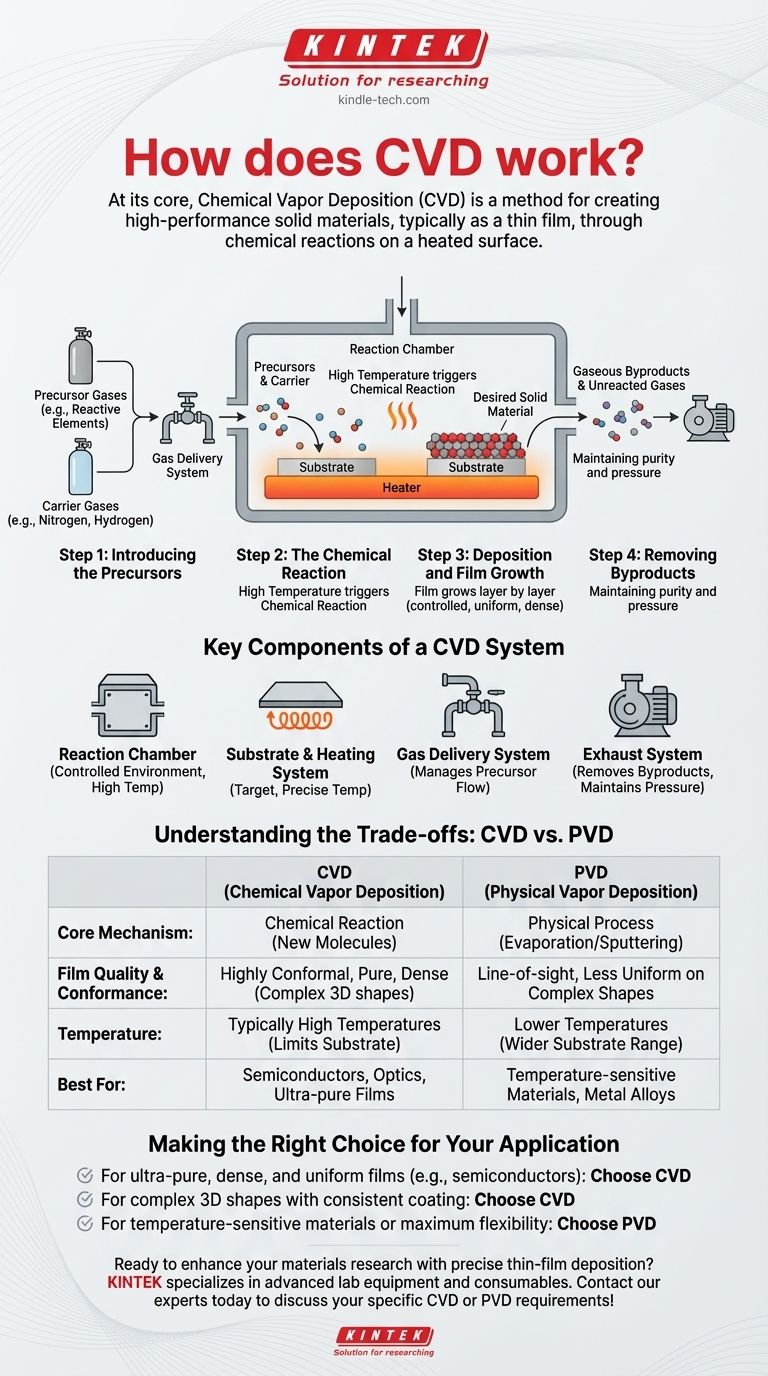

At its core, Chemical Vapor Deposition (CVD) is a method for creating high-performance solid materials, typically as a thin film. The process involves placing a target object, or substrate, into a reaction chamber and introducing specific gases. By applying energy, usually in the form of heat, these gases undergo a chemical reaction or decomposition on the substrate's surface, leaving behind a solid deposit of the desired material.

The crucial insight is that CVD is not merely a coating technique; it's a materials synthesis process. Unlike physical methods that simply move a material from a source to a target, CVD uses controlled chemical reactions to build new, highly pure solid materials directly on a surface, one layer of molecules at a time.

The Fundamental CVD Workflow

To understand how CVD works, it's best to break it down into a sequence of distinct steps. Each stage is precisely controlled to achieve the desired material properties.

Step 1: Introducing the Precursors

The process begins by feeding one or more volatile gases, known as precursor gases, into a reaction chamber. These gases contain the chemical elements that will make up the final film.

Often, inert carrier gases like nitrogen or hydrogen are used to dilute the precursors and transport them controllably to the substrate.

Step 2: The Chemical Reaction

The substrate inside the chamber is heated to a specific, critical temperature. This heat provides the necessary energy to trigger a chemical reaction.

The precursor gases either react with each other or decompose directly on the hot surface of the substrate.

Step 3: Deposition and Film Growth

As the chemical reaction occurs, the desired solid material is deposited onto the substrate. This solid material grows in a controlled manner, forming a thin, uniform, and dense film.

The result can be a coating, a powder, or even a single crystal, depending on the process parameters.

Step 4: Removing Byproducts

The chemical reactions create gaseous byproducts in addition to the solid film. These, along with any unreacted precursor and carrier gases, are removed from the chamber through an exhaust system.

This final step is vital for maintaining the purity of the film and controlling the reaction environment.

Key Components of a CVD System

A functional CVD system is an integration of several critical components, each managing a part of the process.

The Reaction Chamber

This is the sealed, often vacuum-controlled environment where the entire deposition process takes place. It's designed to contain the gases and withstand the high temperatures required.

The Substrate and Heating System

The substrate is the object being coated. The heating system provides the energy to drive the chemical reaction and must maintain a precise and uniform temperature across the substrate's surface.

The Gas Delivery System

This network of pipes, valves, and controllers precisely manages the flow rate of precursor and carrier gases into the reaction chamber. Control over the gas mixture is fundamental to controlling the final material's composition.

The Exhaust System

This system removes the gaseous byproducts and unreacted gases from the chamber. It also helps maintain the correct pressure within the chamber, which is often a vacuum to ensure gas purity and flow.

Understanding the Trade-offs: CVD vs. PVD

To truly grasp the significance of CVD, it is helpful to contrast it with its main alternative, Physical Vapor Deposition (PVD).

The Core Distinction: Chemical vs. Physical

CVD builds a film through a chemical reaction on the substrate's surface. New molecules are formed and deposited.

PVD works by a physical process, such as evaporation or sputtering, that transports atoms from a solid source directly onto the substrate without a chemical reaction.

Film Quality and Conformance

Because CVD relies on gases that can flow into every microscopic feature of a surface, it is exceptionally good at producing conformal coatings on complex, three-dimensional shapes.

PVD is often a "line-of-sight" process, which can make it difficult to uniformly coat intricate geometries. However, CVD's chemical nature generally produces films with higher purity and density.

Temperature and Material Constraints

CVD typically requires very high temperatures to drive the necessary chemical reactions. This can limit the types of substrate materials that can be coated without being damaged.

PVD processes can often be performed at much lower temperatures, making them suitable for a wider range of materials, including plastics and other temperature-sensitive substrates.

Making the Right Choice for Your Application

Selecting the correct deposition technique is entirely dependent on your material requirements, substrate limitations, and the geometry of the part.

- If your primary focus is creating exceptionally pure, dense, and uniform films for applications like semiconductors or optics: CVD is often the superior choice due to its chemical reaction-based growth.

- If your primary focus is coating a complex 3D shape with a perfectly consistent thickness: The gas-phase nature of CVD allows it to "coat around corners" far more effectively than most PVD methods.

- If your primary focus is coating a temperature-sensitive material or you need maximum flexibility with metal alloys: PVD is likely more suitable because its lower operating temperatures prevent damage to the underlying substrate.

Ultimately, understanding the CVD process is recognizing the power of controlled chemistry to construct advanced materials from the ground up.

Summary Table:

| Key Aspect | CVD Process Detail |

|---|---|

| Core Mechanism | Chemical reaction of precursor gases on a heated substrate surface. |

| Main Steps | 1. Introduce Precursors → 2. Chemical Reaction → 3. Film Deposition → 4. Remove Byproducts |

| Primary Advantage | Creates highly conformal, dense, and pure coatings on complex 3D shapes |

| Temperature Requirement | Typically high temperatures (can limit substrate choices) |

| Best For | Semiconductor manufacturing, optics, and applications requiring ultra-pure films |

Ready to enhance your materials research with precise thin-film deposition?

KINTEK specializes in advanced lab equipment and consumables for cutting-edge laboratory applications. Our expertise in deposition technologies can help you achieve superior film quality and process efficiency.

Contact our experts today to discuss how our solutions can support your specific CVD or PVD requirements!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the different types of CVD deposition? Choose the Right Method for Your Thin Film Needs

- What is the mechanism of sputter deposition? A Step-by-Step Guide to Thin Film Coating

- Why is vacuum needed for thin film deposition? To Achieve Purity, Uniformity, and Control

- What is the difference between physical vapor deposition and chemical vapor deposition? PVD vs. CVD Explained

- Why do we need vacuum for deposition of thin film? Ensure Purity and Control in Your Lab

- What are the advantages of chemical vapor deposition? Achieve Superior Thin Films for Your Lab

- What is a metal organic chemical vapor deposition? A Guide to High-Purity Thin Film Growth

- What are the catalysts for CNT synthesis? The Key to Controlling Carbon Nanotube Growth