Calculating filter press capacity is not done with a simple, universal formula. It is determined experimentally through a pilot-scale or bench-scale test that simulates the full-scale process. This test measures the specific filtration characteristics of your slurry, such as cake formation rate, final cake solids, and cycle time, which are then used to accurately calculate the capacity for a production-sized press.

The "capacity" of a filter press is not an inherent property of the machine alone; it is a dynamic result of the interaction between the press, the filter media, and your specific slurry. Therefore, a controlled test is the only reliable method to gather the data needed for an accurate calculation.

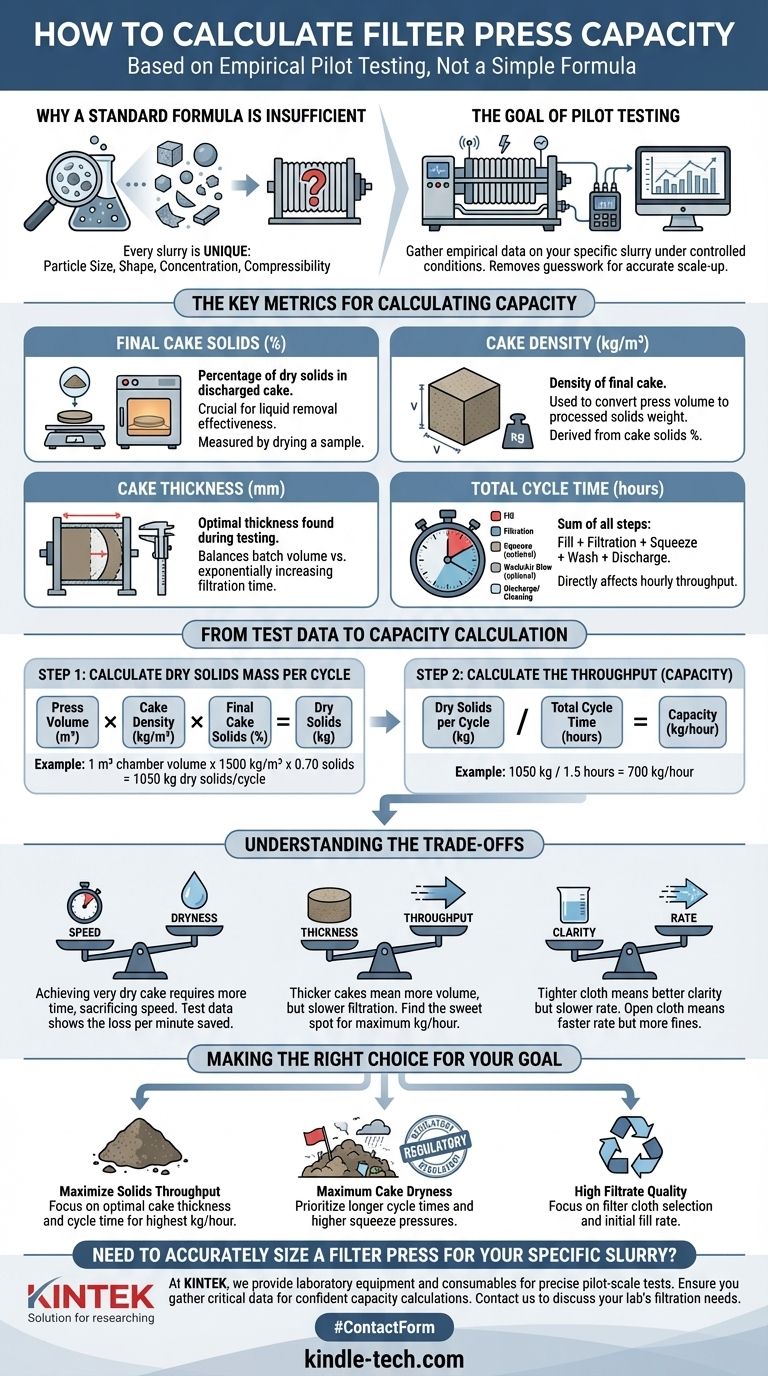

Why a Standard Formula is Insufficient

Every industrial slurry is unique. Its behavior during dewatering is governed by factors that cannot be easily predicted without testing.

The Uniqueness of Your Slurry

Slurry characteristics like particle size distribution, shape, concentration, and compressibility have a dramatic impact on how quickly it dewaters. A fine, slimy sludge will behave very differently from a coarse, crystalline material.

The Goal of Pilot Testing

A pilot test, as described in standard industry procedures, is designed to gather empirical data on your specific slurry under controlled conditions. This data removes the guesswork from scaling up and provides the core metrics needed for the capacity calculation.

The Key Metrics for Calculating Capacity

The pilot test is designed to measure several critical variables. These variables become the inputs for your capacity calculation.

Final Cake Solids (%)

A primary goal of filtration is to remove liquid, so the final percentage of dry solids in the discharged filter cake is a crucial performance metric. This is measured by taking a sample of the final cake, weighing it, drying it in an oven, and weighing it again.

Cake Density (kg/m³)

The density of the final cake is required to convert the volume of the press into a weight of processed solids. It is derived from the cake solids percentage and the specific gravity of the solids.

Cake Thickness (mm)

During the test, you establish an optimal cake thickness. Thicker cakes mean more solids per batch, but the filtration time increases exponentially as the cake gets thicker. The test helps find the sweet spot that maximizes overall throughput.

Total Cycle Time (minutes or hours)

This is the total time required to complete one full filtration batch. It is the sum of several distinct steps:

- Fill Time: The time it takes to pump slurry into the press chambers.

- Filtration Time: The time spent under pressure until the filtrate flow slows to a minimum.

- Squeeze Time (for membrane presses): The time for the membrane to squeeze the cake and remove more liquid.

- Cake Wash/Air Blow (optional): Time for any additional cake processing steps.

- Discharge/Cleaning Time: The mechanical time it takes to open the press, discharge the cakes, and close it for the next cycle.

From Test Data to Capacity Calculation

Once you have gathered the metrics from your pilot test, you can calculate the expected production capacity.

Step 1: Calculate Dry Solids Mass Per Cycle

First, determine the mass of dry solids you can produce in a single batch with a given press volume. This is the most important output of the process.

The formula is:

Dry Solids (kg) = Press Volume (m³) × Cake Density (kg/m³) × Final Cake Solids (%)

For example, a press with a 1 m³ chamber volume producing a cake with a density of 1,500 kg/m³ and 70% solids would yield 1,050 kg of dry solids per cycle (1 × 1500 × 0.70).

Step 2: Calculate the Throughput (Capacity)

Next, divide the mass of dry solids per cycle by the total cycle time. This gives you the capacity, typically expressed in kg per hour.

The formula is:

Capacity (kg/hour) = Dry Solids per Cycle (kg) / Total Cycle Time (hours)

If the 1,050 kg cycle from the example above took 1.5 hours, the capacity would be 700 kg/hour (1050 / 1.5).

Understanding the Trade-offs

Optimizing a filter press is always a game of trade-offs. The pilot test helps you make informed decisions about these compromises.

Speed vs. Dryness

Achieving a very dry cake requires more time under pressure (either longer filtration or a longer membrane squeeze). If you prioritize speed (shorter cycle time), you will almost always sacrifice some cake dryness. The test data will show you exactly how much dryness you lose for every minute you save.

Cake Thickness vs. Throughput

While a thicker cake processes more volume per batch, it can dramatically slow the filtration rate. There is an optimal cake thickness that maximizes the overall kg/hour throughput. Testing different thicknesses is key to finding this optimum point for your slurry.

Filtrate Clarity vs. Rate

Using a tighter filter cloth to achieve higher filtrate clarity can slow down the filtration rate, reducing overall capacity. Conversely, a more open cloth may increase speed but let more fine solids pass into the filtrate.

Making the Right Choice for Your Goal

Use the data from your pilot test to size a filter press that is aligned with your specific operational priority.

- If your primary focus is maximizing solids throughput (e.g., for bulk dewatering): Concentrate on finding the optimal balance between cake thickness and cycle time to achieve the highest kg/hour rating.

- If your primary focus is achieving maximum cake dryness (e.g., for meeting landfill regulations): Prioritize longer cycle times and higher squeeze pressures (if using a membrane press), even if it reduces the hourly throughput.

- If your primary focus is ensuring high filtrate quality (e.g., for water reclamation): Focus on selecting the correct filter cloth and controlling the initial fill rate, accepting that this may place a constraint on maximum capacity.

By following this testing methodology, you can confidently specify and operate a filter press based on empirical data, ensuring it meets your project's precise requirements.

Summary Table:

| Key Metric | Description | Importance for Capacity |

|---|---|---|

| Final Cake Solids (%) | Dry solids percentage in the discharged cake | Determines the effectiveness of liquid removal |

| Cake Density (kg/m³) | Mass per unit volume of the filter cake | Converts press volume into dry solids mass |

| Cake Thickness (mm) | Optimal thickness established during testing | Balances batch volume vs. filtration time |

| Total Cycle Time (hours) | Time for one full batch (fill, filter, discharge) | Directly impacts hourly throughput (kg/hour) |

Need to accurately size a filter press for your specific slurry?

At KINTEK, we specialize in providing laboratory equipment and consumables to help you conduct precise pilot-scale tests. Our expertise ensures you gather the critical data—like cake solids, density, and cycle time—needed to calculate your filter press capacity with confidence.

Contact us today using the form below to discuss your lab's filtration needs and discover how KINTEK can support your process optimization.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System