Yes, hydraulic presses can and do fail. Like any piece of high-performance machinery, they are subject to the laws of physics, material science, and wear and tear. Failures can range from slow, manageable fluid leaks to sudden, catastrophic structural collapses that release enormous amounts of stored energy.

The core issue is not whether a press can fail, but understanding the two distinct ways it fails. Failure is almost always a result of a breakdown in either the hydraulic fluid system that generates the force or the physical structure that contains it. Recognizing the difference is the key to safety and reliability.

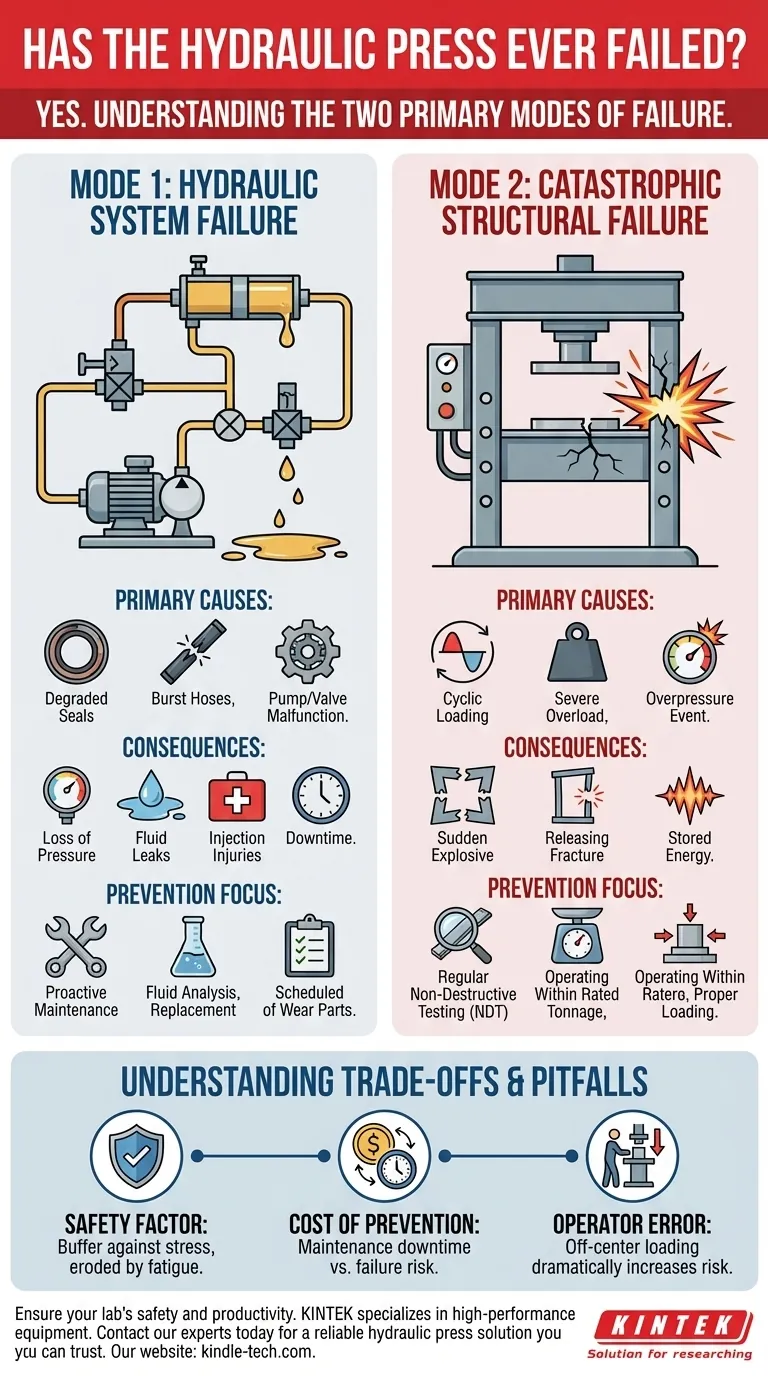

Deconstructing Failure: The Two Primary Modes

A hydraulic press is a system of systems. Thinking of failure as a single event is a mistake; it's a chain reaction that begins at a specific point of weakness.

Mode 1: Hydraulic System Failure

This is the most common category of failure. It involves the components that manage and transmit the hydraulic fluid, which is the lifeblood of the press. These failures typically result in a loss of pressure and function.

The most frequent culprits are seals and gaskets. These rubber or polymer components prevent fluid from leaking past pistons and connections. Over time, they degrade from heat, pressure, and chemical exposure, leading to leaks, pressure loss, and reduced performance.

Hoses and lines can also rupture. A sudden hose burst releases a high-velocity jet of hydraulic fluid that can cause severe injection injuries and represents a sudden, uncontrolled loss of all pressure in that circuit.

Finally, the pump or control valves can malfunction. A failing pump, the "heart" of the system, cannot generate the required pressure. A stuck valve, the "brain," can prevent the press from moving, retracting, or holding its force correctly.

Mode 2: Catastrophic Structural Failure

This type of failure is far less common but infinitely more dangerous. It involves a fracture of the main load-bearing components of the press, such as the frame, cylinder body, or platens (the flat pressing surfaces).

The primary cause is metal fatigue. Each time the press is used, its steel frame flexes on a microscopic level. Over millions of cycles, this cyclic loading can initiate and propagate microscopic cracks, especially in areas of high stress concentration like sharp corners or welds.

If a crack grows large enough, the frame can no longer withstand the operational forces, leading to a sudden, explosive fracture. This is a complete and instantaneous release of all the energy stored in the compressed structure.

Another cause is a severe overload or overpressure event. If an operator attempts to press something that requires more force than the press's rated tonnage, or if the hydraulic pressure relief valve fails, the stress on the frame can exceed its ultimate tensile strength, causing it to break.

Understanding the Trade-offs and Pitfalls

Building and operating a perfectly failure-proof machine is impossible. The design and use of a hydraulic press involves balancing performance, cost, and safety.

The Role of the Safety Factor

Engineers design a press frame to withstand forces significantly higher than its official tonnage rating. This "safety factor" provides a buffer against unforeseen stress, material imperfections, and minor overloads. However, this buffer is not infinite and can be eroded by fatigue over the machine's life.

The Cost of Prevention

The most effective way to prevent failure is through rigorous maintenance and inspection. This includes regularly analyzing hydraulic fluid, replacing hoses on a schedule, and using techniques like ultrasonic or magnetic particle testing to check for cracks in the frame. This creates a trade-off between the cost and downtime of maintenance versus the risk of a failure.

Operator Error: The Human Element

A perfectly designed and maintained press can still fail if used improperly. Off-center loading is a major pitfall, where the workpiece is not placed in the center of the platen. This creates immense bending forces on the ram and frame that they were not designed to handle, dramatically increasing the risk of both hydraulic and structural failure.

How to Prevent Failure in Your Application

Preventing failure is about respecting the immense energy the machine controls. Your focus will depend on your primary objective.

- If your primary focus is operational safety: Non-destructive testing (NDT) of welds and critical frame components on a regular schedule is the only way to catch fatigue cracks before they become catastrophic.

- If your primary focus is machine longevity: Adhere strictly to the manufacturer's maintenance schedule for hydraulic fluid and filters, and operate the press consistently within, not at, its maximum tonnage rating.

- If your primary focus is avoiding downtime: Proactively replace wear items like seals and hoses before they fail, as a slow leak today can become a complete shutdown tomorrow.

Understanding these failure points transforms you from a simple operator into a steward of a powerful tool, ensuring it performs safely and effectively for its entire service life.

Summary Table:

| Failure Mode | Primary Cause | Consequence | Prevention Focus |

|---|---|---|---|

| Hydraulic System Failure | Degraded seals, burst hoses, pump/valve malfunction | Loss of pressure, fluid leaks, injection injuries, downtime | Proactive maintenance, fluid analysis, scheduled replacement of wear parts |

| Catastrophic Structural Failure | Metal fatigue, severe overload, overpressure event | Sudden, explosive fracture releasing stored energy | Regular non-destructive testing (NDT), operating within rated tonnage, proper loading |

Ensure your lab's safety and productivity. A reliable hydraulic press is critical for your operations. KINTEK specializes in high-performance lab equipment, including hydraulic presses, and provides the expertise and support to help you choose the right machine and maintain it for maximum safety and longevity.

Contact our experts today to discuss your specific laboratory needs and find a hydraulic press solution you can trust.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis