At its core, a hydraulic press works by multiplying force using a confined, incompressible fluid. Based on a fundamental principle of physics, it uses a small piston to apply pressure to a fluid, and that pressure is then transferred to a much larger piston. This second piston moves with a proportionally greater force, allowing the machine to generate immense compressive power from a relatively small initial effort.

The genius of a hydraulic press lies in its application of Pascal's Law. It doesn't create energy, but rather converts a small, manageable input force into a massive, work-performing output force, all through the simple medium of a confined fluid.

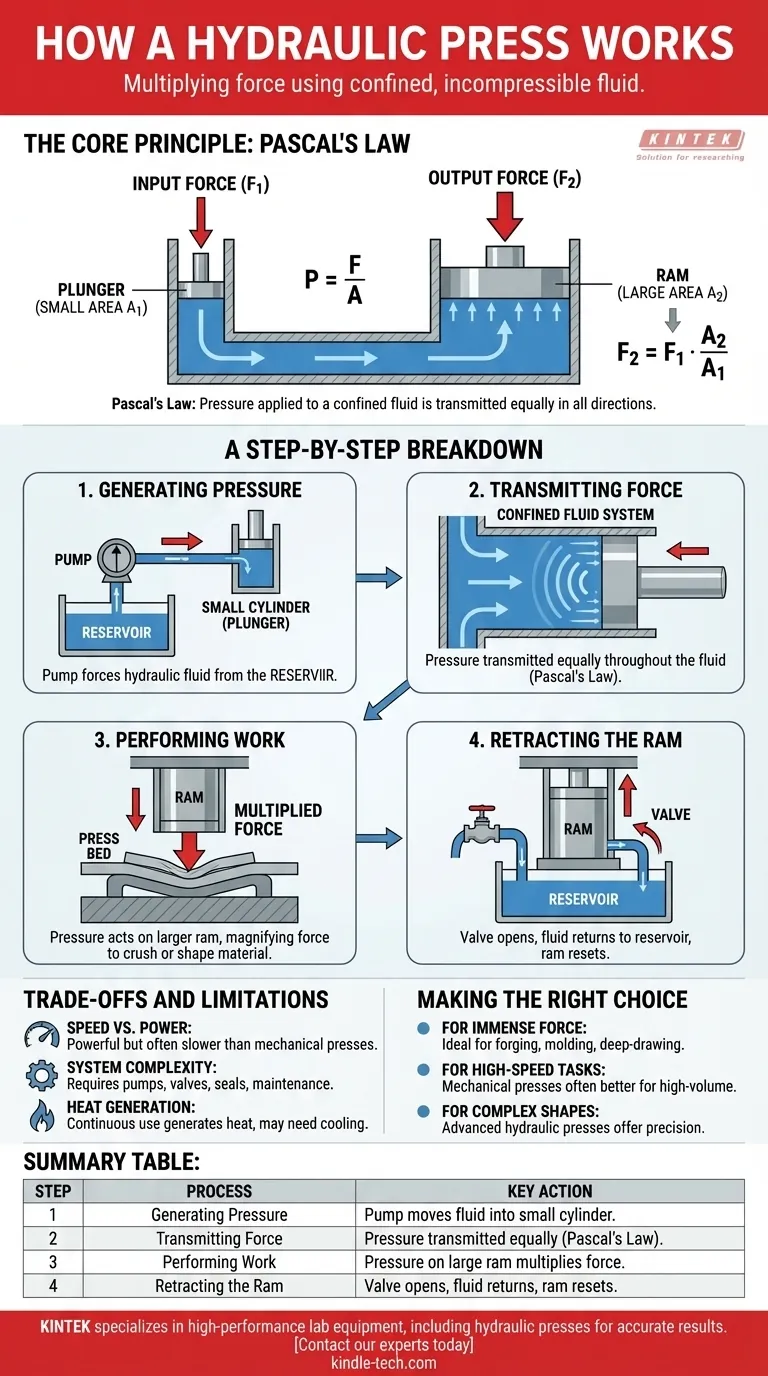

The Core Principle: Pascal's Law Explained

To truly understand how a hydraulic press functions, you must first grasp the scientific law that governs it. This single principle is the key to its entire operation.

What is Pascal's Law?

Pascal's Law states that when pressure is applied to a fluid in a confined space, that pressure is transmitted equally and without loss in all directions throughout the fluid.

Think of squeezing a sealed water bottle. The pressure you apply with your hand is felt equally by every part of the bottle's inner surface. Hydraulic systems harness this exact behavior.

The Magic of Force Multiplication

The system uses two interconnected cylinders of different sizes: a small one (the plunger) and a large one (the ram). A modest force is applied to the plunger.

Because pressure equals force divided by area (P = F/A), the pressure created is transmitted through the hydraulic fluid to the ram. Since the ram has a much larger surface area, the same pressure results in a much greater output force, effectively multiplying the initial effort.

A Step-by-Step Breakdown of the Operation

While the principle is simple, the mechanical process involves a sequence of coordinated actions to perform work and reset for the next cycle.

Step 1: Generating Pressure

The process begins when a pump, powered by a motor, moves hydraulic fluid from a reservoir into the smaller cylinder (the plunger). Applying force to this plunger pressurizes the confined fluid within the system.

Step 2: Transmitting Force

Instantly, according to Pascal's Law, this pressure is transmitted throughout the entire hydraulic system. The fluid, being nearly incompressible, transfers this energy efficiently to the larger cylinder (the ram).

Step 3: Performing Work

The pressure acts upon the entire surface of the ram's piston. Because the ram's surface area is significantly larger than the plunger's, the resulting force is magnified. This drives the ram down with immense power, crushing, forging, or shaping the material placed on the press bed.

Step 4: Retracting the Ram

Once the pressing operation is complete, a valve is opened. This releases the pressure, allowing the hydraulic fluid to flow back into the reservoir. The ram then retracts, often aided by gravity or smaller return pistons, ready for the next cycle.

Understanding the Trade-offs and Limitations

While incredibly powerful, hydraulic presses are not the solution for every application. Their design creates specific advantages and disadvantages.

Speed vs. Power

Hydraulic presses excel at delivering massive, controllable force. However, moving the large volume of fluid required to actuate the ram can make them slower than their mechanical counterparts, which are often used for high-speed stamping.

System Complexity and Maintenance

The system relies on a network of pumps, hoses, valves, and seals to contain high-pressure fluid. This introduces a risk of leaks and requires regular maintenance to ensure the system remains sealed and efficient.

Heat Generation

The continuous movement and pressurization of hydraulic fluid generate heat. In high-duty cycle applications, this may necessitate cooling systems to maintain optimal fluid viscosity and prevent damage to components.

Making the Right Choice for Your Goal

Understanding the operational principles allows you to determine where a hydraulic press is the most effective tool for the job.

- If your primary focus is immense, controllable force: A hydraulic press is ideal for forging, molding, and deep-drawing operations where the precise application of massive pressure is critical.

- If your primary focus is high-speed, repetitive tasks: A mechanical press is often a better fit for applications like high-volume stamping, as it typically offers a faster cycle time.

- If your primary focus is complex shapes and precision: Modern hydraulic presses with advanced controls offer unparalleled command over speed and pressure, enabling the creation of unique and intricate geometries.

By mastering the simple principle of fluid pressure, the hydraulic press stands as one of engineering's most powerful and versatile tools.

Summary Table:

| Step | Process | Key Action |

|---|---|---|

| 1 | Generating Pressure | Pump moves fluid into a small cylinder (plunger). |

| 2 | Transmitting Force | Pressure is transmitted equally through the fluid (Pascal's Law). |

| 3 | Performing Work | Pressure acts on a large cylinder (ram), multiplying the force. |

| 4 | Retracting the Ram | Valve opens, fluid returns to reservoir, and ram resets. |

Need precise, powerful force for your lab or production needs?

KINTEK specializes in high-performance lab equipment, including hydraulic presses ideal for material testing, sample preparation, and R&D. Our solutions deliver the controlled, immense pressure required for accurate and repeatable results.

Contact our experts today to find the perfect hydraulic press for your application!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- How do a laboratory hydraulic press and alumina molds ensure ASSB integrity? Achieve Perfect Solid-State Densification

- What is an example of a hydraulic system in industry? The Power of Hydraulic Presses Explained

- What are the factor affecting pelletization technique? Mastering Material, Process, and Binder Variables

- What is manual hydraulic press? A Guide to Simple, High-Force Compression

- What are the limitations of compression molding? Slower Cycles, Simpler Designs, and Higher Labor

- Can XRF detect rare earth elements? A Guide to Rapid, Non-Destructive Analysis

- Why KBr disc is used in IR spectroscopy? Achieve High-Resolution Analysis of Solid Samples

- What task does a laboratory hydraulic press perform in Fe@C specimen preparation? Optimize Electromagnetic Testing