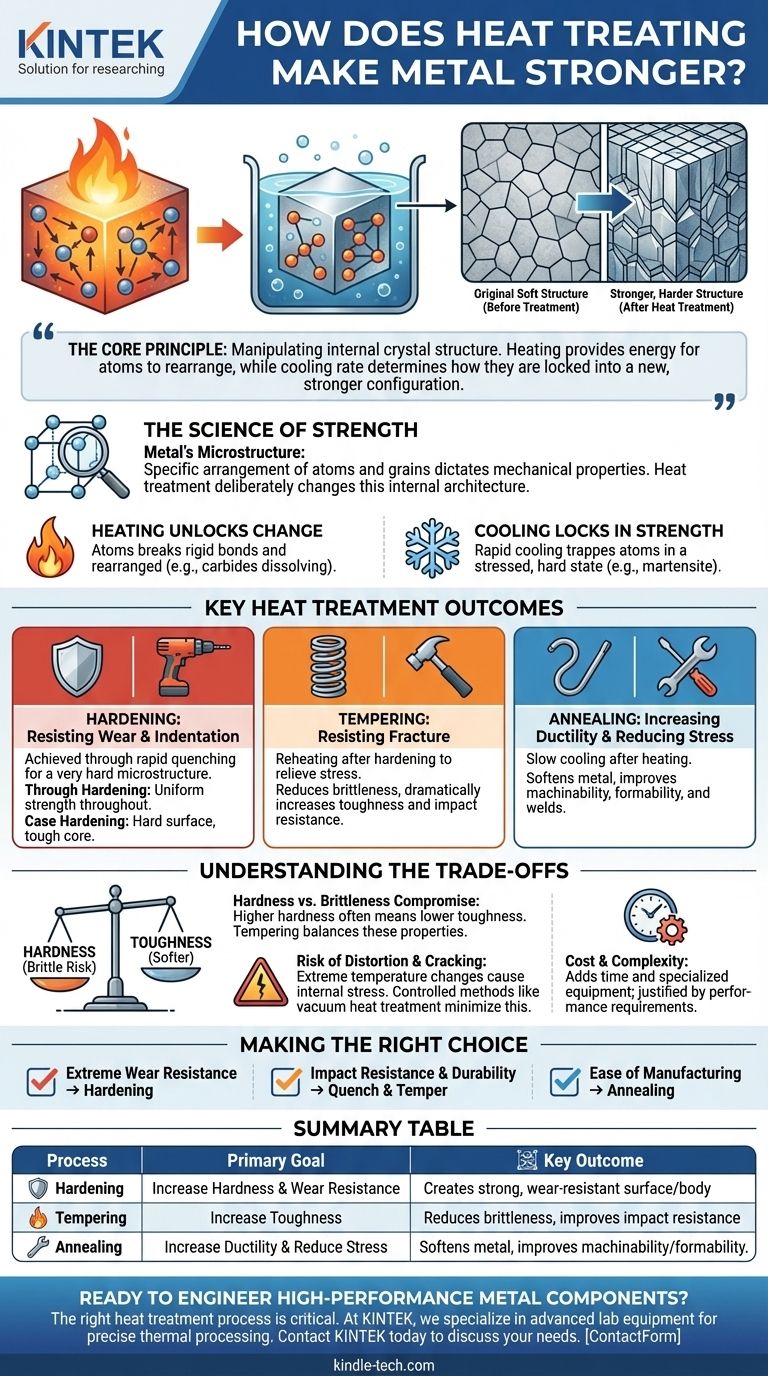

At its core, heat treating makes metal stronger by manipulating its internal crystal structure. This controlled process of heating and cooling rearranges the metal’s atoms into a new configuration, known as a microstructure, that is more resistant to deformation and wear. It is less about adding something to the metal and more about optimizing the structure that is already there.

The fundamental principle is that applying heat gives a metal’s atoms the energy to move, while the rate of cooling determines how they are locked back into place. Rapid cooling traps them in a strong but stressed formation, while slow cooling allows them to settle into a softer, more relaxed state.

The Science of Strength: Atoms and Crystals

To understand heat treatment, you must first understand that a solid piece of metal is not a uniform block. It is a crystalline material composed of countless microscopic grains. The strength of the metal is determined by how these grains and the atoms within them resist being moved or dislocated.

The Role of a Metal's Microstructure

A metal’s microstructure is the specific arrangement of its atoms, crystals, and different phases at a microscopic level. This internal architecture dictates its mechanical properties, including hardness, toughness, and ductility. Heat treatment is the tool used to deliberately change this architecture.

How Heat Unlocks Change

Heating a metal above a critical transformation temperature gives its atoms enough thermal energy to break their rigid bonds. They begin to move and rearrange themselves into a new, more uniform crystal structure. For steel, this involves dissolving hard carbide particles into a solid solution called austenite.

How Cooling Locks in Strength

The cooling phase, or quench, is where the strengthening occurs. By cooling the metal rapidly in a medium like water, oil, or air, the atoms are given no time to return to their original, softer state. Instead, they are trapped in a highly stressed, distorted, and very hard crystal structure, such as martensite in steel. This new structure is extremely resistant to deformation, which we perceive as increased hardness and strength.

Key Heat Treatment Outcomes

"Stronger" is not a single property. Depending on the process, heat treatment can enhance different characteristics to meet specific engineering demands for materials like steel, titanium, and specialized alloys.

Hardening: Resisting Indentation and Wear

Hardening is the most direct way to increase strength. This is achieved through rapid quenching to create a very hard microstructure.

- Through Hardening: Heats and hardens the entire volume of the component, providing uniform strength.

- Case Hardening (Surface Hardening): Selectively hardens only the outer surface of a part, creating a highly wear-resistant shell while leaving the core softer and tougher to absorb impacts.

Toughening: Resisting Fracture

Extreme hardness often comes with a dangerous side effect: brittleness. A process called tempering is used after hardening. The part is reheated to a lower temperature, which relieves some of the internal stress from the quench. This reduces hardness slightly but dramatically increases the material's toughness—its ability to absorb energy and resist fracturing.

Annealing: Increasing Ductility and Reducing Stress

Annealing is essentially the opposite of hardening. After heating, the metal is cooled very slowly. This allows the atoms to rearrange into a soft, stress-free microstructure, making the metal easier to machine, form, or weld.

Understanding the Trade-offs

Heat treatment is not a one-size-fits-all solution; it is a series of compromises between desirable properties. Understanding these trade-offs is critical for successful application.

The Hardness vs. Brittleness Compromise

The primary trade-off is between hardness and toughness. The harder a material becomes, the more brittle it tends to be. A fully hardened, untempered steel component may be extremely resistant to scratches but could shatter like glass if dropped. Tempering is the act of intentionally trading some hardness to gain crucial toughness.

The Risk of Distortion and Cracking

The extreme temperature changes involved in heat treatment induce significant internal stress. This can cause parts to warp, distort, or even crack, especially those with complex geometries or sharp corners. Controlled methods like vacuum heat treatment are used to minimize this by ensuring uniform heating and preventing surface reactions and discoloration.

Cost and Complexity

Heat treatment adds both cost and time to the manufacturing process. It requires specialized furnaces, precise temperature and atmospheric controls, and skilled operators. The decision to heat treat must be justified by a clear performance requirement that cannot be met by the base material alone.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process requires a clear understanding of the component's final application and its most critical performance characteristic.

- If your primary focus is extreme wear resistance: Use through hardening or case hardening to achieve the highest possible surface hardness.

- If your primary focus is impact resistance and durability: Use a quench-and-temper process to create a balance of high strength and good toughness.

- If your primary focus is ease of manufacturing: Use annealing to soften the material, reduce internal stress, and improve its machinability or formability.

Ultimately, heat treatment transforms a standard material into a high-performance component engineered for a specific task.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Hardening | Increase Hardness & Wear Resistance | Creates a strong, wear-resistant surface or body. |

| Tempering | Increase Toughness | Reduces brittleness after hardening, improves impact resistance. |

| Annealing | Increase Ductility & Reduce Stress | Softens metal, improves machinability and formability. |

Ready to engineer high-performance metal components?

The right heat treatment process is critical to achieving the perfect balance of strength, toughness, and durability for your application. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for precise thermal processing.

Whether you are developing new alloys or optimizing existing processes, our expertise and reliable products support your laboratory's success in materials science and manufacturing.

Contact KINTEK today to discuss how our solutions can enhance your heat treatment capabilities and help you achieve superior material properties.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Why are high-temperature closed furnaces and vacuum desiccators essential for pre-treating eutectic salt raw materials?

- What is the purpose of a vacuum system? Achieve Unmatched Process Control and Purity

- What is the specific danger associated with hot argon in bottom-loading vacuum furnaces? Understanding the Invisible Asphyxiation Risk

- Why is a vacuum drying oven necessary for cathode composites? Ensure Battery Safety and Interfacial Performance

- What is the difference between sintering and fusing? Master the Key Thermal Processes for Your Materials

- Does hardening affect dimensions? Master the Metallurgical Changes for Precision Parts

- What is vacuum heat treating? Achieve Superior Metallurgical Purity and Surface Integrity

- What are the advantages and disadvantages of oil as a quenching medium? Achieve Superior Hardening with Minimal Distortion