At its core, a forging press operates by using immense compressive force to shape a piece of metal, known as a billet or ingot, between two dies. Unlike casting, which involves molten metal, forging plastically deforms the material in its solid state. This controlled pressure and deformation process forces the metal to conform to the shape of the die cavities.

The true value of a forging press lies not just in shaping metal, but in fundamentally improving it. The process refines the material's internal grain structure, aligning it with the part's final shape, which results in unparalleled strength, toughness, and fatigue resistance.

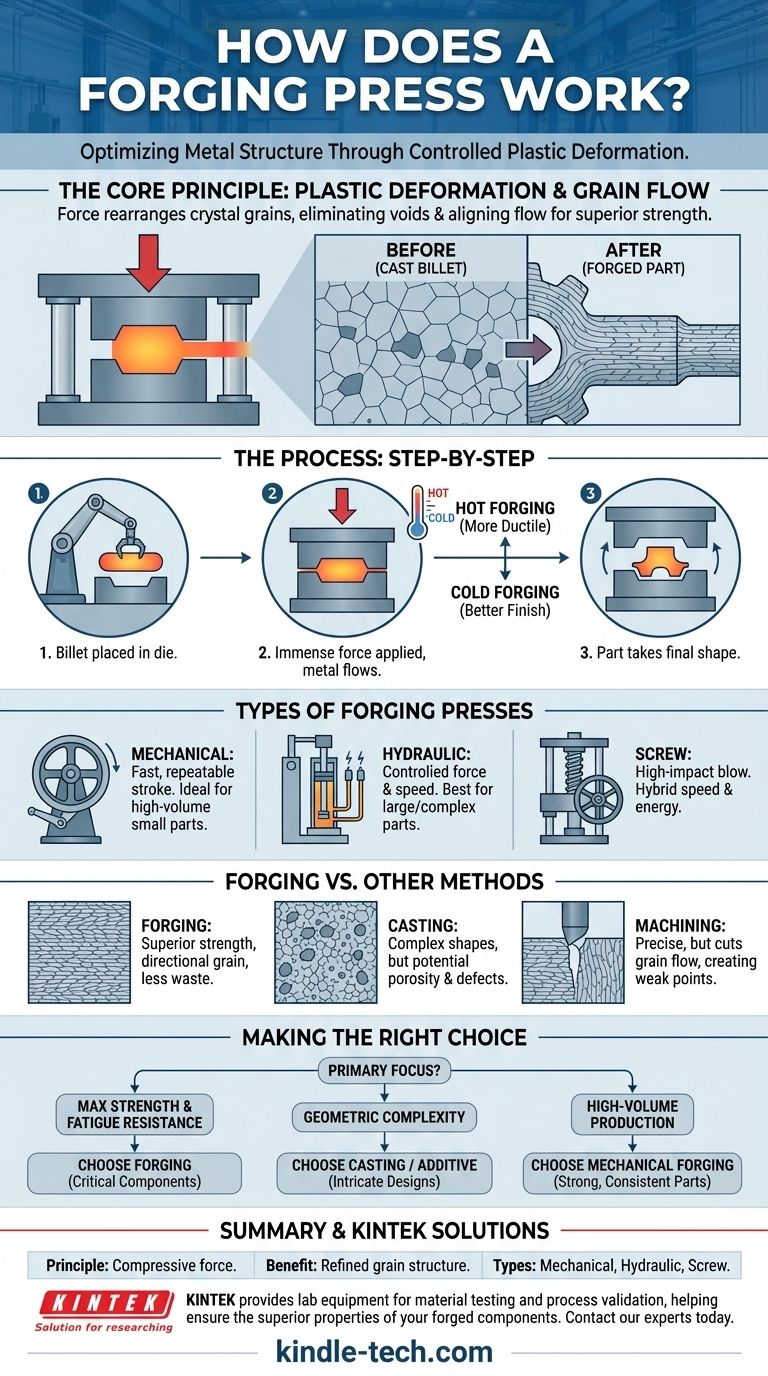

The Core Principle: Controlled Plastic Deformation

What is Plastic Deformation?

Plastic deformation is the permanent change in a solid body's shape in response to applied force. Imagine kneading dough; you are not melting it, but reshaping it by moving the material around.

Forging does the same thing to metal on a microscopic level. The immense pressure forces the metal's crystal grains to deform and elongate, eliminating internal voids and aligning the grain flow to the contours of the component.

The Role of the Die

The die is the heart of the forging operation. It is typically a two-part mold, with a lower die half that is stationary and an upper die half that is attached to the moving ram of the press.

The billet is placed on the lower die, and the press action brings the upper die down with tremendous force. The metal, having nowhere else to go, flows and fills the cavities of the die, taking on its final shape.

Hot, Warm, or Cold Forging

The temperature of the billet is a critical variable.

- Hot Forging: Most forging is done at high temperatures (above the material's recrystallization point). Heat makes the metal significantly more ductile and easier to shape with less force.

- Cold Forging: Performed at or near room temperature, this process requires much higher forces but produces parts with excellent surface finish and dimensional accuracy, often requiring no secondary machining.

Types of Forging Presses: A Comparison of Force

The method used to generate the compressive force defines the type of press and its ideal application.

Mechanical Presses

Mechanical presses use a motor-driven flywheel to store energy, which is then transferred to the ram via a crank or eccentric shaft mechanism. They are defined by a preset, continuous stroke.

This design makes them extremely fast and repeatable, which is ideal for high-volume production of small to medium-sized parts like automotive components and hand tools.

Hydraulic Presses

Hydraulic presses use hydraulic fluid and pistons to move the ram. The force is generated by a pump that pressurizes the fluid.

Their key advantage is complete control. Force and speed can be varied at any point during the stroke. They deliver constant force regardless of the ram's position, making them perfect for very large parts (like aerospace structures) or complex shapes that require the metal to flow slowly into deep die cavities.

Screw Presses

Screw presses offer a hybrid approach. A motor accelerates a large flywheel, which then drives a vertical screw to push the ram down. The energy from the flywheel is delivered in a single, high-impact blow.

This combines some of the speed of a mechanical press with the energy-based forging of a hammer, making it versatile for a wide range of parts requiring both precision and force.

Understanding the Trade-offs: Forging vs. Other Methods

Forging vs. Casting

Casting involves pouring molten metal into a mold. While excellent for complex shapes, the cooling process can create random grain structures, porosity, and internal defects.

Forging's refined, directional grain structure produces parts that are mechanically stronger and more reliable under stress and impact. The trade-off is often higher tooling (die) costs and some limitations on geometric complexity.

Forging vs. Machining

Machining creates a part by cutting away material from a larger block (subtractive manufacturing). This process cuts through the metal's inherent grain flow, potentially creating weak points.

Forging is a "near-net-shape" process that moves material into place, preserving and enhancing grain flow. This not only creates a stronger part but also generates significantly less material waste.

The Limitations of Forging

The primary limitations of forging are the high initial cost of creating the hardened steel dies and the difficulty in producing extremely intricate shapes with undercuts or internal passages. For this reason, forging is most cost-effective for medium to high production runs where the tooling cost can be amortized over many parts.

Making the Right Manufacturing Choice

Choosing a process depends entirely on the component's final application and required performance.

- If your primary focus is maximum strength and fatigue resistance: Forging is the superior choice for critical components that cannot fail, such as engine crankshafts, aircraft landing gear, or high-pressure valves.

- If your primary focus is low-volume or prototype production: The high die cost of forging makes CNC machining or casting more economical for one-off or small-batch parts.

- If your primary focus is geometric complexity: Casting or additive manufacturing (3D printing) can achieve intricate designs that are impossible to forge in a single operation.

- If your primary focus is high-volume production of strong, consistent parts: Mechanical press forging provides an unmatched balance of strength, speed, and cost-efficiency.

Understanding how a forging press works is to understand that you are not just changing a part's shape, but optimizing its very structure for performance.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Plastic deformation of solid metal using immense compressive force. |

| Primary Benefit | Refines internal grain structure, aligning it with the part's shape for superior mechanical properties. |

| Common Types | Mechanical Presses (fast, repeatable), Hydraulic Presses (controlled force), Screw Presses (high-impact). |

| Typical Applications | Automotive components, aerospace structures, hand tools, high-pressure valves. |

Ready to Forge Stronger Components?

Choosing the right manufacturing process is critical for your product's performance and reliability. KINTEK specializes in providing the lab equipment and consumables necessary for material testing and process development, helping you validate the superior properties of forged parts.

Contact our experts today via our Contact Form to discuss how our solutions can support your material science and manufacturing challenges, ensuring you achieve the strength and durability your applications demand.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy