The fundamental difference between a manual and an air-compressed heat press is how they generate and apply pressure. A manual press relies entirely on the operator's physical strength to close the machine and apply pressure, whereas an air-compressed (pneumatic) model uses an external air compressor to automate the process, delivering precise and effortless pressure with the push of a button. This single mechanical distinction has profound implications for consistency, production volume, and operator fatigue.

Your choice between a manual and an air-compressed heat press is a strategic decision. You are choosing between the lower upfront cost and simplicity of a manual press versus the superior consistency, precision, and scalability offered by a pneumatic system.

The Mechanics of Pressure Application

To choose the right tool, you must first understand how each machine accomplishes its primary task: applying consistent pressure at a specific temperature. The method of application is the core differentiator.

How Manual Heat Presses Work

A manual heat press operates using a simple lever system. The user physically pulls a handle down to close the heated platen onto the garment. The amount of pressure applied is subjective and depends entirely on the operator's strength and the machine's mechanical adjustment knob. This pressure is often described in qualitative terms like "light," "medium," or "firm."

How Air-Compressed (Pneumatic) Presses Work

A pneumatic heat press is connected to a separate air compressor. When activated, this compressor sends pressurized air into a cylinder within the press, which drives a piston to close the platen automatically. The pressure is precisely controlled by a regulator, measured in Pounds per Square Inch (PSI), and is applied evenly and consistently every single time without any physical effort from the operator.

Key Differentiators for Your Operation

The mechanical differences directly translate into significant operational advantages and disadvantages, impacting everything from the quality of your final product to the efficiency of your workflow.

Consistency and Quality Control

The single greatest advantage of an air-compressed press is repeatable consistency. Setting the regulator to a specific PSI ensures that every single item receives the exact same amount of pressure. This is critical for achieving professional, uniform results, especially with sensitive transfers like DTF (Direct-to-Film) or sublimation.

Manual presses, by contrast, are subject to human variability. The pressure applied can differ slightly from one press to the next, and an operator's strength may wane over a long production run, leading to potential inconsistencies in the final products.

Operator Effort and Fatigue

For low-volume or hobbyist use, the physical effort of a manual press is manageable. However, for any significant production volume, operator fatigue becomes a serious limiting factor. Repeatedly closing a manual press with firm pressure is physically demanding and can reduce productivity.

An air-compressed press eliminates this issue entirely. The operator simply pushes a button, freeing them from physical strain and allowing for longer, more efficient production runs with less risk of fatigue-related errors.

Precision and Adjustability

Pneumatic presses offer quantitative pressure control. If a specific transfer material requires 60 PSI, you can dial the regulator to that exact number.

Manual presses rely on a tactile feel. You tighten an adjustment knob until it "feels" right for firm pressure. While effective, this method lacks the fine-tuned precision required for some advanced or commercial applications.

Understanding the Trade-offs

The superior performance of a pneumatic press comes with clear trade-offs in cost, space, and complexity that are critical to consider.

The Upfront Investment

This is the most significant advantage of a manual press. It is a self-contained unit with a much lower initial purchase price, making it the ideal entry point for startups, hobbyists, or businesses with tight budgets.

An air-compressed system requires two separate purchases: the press itself and a compatible air compressor. This makes the initial investment significantly higher.

Space and Noise Considerations

A manual press is a single, relatively quiet piece of equipment. An air compressor, however, requires additional floor space and can be extremely loud during operation. This is a crucial consideration for home-based businesses or workshops where noise levels are a concern.

Maintenance and Simplicity

With fewer components, a manual press is mechanically simpler and generally easier to maintain. An air-compressed press introduces more points of potential failure, including the compressor itself, air hoses, fittings, and pressure regulators, which may require periodic maintenance.

Making the Right Choice for Your Needs

Selecting the right heat press is about aligning the tool's capabilities with your specific operational goals and constraints.

- If your primary focus is starting out, hobby use, or very low-volume production: A manual heat press is the most logical and cost-effective choice.

- If your primary focus is scaling your business and achieving consistent, professional-grade quality: An air-compressed heat press is a necessary investment for its precision and ability to reduce labor costs.

- If your primary focus is minimizing noise or working in a small space: The self-contained, quiet nature of a manual press makes it the more practical option.

Ultimately, understanding these core differences empowers you to invest in the right tool that will support your long-term production goals, not just your immediate budget.

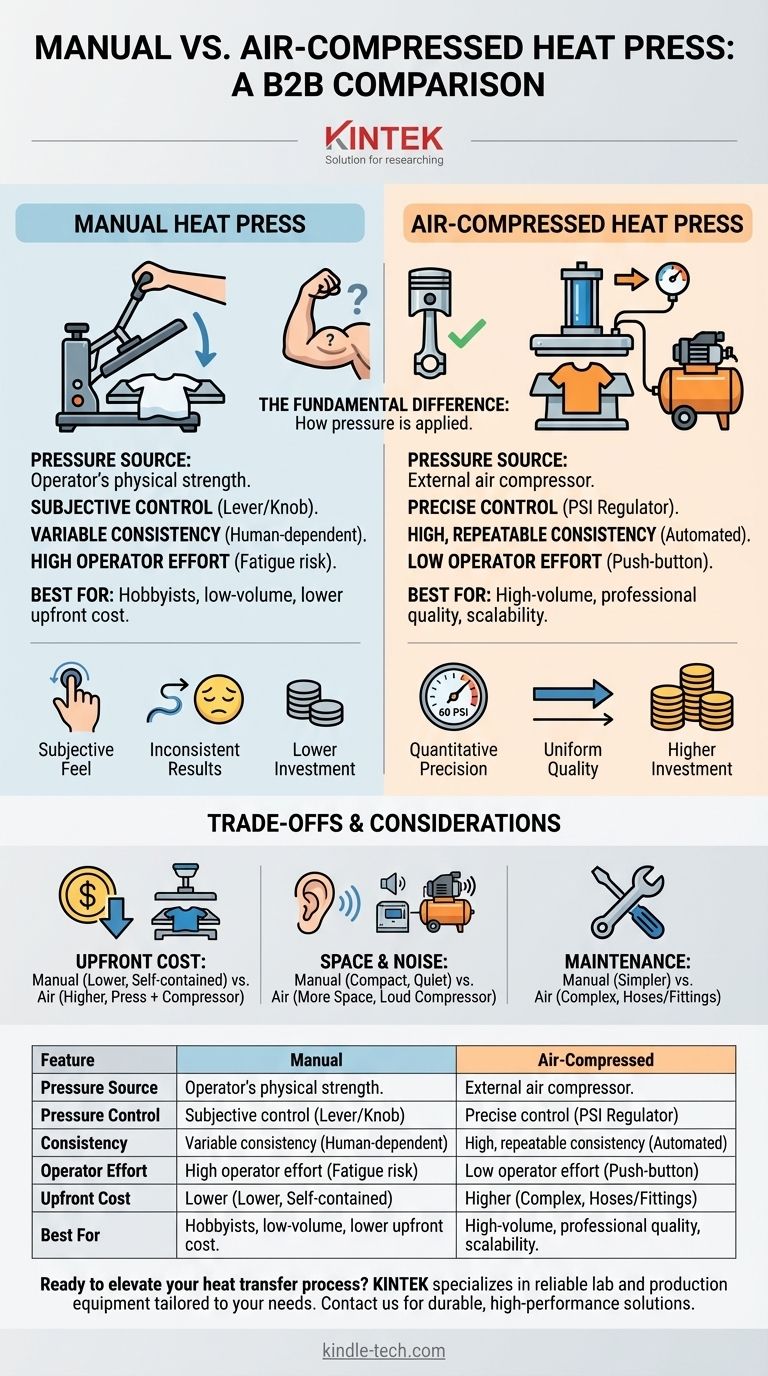

Summary Table:

| Feature | Manual Heat Press | Air-Compressed Heat Press |

|---|---|---|

| Pressure Source | Operator's physical strength | External air compressor |

| Pressure Control | Subjective (lever/knob) | Precise, quantitative (PSI regulator) |

| Consistency | Variable (depends on operator) | High, repeatable every time |

| Operator Effort | High (can cause fatigue) | Low (push-button operation) |

| Upfront Cost | Lower | Higher (press + compressor) |

| Best For | Hobbyists, low-volume startups | High-volume, professional production |

Ready to elevate your heat transfer process with the right equipment?

At KINTEK, we specialize in providing reliable lab and production equipment, including heat presses tailored to your specific needs. Whether you're a startup looking for an affordable manual press or a growing business needing the precision of an air-compressed system, we have the expertise to guide you.

Contact us today via our contact form to discuss your requirements and discover how KINTEK can support your success with durable, high-performance solutions.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Lab Heat Press

People Also Ask

- How does a heated laboratory hydraulic press facilitate densification in CSP? Optimize Mg-doped NASICON Sintering

- What is hot press laminate? A Durable, Non-Porous Surface Created by Heat and Pressure

- How does a laboratory heating and stirring device assist in loading Pt particles? Precision Synthesis Explained

- What's the difference between a heat press machine and an iron? Achieve Professional, Durable Apparel Transfers

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What is the purpose of using a heating device for 180°C LLZA lithium treatment? Optimize Solid-State Interface

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis