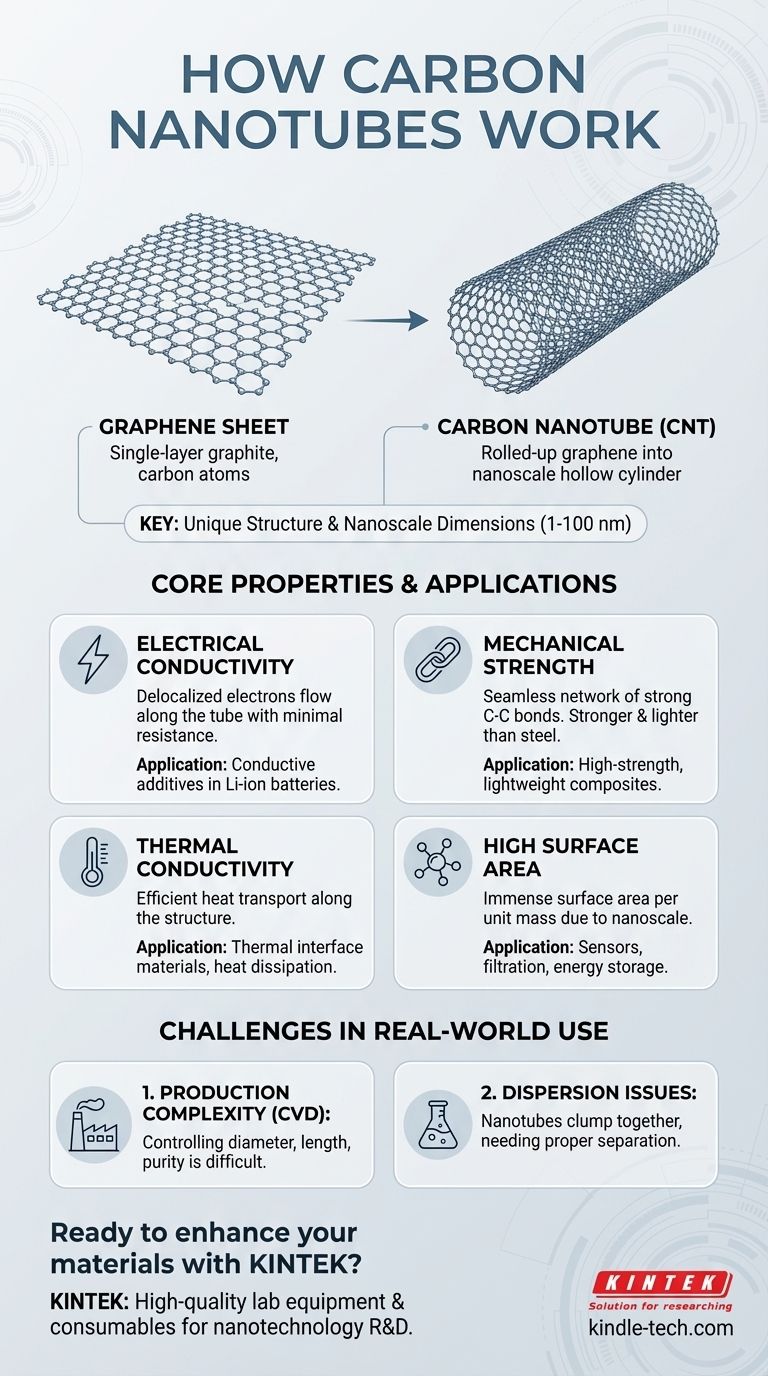

At their core, carbon nanotubes work by arranging carbon atoms into a unique, hollow cylindrical structure at the nanoscale. This specific shape, essentially a rolled-up sheet of single-layer graphite (graphene), is what gives them an extraordinary combination of mechanical strength, low weight, and electrical and thermal conductivity that is unmatched by almost any other material.

The power of a carbon nanotube isn't in the carbon itself, but in its near-perfect atomic arrangement. This structure allows electrons to flow with little resistance and withstand immense physical stress, making it a powerful additive for enhancing other materials.

What Are Carbon Nanotubes?

To understand how carbon nanotubes (CNTs) function, we first need to visualize their fundamental structure. It's simpler than it sounds.

A Rolled-Up Sheet of Graphene

Imagine a single, atom-thick sheet of carbon atoms arranged in a honeycomb lattice, like chicken wire. This is called graphene. Now, roll that sheet seamlessly into a tiny, hollow tube. That is a carbon nanotube.

This cylindrical structure is incredibly stable due to the strength of the carbon-carbon bonds, which are among the strongest chemical bonds in nature.

The Significance of Nanoscale

CNTs are nanomaterials, meaning their diameter is measured in nanometers (typically 1-100 nm). For perspective, a single nanotube can be thousands of times thinner than a human hair.

At this tiny scale, the rules of physics change. The high surface-area-to-volume ratio and quantum effects give these materials special physical and chemical properties that they wouldn't have at a larger scale.

The Core Properties That Drive Their Function

The unique structure of CNTs gives rise to several key properties. These properties explain why they are used in so many advanced applications.

Exceptional Electrical Conductivity

The delocalized electrons within the carbon lattice are free to move along the tube's length. This makes CNTs behave like molecular-scale wires, allowing them to conduct electricity with very little resistance.

This is precisely why they are used as conductive additives in lithium-ion batteries. A small amount of CNTs can create a highly efficient conductive network throughout the battery electrode, improving charge/discharge rates and overall lifespan.

Unmatched Mechanical Strength

The seamless network of strong carbon bonds makes CNTs one of the strongest and stiffest materials ever discovered relative to their density. They are incredibly lightweight yet have a tensile strength many times greater than steel.

This property is leveraged when CNTs are mixed into other materials, such as polymers or concrete, to create lightweight, high-strength composites.

Understanding the Trade-offs and Challenges

While their properties are remarkable, the practical application of CNTs is not without its difficulties. Understanding these challenges is key to evaluating their real-world potential.

The Challenge of Production

Synthesizing high-quality, uniform CNTs at a large scale remains a significant challenge. While Chemical Vapor Deposition (CVD) is the dominant commercial method, controlling the exact diameter, length, and purity is difficult.

This production complexity is a primary driver of their cost and can affect the final performance of any product they are incorporated into.

Issues with Dispersion

Due to their nanoscale size and strong intermolecular forces, nanotubes have a powerful tendency to clump together or "agglomerate."

If they are not properly separated and dispersed within a host material (like a polymer or liquid), they cannot impart their beneficial properties effectively. This is a major engineering hurdle in many applications.

How This Applies to Key Technologies

Your specific goal will determine which property of carbon nanotubes is most important.

- If your primary focus is energy storage (Batteries): Their exceptional electrical conductivity is the key, creating pathways for electrons to move quickly and efficiently.

- If your primary focus is material science (Composites): Their phenomenal strength-to-weight ratio allows you to create far stronger and lighter materials, from airplane parts to concrete.

- If your primary focus is electronics: Their nanoscale size and conductivity make them ideal candidates for creating smaller, faster transistors and transparent conductive films for displays.

Ultimately, carbon nanotubes function as high-performance additives that transfer their elite properties to a bulk material.

Summary Table:

| Property | How It Works | Key Application |

|---|---|---|

| Electrical Conductivity | Delocalized electrons flow with minimal resistance along the tube. | Conductive additives in lithium-ion batteries. |

| Mechanical Strength | Seamless network of strong carbon-carbon bonds. | High-strength, lightweight composites. |

| Thermal Conductivity | Efficient phonon transport along the tubular structure. | Thermal interface materials, heat dissipation. |

| High Surface Area | Nanoscale diameter provides immense surface area per unit mass. | Sensors, filtration, energy storage. |

Ready to enhance your materials with the power of carbon nanotubes?

KINTEK specializes in providing high-quality lab equipment and consumables to support your research and development in nanotechnology. Whether you are developing next-generation batteries, stronger composites, or advanced electronic components, our expertise can help you achieve superior results.

Contact us today to discuss how our solutions can meet your specific laboratory needs and drive your innovations forward.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is the sputtering target of gallium oxide? A Guide to High-Performance Ga₂O₃ Thin Films

- What are the key properties of Silver (Ag)? Discover the Element with Unmatched Electrical and Thermal Conductivity

- What are 4 applications of carbon nanotubes? Enhancing Batteries, Composites, Electronics & Sensors

- How does the sputtering method work? A Guide to Thin-Film Deposition via Atomic Bombardment

- What are the advantages of sputtering based thin film deposition? Achieve Superior Film Quality & Material Versatility

- What is the method of sputter deposition? A Guide to High-Quality Thin Film Coating

- What are the applications of graphene in electronics? Revolutionizing Performance, Energy, and Durability

- What are the different types of exfoliation for graphene? Choose the Right Method for Your Application