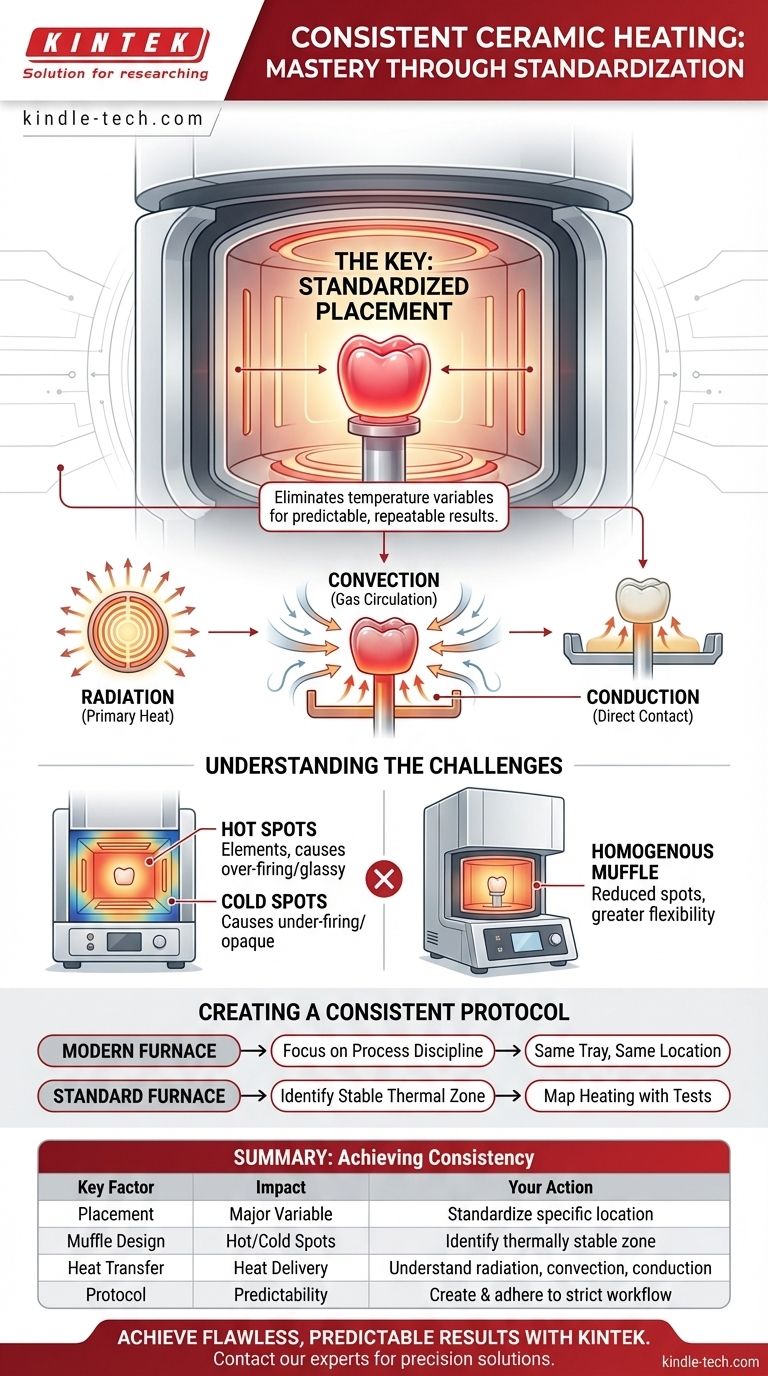

The single most effective way to achieve consistent heating is to establish and strictly adhere to a specific, designated placement for every ceramic restoration within your firing chamber. This simple discipline removes a critical variable from the firing process, directly leading to more predictable and repeatable results.

Inconsistent firing outcomes are almost always caused by temperature variations—hot and cold spots—within the furnace muffle. Mastering consistency is not about finding a magic setting, but about understanding your specific furnace's heat dynamics and creating a standardized, repeatable workflow.

The Core Principle: Process Standardization

The foundation of any high-quality laboratory process is the elimination of variables. When it comes to firing ceramics, the position of the restoration inside the furnace is a major variable that is entirely within your control.

Why Location is Critical

Even high-quality furnaces can have minor temperature gradients across the firing chamber. Placing a restoration in the center for one cycle and near the edge for another will expose them to different thermal conditions, leading to inconsistent maturation, shade, and fit.

By always using the same location, you ensure that every restoration experiences an identical heating and cooling cycle, making your results highly predictable.

The Role of Modern Furnace Design

Some modern furnaces are engineered with advanced muffles designed to create a homogenous temperature profile. This technology significantly reduces or eliminates the presence of hot or cold spots.

In these furnaces, the exact placement becomes less critical. A restoration placed on a firing pin can be expected to reach the same level of maturity as one placed on a firing pillow, offering greater flexibility. However, maintaining a consistent placement is still best practice.

Understanding Heat Transfer in Your Furnace

To truly control the process, you must understand how heat reaches the restoration. Heat is transferred in three primary ways, and each plays a role inside the furnace chamber.

Radiation

This is the primary method of heating. The furnace's heating elements (coils) radiate thermal energy, which travels through the space in the muffle and is absorbed by the restoration and firing tray.

Convection

As the air or gas inside the chamber heats up, it circulates. This flow of hot gas, or convection, helps to distribute heat throughout the muffle, carrying energy to all surfaces of the restoration.

Conduction

Conduction is heat transfer through direct contact. Heat conducts from the furnace walls to the firing tray, and from the tray or firing pin directly into the base of the ceramic restoration.

Common Pitfalls and Solutions

Understanding the principles of heat transfer helps diagnose and solve common issues that lead to inconsistent results.

The Problem of "Hot Spots"

In many furnaces, areas closer to the heating elements receive more direct radiant heat, creating "hot spots." Restorations placed here can easily be over-fired, resulting in a glassy, translucent appearance.

Identifying "Cold Spots"

Conversely, areas further from the elements or in corners with poor convection flow can be cooler. Placing restorations in these "cold spots" can lead to under-firing, resulting in a weak, opaque ceramic.

Advanced Temperature Management

For certain types of tube furnaces, inconsistencies can be actively managed. Placing a metal tubular insert inside the primary tube can help to even out the temperature profile and achieve more uniform heating across the entire zone.

Creating a Consistent Firing Protocol

Your goal is to develop a protocol that delivers predictable quality every time. Your strategy will depend on the equipment you use.

- If you use a modern furnace with a homogenous muffle: Your focus should be on perfect process discipline. While placement is more forgiving, using the same tray and general location removes any remaining variables.

- If you use a standard or older furnace: Your primary task is to identify the most stable thermal zone in your muffle and commit to using it exclusively.

- If you are troubleshooting inconsistent results: Systematically test different locations in your furnace with identical restorations to "map" its heating characteristics and find the optimal placement.

By taking control of these variables, you transform the firing process from an art into a science.

Summary Table:

| Key Factor | Impact on Consistency | Your Action |

|---|---|---|

| Restoration Placement | Major variable; causes inconsistent results. | Standardize one specific location in the muffle. |

| Furnace Muffle Design | Determines the presence of hot/cold spots. | Identify the most thermally stable zone in your furnace. |

| Heat Transfer Methods | Affects how heat reaches the restoration. | Understand radiation, convection, and conduction in your process. |

| Process Protocol | Turns firing from an art into a repeatable science. | Create and adhere to a strict, documented firing workflow. |

Achieve Flawless, Predictable Ceramic Firing Results with KINTEK

Struggling with inconsistent shades or ceramic maturity? The root cause often lies in your furnace's temperature profile. At KINTEK, we specialize in laboratory equipment solutions that bring precision and reliability to your workflow.

We provide the tools and expertise to help you:

- Standardize your process with furnaces designed for homogenous heating.

- Eliminate variables that lead to costly remakes and wasted time.

- Achieve predictable, high-quality results for every single restoration.

Ready to transform your ceramic firing from an art into a precise science?

Contact our dental lab experts today to discuss your specific challenges and discover how KINTEK's solutions can enhance your laboratory's consistency and profitability.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the strength of dental porcelain? A Guide to Durability and Aesthetics

- What are the different types of dental furnaces? Choose the Right Furnace for Your Dental Lab

- What are the components of dental porcelain? A Guide to Engineered Strength and Beauty

- What factors are important to consider when choosing a dental sintering furnace? Match Your Workflow for Optimal Results

- What is a dental porcelain furnace? The Key to In-House, High-Quality Dental Restorations

- How strong are ceramic implants? Discover the Power of Zirconia for a Metal-Free Smile

- What is the temperature of a dental furnace? Mastering Heat for Perfect Zirconia Sintering

- What is dental ceramic made of? Discover the Science Behind Strong, Beautiful Teeth