At its core, heat treatment is a highly controlled manufacturing process that uses specific cycles of heating and cooling to intentionally alter the physical, and sometimes chemical, properties of a material. By precisely managing temperature, time, and cooling rates, you can take a single metal alloy and transform its internal structure to make it harder, softer, or more durable, all without changing its fundamental shape.

The essential principle of heat treatment is not about changing what a material is made of, but rather rearranging its internal crystalline structure—its microstructure—to achieve specific, predictable mechanical properties like hardness, toughness, or ductility.

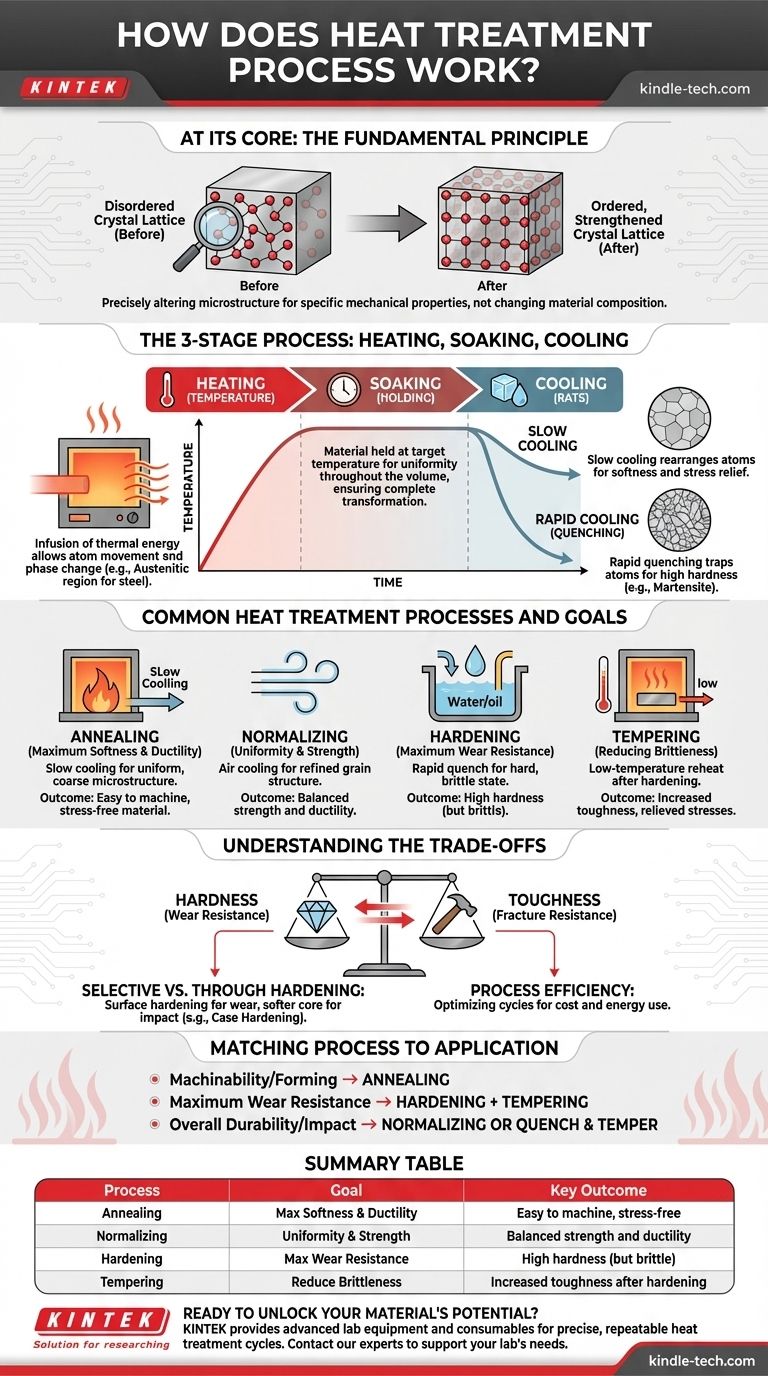

The Fundamental Principle: Changing the Microstructure

Heat treatment works by providing and then removing thermal energy to manipulate how atoms are arranged within a material. This process universally consists of three primary stages.

The Role of Temperature (Heating)

The first step is to heat the material to a specific, predetermined temperature. This infusion of thermal energy allows the atoms in the metal's crystal lattice to move more freely, enabling the internal structure to dissolve and transform into a different crystalline phase.

For carbon steel, this often means heating it into the austenitic region, a high-temperature state where the iron's structure can hold a significant amount of carbon in solution.

The Importance of Soaking (Holding)

Once the material reaches its target temperature, it is held there for a specific period. This "soaking" stage ensures that the structural transformation is complete and uniform throughout the entire volume of the part.

The duration of the soak depends on the material's thickness and composition. A thicker component requires a longer soak time to ensure the core reaches the same temperature and state as the surface.

The Power of Cooling Rate (Quenching)

This is the most critical stage, where the desired properties are "locked in." The rate at which the material is cooled from its high-temperature state dictates the final microstructure and, therefore, its mechanical properties.

A very slow cooling rate allows the atoms to rearrange back into a soft, stable, and stress-free structure. Conversely, a very rapid cooling—known as quenching—traps the atoms in a highly stressed, distorted, and extremely hard structure.

Common Heat Treatment Processes and Their Goals

Different combinations of heating, soaking, and cooling result in distinct processes, each designed to achieve a specific engineering outcome.

Annealing: For Maximum Softness and Ductility

Annealing involves heating a material and then cooling it very slowly, often by leaving it in the furnace to cool down over many hours. This process creates a uniform and coarse microstructure, resulting in a metal that is soft, ductile, and easy to machine or form. It is also used to relieve internal stresses created during previous manufacturing steps.

Normalizing: For Uniformity and Strength

Normalizing is similar to annealing but uses a faster cooling rate, typically by allowing the part to cool in still air. This produces a more refined and uniform grain structure, resulting in a material that has a better balance of strength and ductility compared to an annealed part.

Hardening: For Maximum Wear Resistance

Hardening is achieved by heating the material to its transformation temperature and then cooling it rapidly by quenching it in a medium like water, oil, or air. This rapid quench traps the microstructure in a very hard but brittle state, such as martensite in steel.

Tempering: For Reducing Brittleness

A part that has been hardened is often too brittle for most applications. Tempering is a secondary, low-temperature heat treatment performed after hardening. It slightly reduces hardness but significantly increases toughness, relieving the internal stresses created by quenching and preventing the part from being fragile.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it's a process of balancing competing properties. Understanding these trade-offs is crucial for successful application.

The Hardness vs. Toughness Balance

The most fundamental trade-off is between hardness (resistance to scratching and wear) and toughness (resistance to fracture from impact). A fully hardened material is extremely wear-resistant but can shatter like glass. Tempering is the act of consciously trading a small amount of hardness to gain a large amount of toughness.

Selective vs. Through Hardening

Not every part needs to have uniform properties. As the application dictates, you may only need a hard surface with a softer, tougher core. Processes like case hardening or induction hardening heat and quench only the surface, creating a part with high wear resistance on the outside and excellent impact resistance on the inside.

Process Efficiency and Cost

The choice of heat treatment directly impacts cost and production time. Longer, more complex cycles like slow annealing are more energy-intensive and expensive. Modern manufacturers focus on optimizing these cycles and utilizing waste heat to make the process more efficient without compromising the final properties of the part.

Matching the Process to Your Application

Your final choice depends entirely on the intended function of the component.

- If your primary focus is machinability or preparing a part for forming: Choose annealing to make the material as soft and stress-free as possible.

- If your primary focus is maximum wear resistance for a surface: Use a hardening process (like quenching or case hardening), followed by a low-temperature temper to relieve brittleness.

- If your primary focus is overall durability and impact resistance: Opt for normalizing or a carefully controlled quench-and-temper process designed to maximize toughness.

Ultimately, heat treatment empowers you to use a material's full potential by precisely tailoring its properties to the demands of its application.

Summary Table:

| Process | Goal | Key Outcome |

|---|---|---|

| Annealing | Maximum Softness & Ductility | Easy to machine, stress-free material |

| Normalizing | Uniformity & Strength | Balanced strength and ductility |

| Hardening | Maximum Wear Resistance | High hardness (but brittle) |

| Tempering | Reduce Brittleness | Increased toughness after hardening |

Ready to unlock the full potential of your materials? The precise heat treatment processes described are essential for achieving the exact hardness, toughness, and durability your components require. At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to execute these critical thermal cycles with accuracy and repeatability. Whether you are developing new alloys or optimizing production, our solutions help you achieve superior material properties. Contact our experts today to discuss how we can support your laboratory's specific heat treatment and material testing needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What problems can result from heat treating metal? Avoid Cracking, Warping, and Soft Spots

- What is the function of a vacuum reactor? Optimizing AISI 316L Surface Hardness via Ion Treatment

- How does a vacuum drying oven contribute to NCM622 pretreatment? Optimize Surface Quality for Li2ZrO3 Coating

- What does quenching do in heat treatment? Control Cooling Rates to Achieve Desired Material Properties

- How does a laboratory vacuum drying oven contribute to the pretreatment of Super C65? Ensure Battery Stability

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- Which furnace removes most air to prevent decarburization? The Definitive Guide to Vacuum Furnaces

- What is the critical point of heat treatment? Master the Key to Steel Transformation