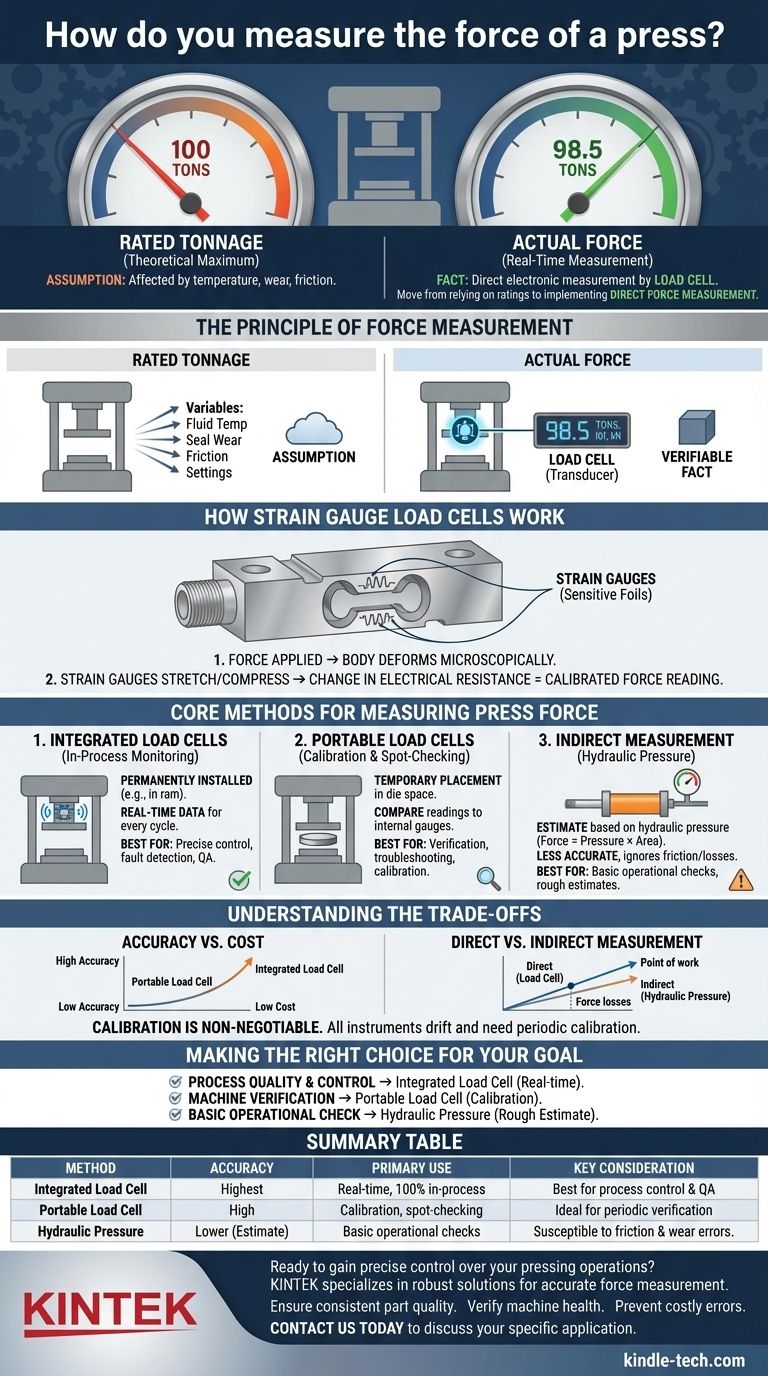

To measure the force of a press, you use a specialized sensor called a load cell, which is placed in the path of the force being applied. While a press is often rated in tons, this is its maximum theoretical capacity. A load cell provides a direct, real-time electronic measurement of the actual force being exerted during an operation, typically displayed in tons, pounds-force (lbf), or kilonewtons (kN).

While a press's tonnage rating tells you its potential, it doesn't confirm the actual force delivered at the workpiece. For true process control and quality assurance, you must move from relying on ratings to implementing direct force measurement.

The Principle of Force Measurement

Understanding the difference between a machine's rating and its real-world output is the first step toward gaining control over a pressing application. This is where precise measurement becomes critical.

From Rated Tonnage to Actual Force

A press may be rated for 100 tons, but the actual force it delivers can be affected by factors like hydraulic fluid temperature, seal wear, friction, and the specific settings of a job.

Simply trusting the machine's rating is an assumption. Measuring the force directly turns that assumption into a verifiable fact for every cycle.

The Role of the Load Cell

A load cell is a transducer that converts mechanical force into a measurable electrical signal. Think of it as a highly durable and extremely precise scale designed to withstand the immense forces inside a press.

When placed between the components of a press that exert force, it accurately measures the compression or tension being applied to the workpiece.

How Strain Gauge Load Cells Work

The most common type of load cell uses strain gauges. These are tiny, sensitive foils bonded to a precision-machined steel or aluminum body within the load cell.

As the press applies force, the load cell's body deforms microscopically. This slight deformation stretches or compresses the strain gauges, changing their electrical resistance. This change in resistance is directly proportional to the applied force and is converted into a calibrated reading.

Core Methods for Measuring Press Force

There are three primary methods for measuring press force, each with distinct applications and levels of accuracy. The method you choose depends on whether you need continuous monitoring or periodic checks.

1. Integrated Load Cells (In-Process Monitoring)

This is the most advanced and accurate method. A load cell is permanently installed as part of the press machinery, often in the ram, pitman arm, or frame tie rods.

This setup provides real-time force data for every single machine cycle. It enables precise control, fault detection (e.g., a missing part), and data logging for quality assurance.

2. Portable Load Cells (Calibration and Spot-Checking)

For verification and troubleshooting, a portable, disk-shaped load cell is used. This device is placed temporarily in the die space of the press, directly where the work is normally done.

The press is cycled at various force levels, and the readings from the portable load cell are compared to the press's internal gauges or settings. This is the standard method for calibrating a press and ensuring it is performing to specification.

3. Indirect Measurement via Hydraulic Pressure

In a hydraulic press, force can be estimated by measuring the pressure in the hydraulic cylinder. The formula is Force = Pressure × Area, where "Area" is the surface area of the hydraulic piston.

While simple and inexpensive, this method is less accurate. It measures the force generated by the hydraulic system, not the force delivered at the tool. It cannot account for force losses due to friction in the cylinder seals and press guiding system.

Understanding the Trade-offs

Choosing a measurement strategy requires balancing the need for accuracy with cost and implementation complexity. No single method is perfect for every situation.

Accuracy vs. Cost

Integrated load cells offer the highest accuracy and repeatability but represent the largest upfront investment. Indirect pressure measurement is the cheapest but also the least reliable, with potential inaccuracies of 10% or more. Portable load cells offer a middle ground, providing high accuracy for periodic audits without the cost of a full system integration.

Direct vs. Indirect Measurement

Direct measurement with a load cell is always superior. It measures the force at the point of work, which is the only force that matters for the quality of the finished part.

Indirect measurement (hydraulic pressure) only infers this force and is susceptible to errors from friction, temperature fluctuations, and mechanical wear, which can mask serious process issues.

Calibration is Non-Negotiable

All force measurement instruments, especially load cells and pressure gauges, can drift over time. They must be periodically calibrated against a known, traceable standard. An uncalibrated sensor provides a number, but it doesn't provide trustworthy information.

Making the Right Choice for Your Goal

Your measurement strategy should be dictated by your end goal, whether it's ensuring consistent part quality, verifying machine health, or simply confirming basic operation.

- If your primary focus is process quality and control: Use an integrated load cell system for real-time, 100% in-process force monitoring.

- If your primary focus is machine verification or periodic audits: A portable load cell system is the most practical and cost-effective tool for calibrating your equipment.

- If your primary focus is a basic operational check on a hydraulic press: Monitoring hydraulic pressure can provide a rough estimate, but be aware of its significant limitations.

By moving from assumed ratings to direct measurement, you gain precise and actionable control over your manufacturing process.

Summary Table:

| Method | Accuracy | Primary Use | Key Consideration |

|---|---|---|---|

| Integrated Load Cell | Highest | Real-time, 100% in-process monitoring | Best for process control and quality assurance |

| Portable Load Cell | High | Calibration, spot-checking, and audits | Ideal for periodic machine verification |

| Hydraulic Pressure | Lower (Estimate) | Basic operational checks | Susceptible to friction and wear errors |

Ready to gain precise control over your pressing operations?

Stop relying on theoretical ratings and start measuring the actual force delivered to your workpiece. KINTEK specializes in lab equipment and consumables, providing robust solutions for accurate force measurement in demanding environments.

Our expertise can help you:

- Ensure consistent part quality with real-time force monitoring.

- Verify machine health and performance with precise calibration tools.

- Prevent costly errors by detecting process faults early.

Contact us today via our contact form to discuss your specific application and discover the right force measurement solution for your laboratory or production needs.

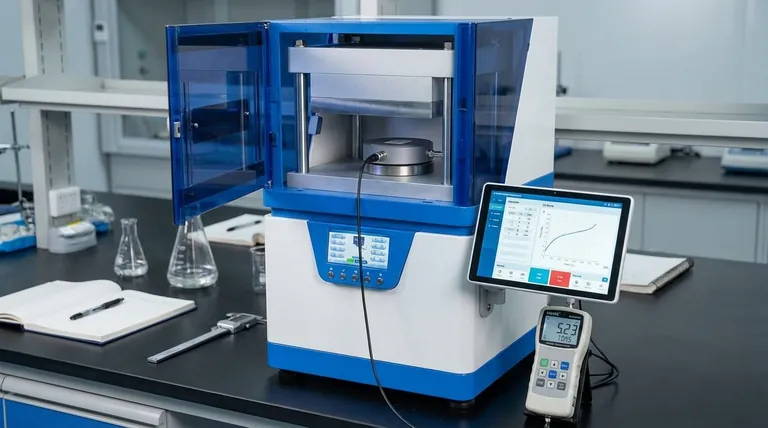

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the difference between manual and air compressed heat press? Choose the Right Tool for Your Production Needs

- How do you ensure the safe operation of equipment and machinery? A Proactive Guide to Risk Management

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained