In short, PECVD operates under vacuum conditions, typically in the low-pressure range, not at atmospheric pressure. The use of a vacuum is a defining characteristic of the process, enabling the creation of a plasma and ensuring the deposition of high-quality thin films at lower temperatures than other methods.

The decision to use a low-pressure vacuum in PECVD is not for cleanliness alone; it is a fundamental requirement to generate a stable plasma. This plasma provides the reaction energy, allowing high-quality film growth on substrates that cannot withstand high heat.

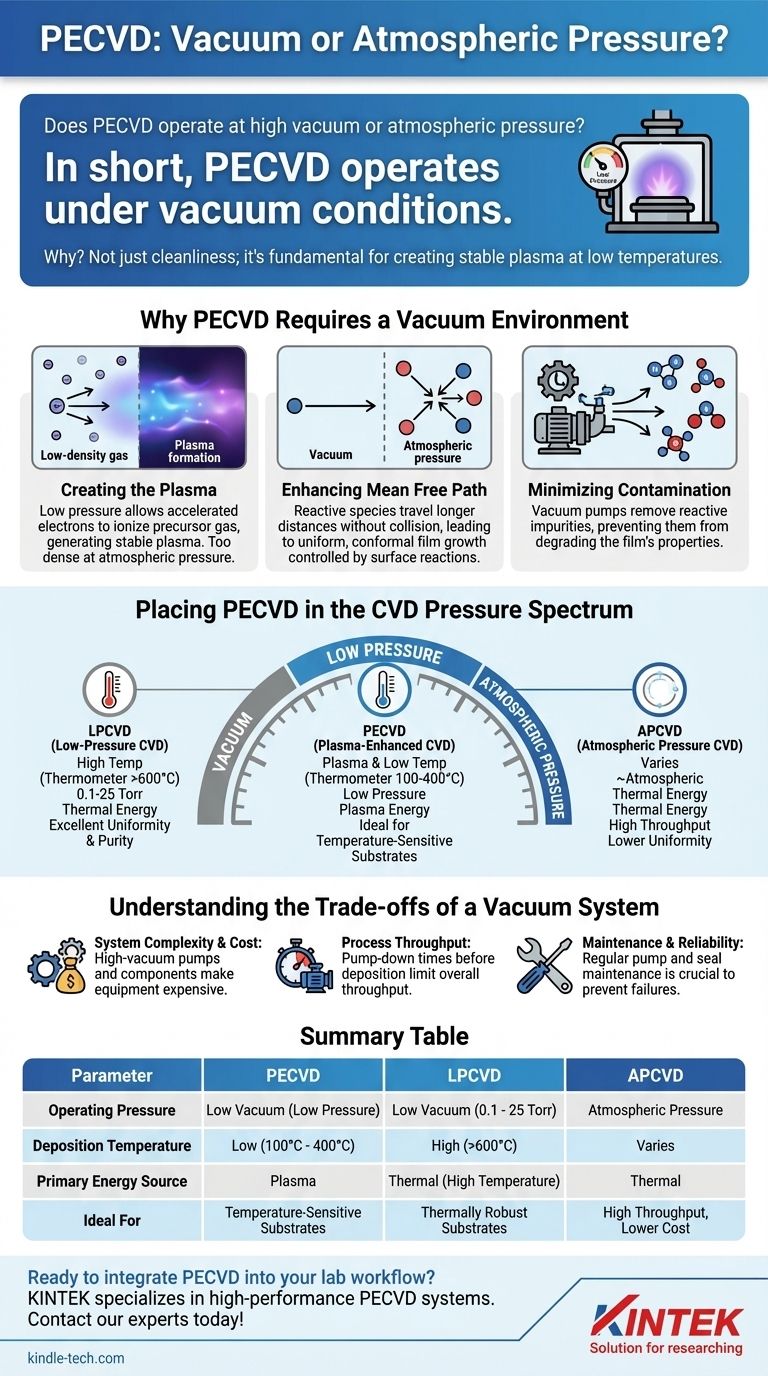

Why PECVD Requires a Vacuum Environment

The vacuum system is the heart of a PECVD tool. Its purpose extends far beyond simply removing air; it creates the precise physical conditions necessary for the process to work.

Creating the Plasma

A stable, uniform plasma can only be generated at low pressure. The vacuum reduces the density of gas molecules in the chamber.

This allows electrons, accelerated by the electric field, to gain enough energy to ionize the precursor gas molecules upon collision. At atmospheric pressure, the gas is too dense, and these collisions would happen too frequently, preventing the plasma from ever forming.

Enhancing Mean Free Path

Mean free path is the average distance a particle travels before colliding with another particle. In a low-pressure environment, this distance is significantly longer.

This allows the reactive chemical species created in the plasma to travel to the substrate surface with fewer gas-phase collisions. The result is a more uniform and conformal film, as the deposition is controlled by surface reactions, not by random encounters in the gas.

Minimizing Contamination

As the references note, vacuum systems use mechanical and molecular pumps to remove atmospheric gases like nitrogen, oxygen, and water vapor.

These ambient species are highly reactive and would otherwise be incorporated into the growing film as impurities. Such contamination can severely degrade the film's electrical, optical, and mechanical properties.

Placing PECVD in the CVD Pressure Spectrum

Chemical Vapor Deposition (CVD) is a family of processes, each optimized for different applications by controlling pressure and temperature. Understanding where PECVD fits provides critical context.

Atmospheric Pressure CVD (APCVD)

As the name implies, APCVD operates at or near standard atmospheric pressure. This makes the equipment simpler and allows for high throughput. However, the high pressure often leads to gas-phase reactions, which can create particles and result in lower-quality, less uniform films.

Low-Pressure CVD (LPCVD)

LPCVD operates in a vacuum, typically between 0.1 and 25 Torr. This low pressure improves film uniformity and purity compared to APCVD. However, LPCVD relies exclusively on high temperatures (often >600°C) to provide the energy needed to break down precursor gases and drive the surface reaction.

Plasma-Enhanced CVD (PECVD)

PECVD operates in a similar low-pressure range as LPCVD. The crucial difference is its use of plasma. The energy from the plasma, rather than thermal energy, drives the reaction.

This allows for significantly lower deposition temperatures (typically 100-400°C), making PECVD ideal for depositing films on substrates that cannot tolerate the high heat of LPCVD, such as plastics or fully processed silicon wafers with metal layers.

Understanding the Trade-offs of a Vacuum System

While essential, the use of a vacuum introduces specific engineering and process challenges.

System Complexity and Cost

Integrating high-vacuum systems, including expensive dry pumps and molecular pumps, along with associated gauges and valves, makes PECVD equipment significantly more complex and costly than atmospheric systems.

Process Throughput

Before each deposition, the chamber must be pumped down to the target pressure, a step that takes time. This pump-down cycle, along with chamber cleaning, can limit the overall wafer throughput compared to continuous or faster-cycling atmospheric processes.

Maintenance and Reliability

Vacuum components, particularly pumps and seals, require regular maintenance. They represent a common point of failure in semiconductor equipment, demanding a rigorous preventative maintenance schedule to ensure reliable operation.

Making the Right Choice for Your Goal

The choice between deposition techniques is always a function of your end goal. The operating pressure is a direct consequence of the balance you need to strike between film quality, temperature constraints, and cost.

- If your primary focus is high throughput and low cost: APCVD may be suitable for applications where film purity and uniformity are not the highest priority.

- If your primary focus is the highest film purity and uniformity on a thermally robust substrate: LPCVD is the classic choice, as its high-temperature process delivers excellent material properties.

- If your primary focus is depositing quality films on temperature-sensitive substrates: PECVD is the definitive solution, as its use of plasma within a vacuum enables low-temperature processing without sacrificing film quality.

Ultimately, understanding the role of pressure is fundamental to selecting the deposition technology that aligns with your specific material and device requirements.

Summary Table:

| Parameter | PECVD | LPCVD | APCVD |

|---|---|---|---|

| Operating Pressure | Low Vacuum (Low Pressure) | Low Vacuum (0.1 - 25 Torr) | Atmospheric Pressure |

| Deposition Temperature | Low (100°C - 400°C) | High (>600°C) | Varies |

| Primary Energy Source | Plasma | Thermal (High Temperature) | Thermal |

| Ideal For | Temperature-Sensitive Substrates | Thermally Robust Substrates | High Throughput, Lower Cost |

Ready to integrate PECVD into your lab workflow?

KINTEK specializes in providing high-performance PECVD systems and lab equipment tailored to your specific research and production needs. Our expertise ensures you achieve superior thin film quality on temperature-sensitive substrates, enhancing your device performance and accelerating your time-to-market.

Contact our experts today to discuss how our PECVD solutions can advance your laboratory capabilities!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- How hard is DLC coating? Achieve Superior Wear Resistance with Hardness Up to 90 GPa

- What are the advantages of using a PECVD system for DLC films? Achieve Low-Temp Precision for Sensitive Substrates

- How does PECVD equipment facilitate SiC deposition on sensitive substrates? Unlock Low-Temp Thin Film Solutions

- What is PECVD cluster tool deposition used for? Essential for High-Purity Multi-Layer Device Fabrication

- What is the function of MW PECVD in boron-doped diamond synthesis? Master Molecular Tuning & Conductivity

- What role does a stainless steel bubbler play in RF-PECVD? Enhance Precursor Delivery for Siloxane Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is the temperature of PECVD oxide? Achieve Low-Temperature Deposition for Sensitive Materials