The right laboratory equipment is chosen not by its features, but by a rigorous analysis of your specific application, required throughput, and the total cost of ownership. This process moves beyond the initial purchase price to evaluate the long-term financial and operational impact of an instrument, ensuring it serves as a strategic asset rather than a costly liability.

Choosing laboratory equipment is fundamentally an exercise in risk management. The goal is to de-risk your scientific or production goals by selecting a tool that reliably and cost-effectively delivers the results you need, both today and in the future.

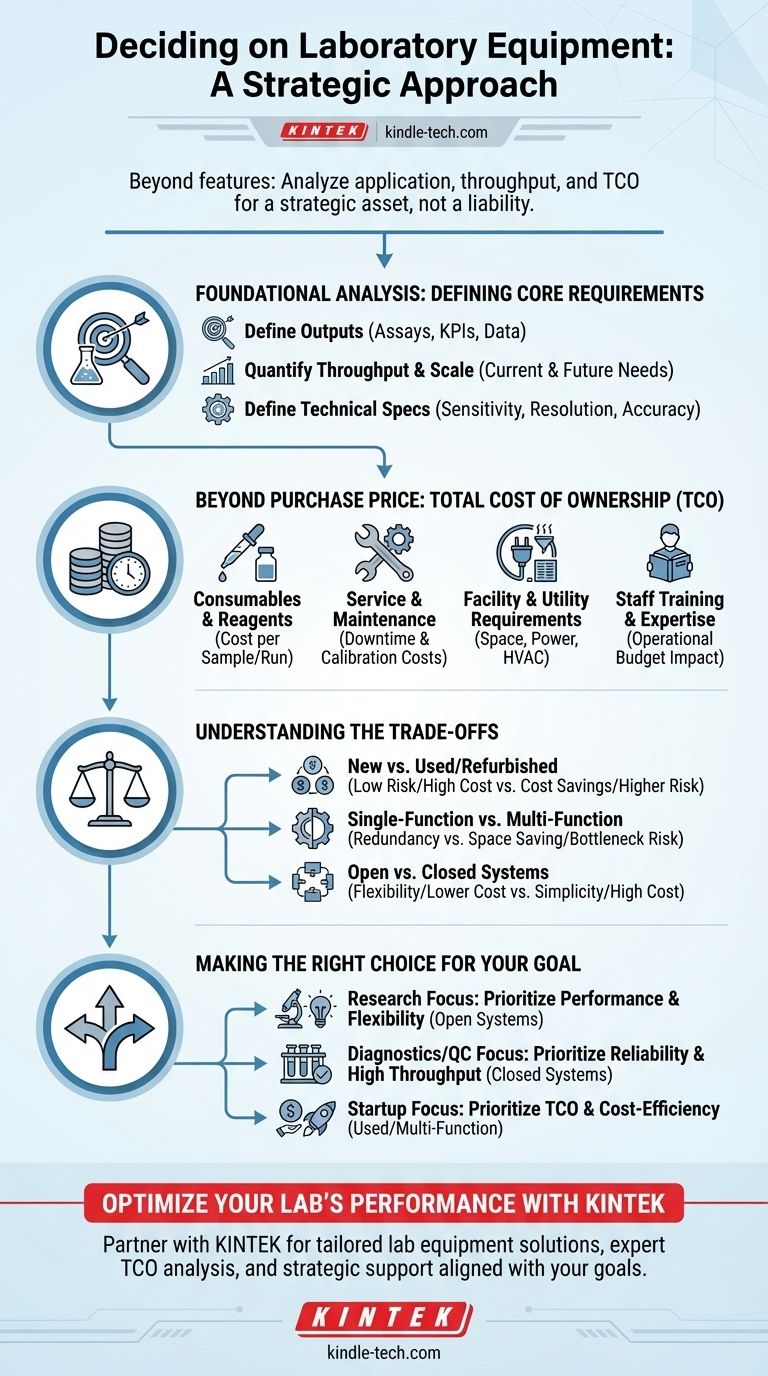

Foundational Analysis: Defining Your Core Requirements

Before you look at a single product brochure, you must first define the problem you are trying to solve. The equipment is the means to an end, not the end itself.

Start with the End Goal: What Are Your Outputs?

The most critical first step is to precisely define the data, sample, or product you need to generate. What specific assays will you run? What are the key performance indicators of a successful outcome?

This clarity on the final output will dictate the fundamental technology you require, filtering out a vast number of irrelevant options from the very beginning.

Quantify Your Throughput and Scale

You must quantify your operational needs. Will this instrument be used for a few precious samples a week, or will it need to process hundreds of samples per day?

Consider not only your current needs but also your projected growth over the next 3-5 years. A system that is perfect for your startup phase may become a debilitating bottleneck a year later.

Define Your Technical Specifications

With your outputs and scale defined, you can now list the necessary technical specifications. This includes parameters like sensitivity, resolution, dynamic range, temperature control accuracy, and sample volume capacity.

Be specific and realistic. Demanding specifications you don't truly need will dramatically increase costs and limit your options.

Beyond the Purchase Price: The Total Cost of Ownership (TCO)

The sticker price is often the smallest part of an instrument's true cost. A thorough TCO analysis is what separates a good purchasing decision from a disastrous one.

Consumables and Reagents

Many business models rely on the "razor and blades" approach. The instrument itself may be affordable, but it locks you into purchasing expensive, proprietary consumables or reagents.

Always calculate the cost per sample or cost per run, including all necessary consumables. This figure is a far more accurate financial metric than the initial purchase price.

Service, Maintenance, and Calibration

What is the cost of an annual service contract? What is the vendor's guaranteed response time if the machine goes down? Downtime is a massive hidden cost.

Furthermore, consider the frequency and cost of required calibration. A reliable, low-maintenance instrument can easily justify a higher initial price over its lifetime.

Facility and Utility Requirements

An instrument doesn't exist in a vacuum. Does it require a dedicated high-amperage electrical circuit, specialized gas lines, plumbing, or significant ventilation (HVAC) upgrades?

These facility costs can be substantial and must be factored into the total project budget. Ensure you have the physical space and infrastructure to support the equipment.

Staff Training and Expertise

Who will operate and maintain the equipment? Complex instruments may require hiring specialized personnel or investing in significant, and often costly, staff training. The ease of use and the level of automation can have a direct impact on your operational budget.

Understanding the Trade-offs

Every equipment choice involves balancing competing priorities. Being aware of these trade-offs is crucial for making an informed decision.

New vs. Used/Refurbished Equipment

New equipment comes with a full warranty, the latest technology, and dedicated vendor support. This is the lowest-risk, but highest-cost, option.

Used or refurbished equipment can offer dramatic cost savings. However, it comes with a higher risk of failure, potential lack of support, and may not have the performance of newer models. This is a viable option if you have in-house technical expertise for maintenance and repair.

Single-Function vs. Multi-Function Platforms

A multi-function instrument can save significant lab space and initial capital by combining several capabilities into one box.

The primary drawback is that it can become a workflow bottleneck, as only one function can be used at a time. A failure in one mode can render the entire platform unusable. Single-function instruments, while taking up more space, provide redundancy and parallel workflows.

Open vs. Closed Systems

This is one of the most significant strategic decisions. Closed systems lock you into a single vendor for all reagents and consumables. They offer simplicity and streamlined support, but at a high long-term cost and with zero flexibility.

Open systems allow you to use reagents and consumables from third-party suppliers. This provides flexibility and can dramatically lower running costs, but often requires more in-house expertise to develop and validate protocols.

Making the Right Choice for Your Goal

To finalize your decision, integrate your analysis into an actionable plan. Prioritize your needs based on your lab's core mission.

- If your primary focus is cutting-edge research: Prioritize performance specifications and system flexibility (open systems) to enable novel applications and discovery.

- If your primary focus is routine diagnostics or QC: Prioritize reliability, high throughput, low cost-per-sample, and a strong service contract, making closed systems a potentially better fit.

- If you are a startup with limited capital: Aggressively evaluate the total cost of ownership of used equipment or multi-function platforms, while carefully planning for the risks of potential downtime.

A well-equipped lab is not one with the most expensive tools, but one where every instrument is a deliberate and strategic asset aligned with your goals.

Summary Table:

| Key Decision Factor | Description |

|---|---|

| Core Requirements | Define outputs, throughput, and technical specs before evaluating equipment. |

| Total Cost of Ownership (TCO) | Consider consumables, maintenance, facility upgrades, and staff training costs. |

| Trade-offs | Balance new vs. used, single-function vs. multi-function, and open vs. closed systems. |

| Goal Alignment | Prioritize performance for research, reliability for diagnostics, or cost-efficiency for startups. |

Optimize your lab’s performance and budget with the right equipment strategy. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your unique needs—whether you’re advancing research, scaling diagnostics, or launching a startup. Let our experts help you evaluate TCO, avoid costly pitfalls, and select instruments that align with your goals. Contact us today to discuss your laboratory requirements and discover how KINTEK can support your success!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does a constant-temperature laboratory shaker support microbial toxicity testing? Ensure Accurate Nanocomposite Data

- What temperature does THC distillate? Find Your Perfect Vaping Sweet Spot

- What is the effect of catalyst on pyrolysis? Control Reaction Pathways for Higher-Value Products

- What are ultralow temperature freezers and what are they used for? Preserve Critical Samples for Decades

- Is oil sludge hazardous? Understanding the Critical Risks and Regulations

- Can a jeweler tell if a diamond has been enhanced? Get the Truth About Diamond Treatments

- What are the critical functions of high-purity nitrogen during the biomass pyrolysis process? Enhance Product Integrity

- What is the sputtering yield of materials? Master Deposition Rates & Film Quality