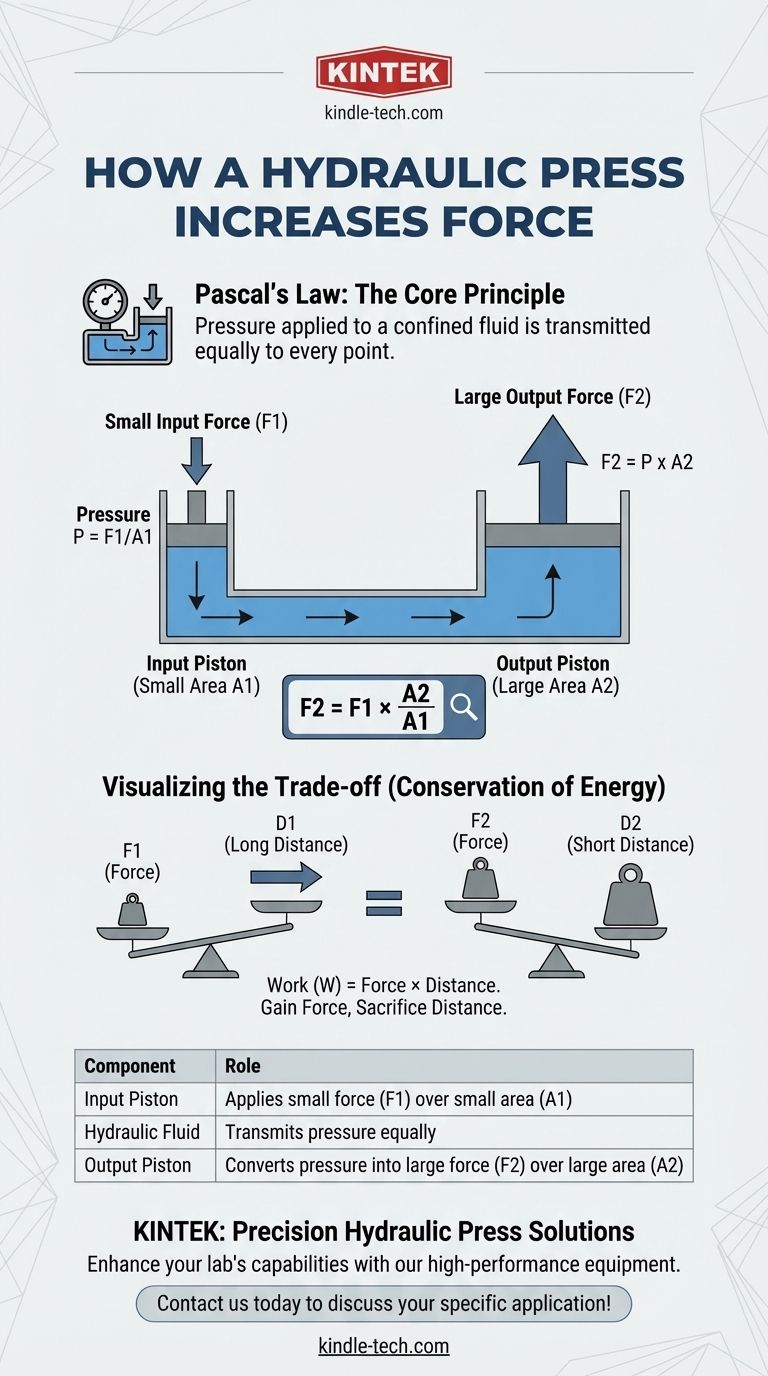

At its core, a hydraulic press multiplies force by applying a fundamental principle of fluid mechanics known as Pascal's Law. An initial force is applied to a small area in an enclosed, incompressible fluid, creating pressure. Because this pressure is transmitted equally throughout the fluid, it acts on a much larger area on the output side, resulting in a proportionally larger output force.

The central mechanism is force multiplication through pressure. A small force acting on a small piston creates pressure that is transmitted through a fluid. This same pressure, when applied to a much larger piston, generates a massive output force, trading a long input distance for a short, powerful output stroke.

The Core Principle: Pascal's Law

The entire operation of a hydraulic press hinges on a single, elegant concept discovered by Blaise Pascal in the 17th century. Understanding this law is key to understanding the machine.

What is Pascal's Law?

Pascal's Law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally to every other point throughout the fluid and to the walls of its container.

In simple terms, if you squeeze a sealed container of water, the pressure increases everywhere inside that container at the same time and by the same amount.

Pressure, Force, and Area: The Key Formula

The relationship between pressure, force, and area is the mathematical foundation of the hydraulic press. The formula is:

Pressure (P) = Force (F) / Area (A)

This means the pressure in a system is the amount of force exerted over a specific area. A small force on a tiny area can create the same pressure as a large force on a big area.

How the Press Exploits This Law

A hydraulic press uses two connected cylinders, each with a piston, but of very different sizes.

The input piston (or plunger) has a small surface area (A1). A small input force (F1) is applied to it. This creates pressure in the hydraulic fluid: P = F1 / A1.

According to Pascal's Law, this pressure (P) is transmitted unchanged to the larger output piston, which has a much larger surface area (A2). The resulting output force (F2) is therefore: F2 = P × A2.

By substituting the first equation into the second, we see that the output force is F2 = (F1 / A1) × A2, or simply F2 = F1 × (A2 / A1). The force is multiplied by the ratio of the areas.

Visualizing Force Multiplication

Imagine the system as two pistons connected by a tube filled with oil.

The Input Piston (Effort)

This is the small piston where you or a small motor applies a modest force. For example, applying 100 pounds of force to a piston with a 1-square-inch area generates a pressure of 100 pounds per square inch (PSI) in the fluid.

The Incompressible Fluid

The hydraulic fluid (typically an oil) is crucial because it is nearly incompressible. It transmits pressure efficiently without losing significant energy to being squeezed itself. It acts as a seamless medium for transferring power.

The Output Piston (Load)

This is the large piston that does the work, like crushing a car or forming a metal sheet. If this piston has an area of 100 square inches, the 100 PSI of pressure from the fluid now acts on it.

The resulting output force is Force = Pressure × Area, or 100 PSI × 100 sq. in. = 10,000 pounds. Your initial 100-pound effort has been multiplied one hundred times.

Understanding the Trade-offs: The Law of Conservation of Energy

The immense force multiplication of a hydraulic press can feel like getting something for nothing, but it comes at a cost dictated by the laws of physics.

The Myth of "Free" Force

You cannot create energy from nothing. A hydraulic press is a force multiplier, not an energy multiplier. The work done on the input side is (ideally) equal to the work done on the output side.

The Distance Trade-off

Work is defined as Work = Force × Distance.

To conserve energy, if you multiply the force, you must reduce the distance traveled. To move the 10,000-pound output piston by just one inch, you must move the 100-pound input piston by 100 inches.

This is the fundamental trade-off: you sacrifice distance to gain force. This is why the small plunger on a hydraulic jack must be pumped many times to lift a car just a few inches.

Inefficiency: Heat and Friction

In any real-world machine, some energy is lost. In a hydraulic system, this occurs primarily through friction between the pistons and their cylinder walls and through the internal friction of the fluid itself, which generates heat. This means the actual output work will always be slightly less than the input work.

Making the Right Choice for Your Application

Understanding these principles allows you to see how a hydraulic system is designed to meet specific goals.

- If your primary focus is maximum force multiplication: You must maximize the ratio of the output piston's area to the input piston's area.

- If your primary focus is speed: You must use a high-volume pump to move a large amount of fluid quickly, which is necessary to make the large output piston travel a meaningful distance.

- If your primary focus is efficiency: You need to use high-quality seals, polished cylinder surfaces, and the correct fluid viscosity to minimize energy losses from friction and heat.

By manipulating pressure, area, and fluid flow, a hydraulic system provides a powerful and versatile method for converting a small effort into an immense output force.

Summary Table:

| Component | Role in Force Multiplication |

|---|---|

| Input Piston (Small) | Applies a small input force (F1) over a small area (A1), creating high pressure (P). |

| Hydraulic Fluid | Transmits pressure equally throughout the system (Pascal's Law). |

| Output Piston (Large) | Converts pressure (P) into a large output force (F2) over a large area (A2). |

| Force Multiplication Formula | F2 = F1 × (A2 / A1) |

Ready to harness the power of hydraulic force multiplication in your lab or workshop? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision, durability, and efficiency. Whether you need crushing, molding, or pressing solutions, our expertise ensures you get the right equipment for your specific application. Contact us today to discuss how KINTEK can enhance your laboratory’s capabilities with reliable hydraulic systems!

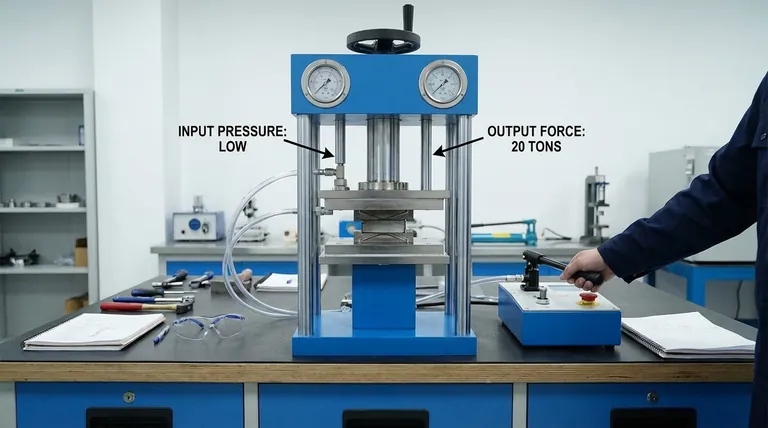

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy