination from atmospheric gases. This results in a higher quality and purity of the final molten gold, which is essential for alloying and casting applications.

Understanding the Key Limitation: No Refining

While induction heating is exceptional for melting, it is crucial to understand its primary trade-off: it does not refine the metal.

Melting vs. Refining

Melting is the process of changing a substance from a solid to a liquid state. Refining, on the other hand, is a chemical process that removes impurities to increase the grade or purity of the metal.

Induction heating is a physical process. It will efficiently melt everything in the crucible—gold and any other base metals mixed in—without separating them.

When Induction Is the Right Tool

Because it offers little to no refining capability, induction is best suited for melting gold of a known purity. It is ideal for applications like creating specific gold alloys (e.g., 14k or 18k gold) or for casting and forming pure gold into new shapes.

Making the Right Choice for Your Goal

Selecting the right heating method depends entirely on your starting material and your desired outcome.

- If your primary focus is melting pure gold or creating precise alloys: Induction heating is the superior choice for its speed, control, and efficiency.

- If your primary focus is purifying raw or scrap gold: Induction is only an initial step for liquefying the material before it undergoes separate chemical refining processes.

Ultimately, understanding this distinction is key to leveraging induction heating effectively in your work with precious metals.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Effectiveness | Highly effective for melting pure gold and creating alloys. |

| Primary Advantage | Rapid, uniform heating from the inside out, minimizing oxidation. |

| Key Limitation | Melts the metal but does not refine or purify it. |

| Best For | Melting gold of known purity for casting and alloying. |

Ready to enhance your gold processing with precision and efficiency?

KINTEK specializes in high-performance lab equipment, including induction furnaces ideal for melting gold and other precious metals. Our solutions deliver the speed, control, and minimal waste you need for superior results in alloy creation and casting.

Contact our experts today to find the perfect induction heating solution for your laboratory's specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- How does heat treatment process work? Tailor Material Properties for Your Application

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish