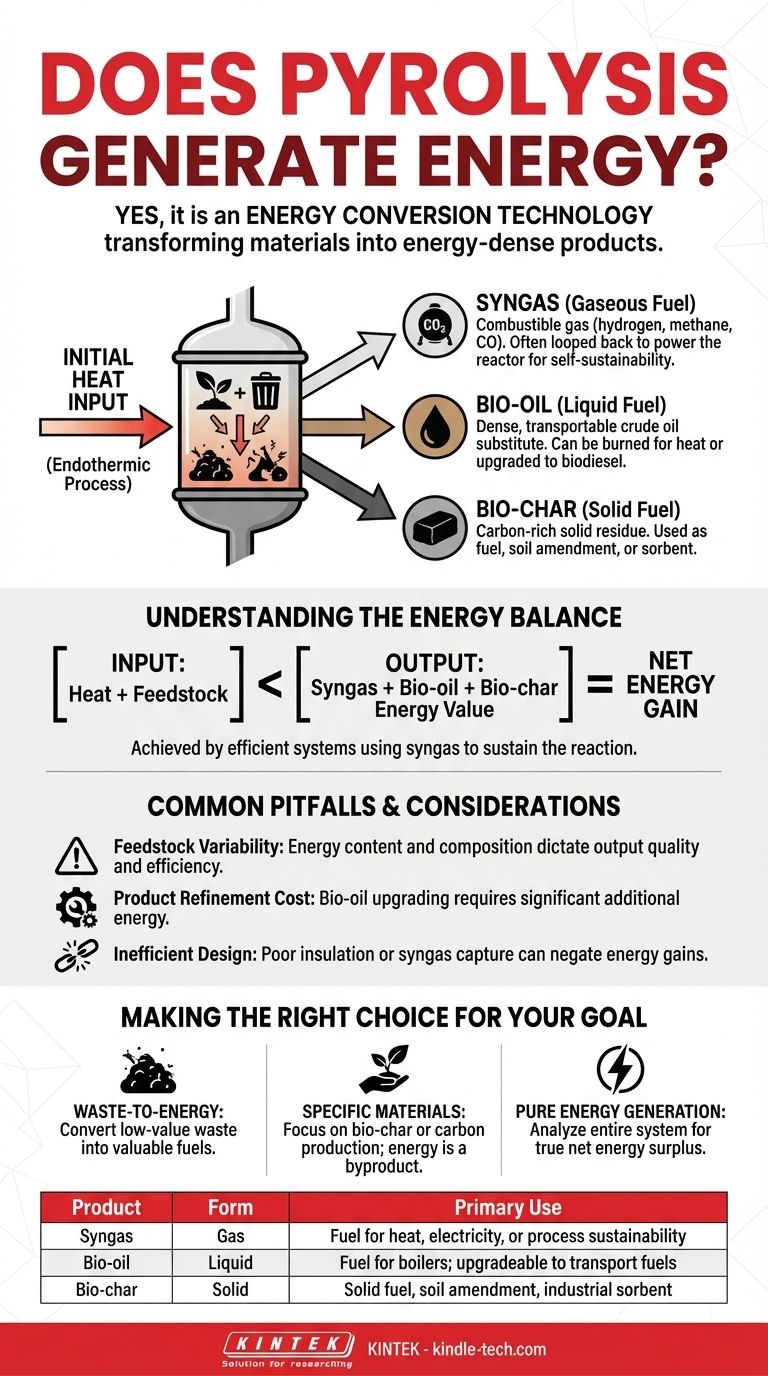

Yes, pyrolysis is fundamentally an energy-generating process, though it's more accurate to call it an energy conversion technology. It requires an initial input of heat to start, but it transforms materials like biomass or waste into a suite of energy-dense products: combustible gas, liquid bio-oil, and solid bio-char.

Pyrolysis does not create energy from nothing. Instead, it unlocks the stored chemical energy within a feedstock, converting it into more useful and versatile forms of fuel. The net energy gain depends entirely on the efficiency of the system and the value derived from its outputs.

How Pyrolysis Unlocks Chemical Energy

Pyrolysis is the process of thermal decomposition at high temperatures in an oxygen-free environment. By heating a material without allowing it to burn, you break down complex molecules into simpler, more stable, and often energy-rich components.

The Gaseous Fuel: Syngas

The process creates non-condensable gases, often called syngas or pyrolysis gas. This gas is a mixture of combustible components like hydrogen, methane, and carbon monoxide.

In many modern pyrolysis plants, this gas is immediately looped back to provide the heat needed to sustain the reaction. This creates a self-sustaining system that significantly improves the overall energy balance.

The Liquid Fuel: Bio-oil

Pyrolysis also produces a liquid known as pyrolysis oil or bio-oil. This is a dense, dark liquid that can be considered a type of crude oil derived from biomass or waste.

This bio-oil is a transportable and storable fuel. It can be burned in furnaces or boilers for heat or upgraded through further refining into transportation fuels like biodiesel.

The Solid Fuel: Bio-char

The solid residue left after pyrolysis is bio-char or coke. This charcoal-like material retains a significant amount of carbon and, therefore, chemical energy.

Bio-char can be burned as a solid fuel, often in the form of briquettes. It also has valuable non-energy applications, such as a soil amendment in agriculture or as an industrial sorbent.

Understanding the Energy Balance: Input vs. Output

The most critical concept to grasp is that pyrolysis is an endothermic process, meaning it requires an initial and sustained input of thermal energy to work. Whether the overall process is a net energy producer depends on a simple equation.

The Initial Energy Requirement

Heat is the primary energy cost of pyrolysis. A reactor must be heated to the target temperature (typically 400-800°C) and kept there. This initial investment is the main energy "debt" the process must overcome.

Achieving a Positive Net Energy Gain

A pyrolysis system becomes a net energy producer when the energy value of its outputs (gas, oil, and char) is greater than the energy required to run the process.

Highly efficient systems achieve this by using the produced syngas to power the reactor. Once the process is self-sustaining, all the bio-oil and bio-char produced—plus any excess syngas—represent a net energy gain.

Common Pitfalls and Considerations

While pyrolysis holds great potential, its effectiveness is not guaranteed. Several factors can turn a promising energy-producing system into an energy sink.

Feedstock Variability is Critical

The energy content and composition of the input material (feedstock) directly dictate the output. Dry wood chips will yield a very different energy profile than wet agricultural waste or plastic. Inconsistent or low-quality feedstock can cripple a system's efficiency.

Product Refinement Has an Energy Cost

Bio-oil is not a drop-in replacement for diesel fuel. It is often acidic, corrosive, and unstable, requiring significant energy-intensive upgrading before it can be used in standard engines. This secondary energy cost is often overlooked in simple calculations.

Inefficient Design Can Negate Gains

A poorly insulated reactor or an inefficient system for capturing and using the syngas can easily consume more energy than the value of the fuel it produces. The engineering and design of the pyrolysis unit are paramount to its success as an energy generator.

Making the Right Choice for Your Goal

Whether pyrolysis is the right technology depends entirely on your objective.

- If your primary focus is waste-to-energy: Pyrolysis is an excellent method for converting low-value waste streams into valuable, storable fuels, effectively recovering energy that would otherwise be lost in a landfill.

- If your primary focus is creating specific materials: Your goal might be producing high-quality bio-char for agriculture or solid carbon from methane pyrolysis; in this case, the energy generated is a valuable byproduct, not the main driver.

- If your primary focus is pure energy generation: You must analyze the entire system—from feedstock logistics to product refinement—to ensure the process provides a true net energy surplus for your specific application.

Ultimately, pyrolysis is a powerful technology for energy conversion and resource recovery, transforming challenging materials into valuable fuel sources.

Summary Table:

| Pyrolysis Product | Form | Primary Use |

|---|---|---|

| Syngas | Gas | Fuel for heat, electricity, or to sustain the pyrolysis process |

| Bio-oil | Liquid | Fuel for boilers; can be upgraded to transportation fuels |

| Bio-char | Solid | Solid fuel, soil amendment, or industrial sorbent |

Ready to harness the power of pyrolysis for your lab or facility? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis systems designed for efficient energy conversion and material recovery. Whether you're researching waste-to-energy solutions or scaling up production, our expertise ensures you get reliable, precise results. Contact us today to discuss how our solutions can optimize your energy recovery processes and meet your specific laboratory needs.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results