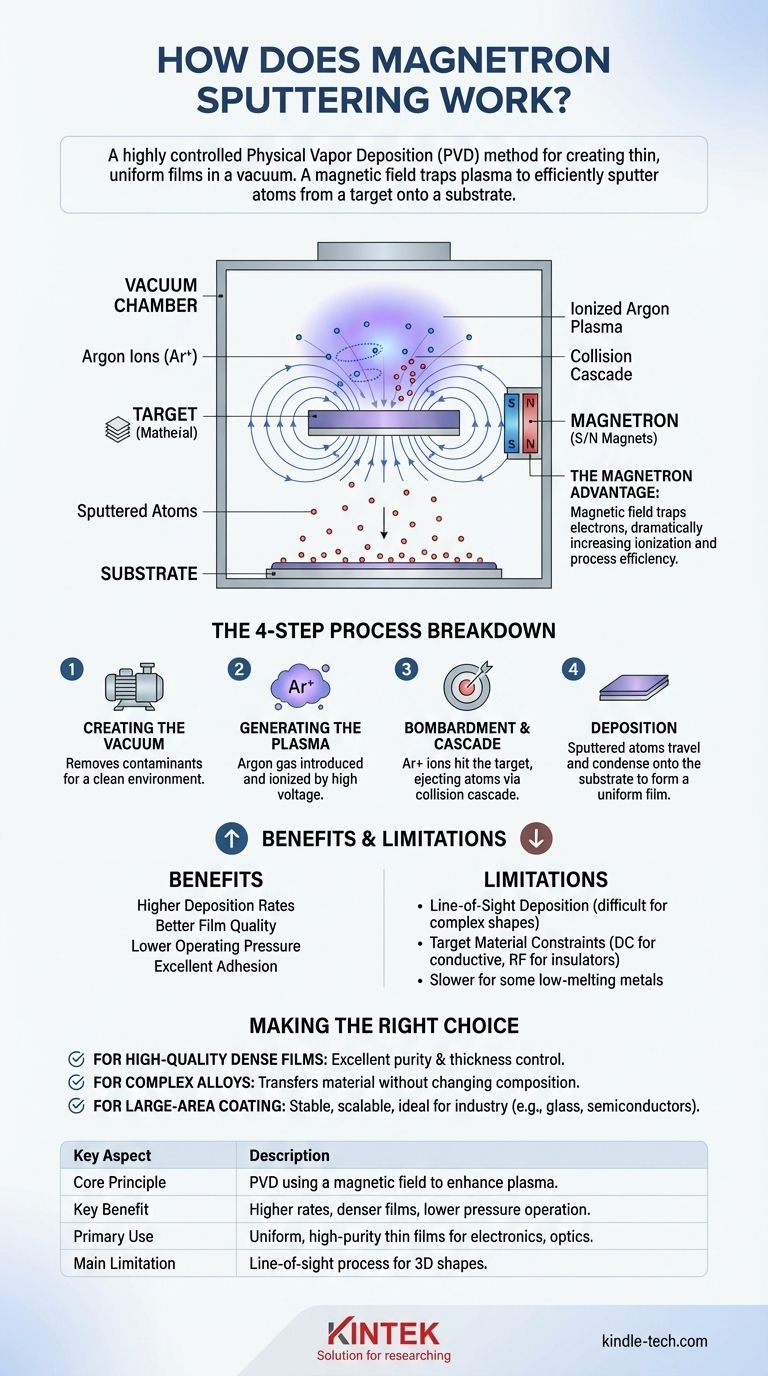

At its core, magnetron sputtering is a highly controlled method of physical vapor deposition (PVD) used to create extremely thin and uniform films of material. The process takes place in a vacuum, where a magnetic field is used to trap a plasma of ionized gas, concentrating it onto a source material called a "target." This intense bombardment knocks atoms off the target, which then travel and condense onto a "substrate," forming the desired coating.

The key takeaway is not just the sputtering itself, but the role of the magnetron. The magnetic field dramatically increases the efficiency of the plasma, leading to higher deposition rates, better film quality, and the ability to operate at lower pressures compared to non-magnetic sputtering.

The Sputtering Process: A Step-by-Step Breakdown

To truly understand magnetron sputtering, we can break it down into four fundamental stages. Each step plays a critical role in the final quality of the thin film.

Step 1: Creating the Vacuum Environment

The entire process occurs within a sealed vacuum chamber.

This is essential to remove atmospheric gases like oxygen and nitrogen, which would otherwise contaminate the film or react with the process. A clean environment ensures the purity of the final coating.

Step 2: Generating the Plasma

A small amount of an inert gas, typically argon (Ar), is introduced into the chamber.

A high voltage is applied between the target material (which acts as the cathode) and the substrate (often near the anode). This electrical field energizes the argon gas, stripping electrons from the atoms and creating a plasma—a glowing, ionized gas cloud of positive argon ions (Ar+) and free electrons.

Step 3: The Bombardment and Collision Cascade

The positively charged argon ions are accelerated by the electric field and slam into the negatively charged target surface with immense kinetic energy.

This impact is not a simple "chip" off the surface. It initiates a collision cascade within the atomic lattice of the target, transferring momentum from the ion to the target atoms. When this cascade reaches the surface, it ejects target atoms if the energy exceeds the material's surface binding energy.

Step 4: Deposition onto the Substrate

The ejected, or "sputtered," atoms travel through the vacuum chamber.

They eventually strike the substrate, which is strategically placed to intercept them. Upon hitting the cooler substrate, the atoms condense and build up, layer by layer, to form a dense and uniform thin film.

The Critical Role of the Magnetron

The process described above is standard sputtering. The "magnetron" is the special component that makes this technique so powerful and widely used.

Trapping Electrons with a Magnetic Field

A set of powerful magnets is placed behind the target. This creates a magnetic field that projects out in front of the target's surface.

This magnetic field is too weak to affect the heavy argon ions, but it is strong enough to trap the much lighter, fast-moving electrons in a spiral path close to the target.

Increasing Ionization Efficiency

By trapping the electrons, the magnetron dramatically increases their path length. Instead of making one or two collisions, they now make hundreds.

Each collision with a neutral argon atom has a chance to create a new argon ion. This results in a much denser, more intense plasma that is concentrated directly over the target, precisely where it is needed most.

The Benefits: Higher Rates and Better Films

This highly efficient plasma leads to a massive increase in the number of ions bombarding the target. This directly translates to a higher deposition rate.

Furthermore, because the process is so efficient, it can be run at lower gas pressures. Lower pressure means the sputtered atoms encounter fewer gas atoms on their way to the substrate, resulting in a purer, denser, and higher-quality film.

Understanding the Trade-offs and Limitations

While powerful, magnetron sputtering is not the solution for every scenario. It is crucial to understand its limitations.

Line-of-Sight Deposition

The sputtered atoms generally travel in straight lines from the target to the substrate. This line-of-sight nature makes it difficult to uniformly coat complex, three-dimensional shapes with sharp corners or undercuts.

Target Material Constraints

The most common setup, DC (Direct Current) sputtering, requires the target material to be electrically conductive. Coating insulating or ceramic materials is possible, but it requires a more complex setup known as RF (Radio Frequency) sputtering.

Deposition Rates for Certain Materials

While much faster than basic sputtering, it may be slower than other PVD methods like thermal evaporation for certain low-melting-point metals.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the desired outcome for your thin film.

- If your primary focus is high-quality, dense films: Magnetron sputtering is an exceptional choice due to its ability to create films with high purity, excellent adhesion, and precise thickness control.

- If your primary focus is coating a complex alloy: Sputtering is ideal because it transfers the material from the target to the substrate without changing its chemical composition (stoichiometry).

- If your primary focus is large-area industrial coating: The stability, control, and scalability of magnetron sputtering make it a go-to technology for applications like architectural glass, semiconductors, and display manufacturing.

By understanding these principles, you can effectively leverage magnetron sputtering to create highly controlled, high-performance thin films for a vast range of applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Physical Vapor Deposition (PVD) using a magnetic field to enhance plasma efficiency. |

| Key Benefit | Higher deposition rates, denser films, and operation at lower pressures. |

| Primary Use | Creating uniform, high-purity thin films for electronics, optics, and coatings. |

| Main Limitation | Line-of-sight process can make coating complex 3D shapes challenging. |

Ready to integrate high-performance thin films into your lab's workflow? KINTEK specializes in providing advanced lab equipment and consumables for precise deposition processes like magnetron sputtering. Our expertise ensures you achieve the high-quality, uniform coatings essential for R&D and production. Contact our experts today to discuss your specific laboratory needs and how we can support your success.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating