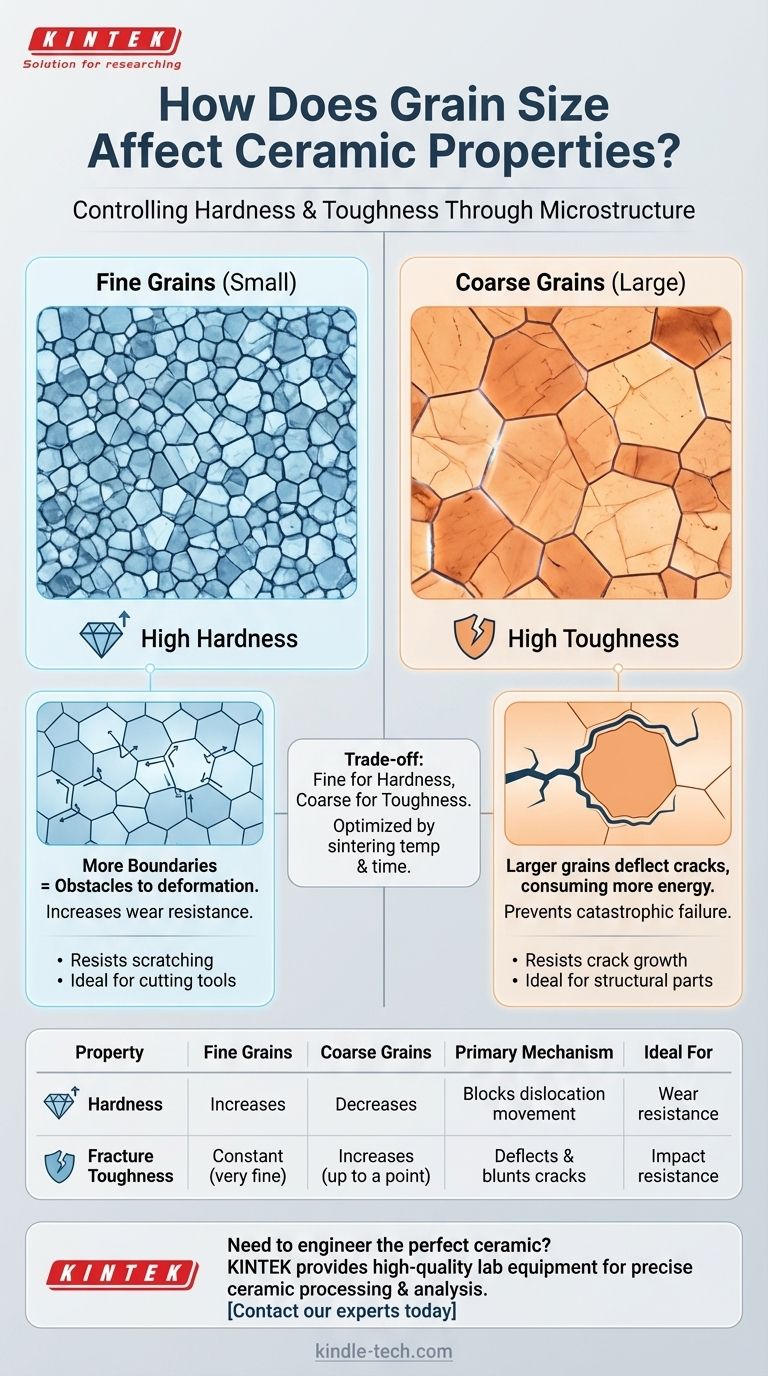

In ceramic engineering, grain size is a primary lever for controlling mechanical properties. Put simply, decreasing a ceramic's grain size generally increases its hardness, making it more resistant to scratching and wear. Conversely, increasing the grain size can, up to a point, improve its fracture toughness, which is its ability to resist the propagation of cracks.

The central principle is that grain boundaries—the interfaces between individual crystal grains—act as obstacles. A higher density of these boundaries (found in fine-grained materials) impedes deformation, increasing hardness, while the path a crack must take around larger grains can dissipate more energy, boosting fracture toughness.

The Role of Grain Boundaries in Hardness

The relationship between grain size and hardness is one of the most fundamental concepts in materials science. It all comes down to the material's internal microstructure.

What Are Grains and Grain Boundaries?

A ceramic material is not a single, uniform block. It is a polycrystalline solid, meaning it's composed of many small, individual crystals called grains.

Where these individual grains meet, they form interfaces known as grain boundaries. These boundaries are regions of atomic mismatch and are critical to the material's overall behavior.

How Grain Boundaries Create Hardness

Hardness is a measure of a material's resistance to localized plastic deformation, such as scratching or indentation. In crystalline materials, this deformation occurs through a process called dislocation movement.

Grain boundaries act as effective barriers to this movement. For a dislocation to pass from one grain to another, it must change its direction, which requires significant energy.

The Impact of Finer Grains

A material with smaller, or finer, grains has a much higher density of grain boundaries within the same volume.

With more barriers packed into the material, dislocation movement is severely restricted. This makes the material much more resistant to deformation, resulting in higher hardness. This is why hardness is observed to decrease as grain size increases.

Unpacking the Fracture Toughness Paradox

While fine grains are good for hardness, the effect on fracture toughness—the ability to resist cracking—is more complex and can seem counterintuitive.

Toughness vs. Hardness

Fracture toughness is not about resisting surface indentation; it's about stopping a crack from growing once it has started. The mechanisms that govern this are different from those that control hardness.

Crack Deflection at Grain Boundaries

When a crack encounters a grain boundary, it can be deflected, blunted, or forced to change its path. This process consumes fracture energy, slowing the crack's propagation.

In a coarser-grained ceramic, a crack may be forced to make a larger, more tortuous deviation to get around a grain. This significant change in direction can dissipate more energy than the many small deviations it would make in a fine-grained material.

Interpreting the Behavior

This explains why fracture toughness can be constant for very fine-grained ceramics and then begin to increase with grain size. As the grains become large enough to effectively alter the crack path, the material's ability to absorb fracture energy improves, leading to higher toughness.

Understanding the Trade-offs

Optimizing a ceramic for a specific application requires balancing these competing properties. There is rarely a single grain size that is perfect for all criteria.

The Hardness vs. Toughness Dilemma

The core trade-off is clear: the fine-grained microstructure that maximizes hardness and wear resistance may not provide the highest possible fracture toughness.

An engineer must decide which property is more critical for the component's survival. A cutting tool may prioritize hardness, while a structural component might require maximum toughness to prevent catastrophic failure.

The Role of Processing

It's important to remember that grain size is not an accident. It is a direct result of the ceramic's processing conditions, primarily the sintering temperature and time.

Higher sintering temperatures or longer holding times allow grains to grow, leading to a coarser microstructure. Careful control over this process is how material scientists engineer the desired properties into a final component.

Making the Right Choice for Your Application

Selecting the optimal grain size is not about finding a single "best" value, but about aligning the material's microstructure with its intended function.

- If your primary focus is wear resistance and surface hardness: Aim for a fine-grained microstructure, as the high density of grain boundaries effectively resists plastic deformation and scratching.

- If your primary focus is fracture toughness and preventing catastrophic failure: Consider a coarser-grained ceramic, as larger grains can promote crack deflection and increase the energy required for a fracture to propagate.

Ultimately, controlling grain size is the key to engineering a ceramic that is perfectly suited to its specific operational demands.

Summary Table:

| Property | Fine Grains (Small) | Coarse Grains (Large) |

|---|---|---|

| Hardness | Increases | Decreases |

| Fracture Toughness | Constant (for very fine) | Increases (up to a point) |

| Primary Mechanism | Grain boundaries block dislocation movement | Larger grains deflect and blunt cracks |

| Ideal For | Wear resistance, cutting tools | Structural components, impact resistance |

Need to engineer the perfect ceramic for your specific requirements?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables necessary for precise ceramic processing and analysis. Whether you're sintering samples to achieve a specific grain size or testing mechanical properties, our solutions help you optimize hardness and toughness for your application.

Contact our experts today to discuss how we can support your laboratory's material science needs and help you develop superior ceramic components.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- High Purity Pure Graphite Crucible for Evaporation

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

People Also Ask

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- Why are PTFE wafer fixtures used after diamond nucleation? Ensure Purity and Protect Fragile Nucleation Layers

- Why is slender PTFE tubing necessary for flow control in multi-channel catalyst aging? Ensure Equal Gas Distribution

- Why is Polytetrafluoroethylene (PTFE) preferred as a lining material for reactors? Ensure Maximum Chemical Resistance

- Why is a PTFE Mold Selected for Preparing Composite Films? Ensure Pure, Damage-Free Results