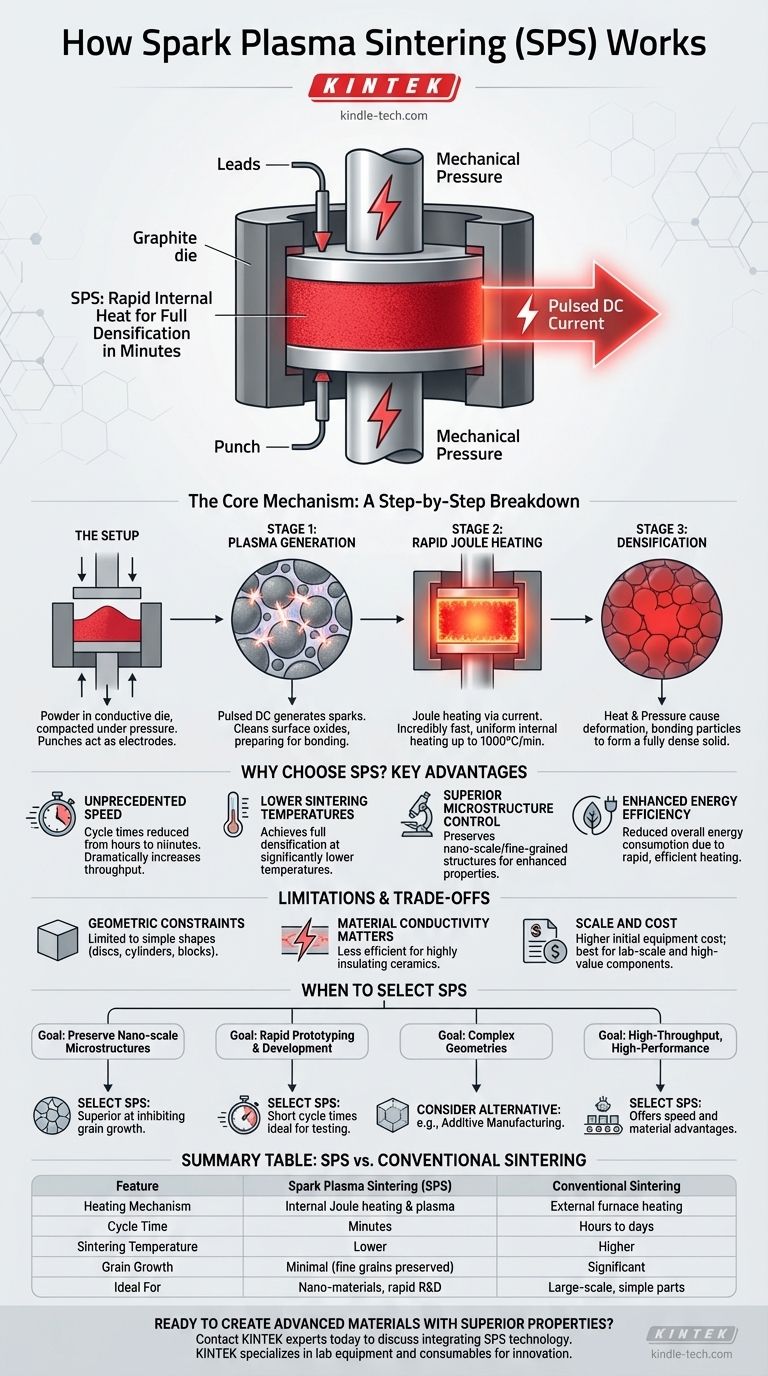

In essence, Spark Plasma Sintering (SPS) is an advanced sintering technique that consolidates powders into a dense solid by simultaneously applying high mechanical pressure and passing a high-power pulsed direct current (DC) through them. Unlike conventional furnaces that heat externally and slowly, SPS uses the powder and its tooling as a heating element, creating rapid, internal heat. This allows for full densification in a matter of minutes rather than hours.

The fundamental advantage of SPS lies in its unique heating mechanism. By using electricity to generate heat directly within the material, it dramatically shortens processing time and lowers the required sintering temperature, which is critical for creating advanced materials with fine-grained microstructures and superior properties.

The Core Mechanism: A Step-by-Step Breakdown

To understand why SPS is so effective, it's useful to break the process down into its distinct stages, which occur in rapid succession.

The Setup: Combining Pressure and Current

First, the raw powder is placed into a conductive die, typically made of graphite. The powder is then compacted between two punches under a uniaxial mechanical load, similar to a standard hot pressing setup.

Crucially, these punches also serve as electrodes, connecting the entire die assembly to a high-power source.

Stage 1: Plasma Generation and Surface Cleaning

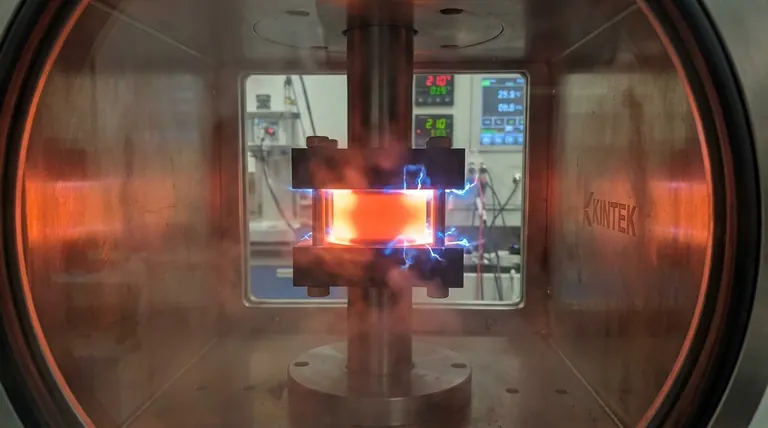

When the pulsed DC current is first applied, the microscopic gaps between powder particles can generate sparks or momentary plasma discharges.

This initial energy burst is believed to be vital for the process. It helps to burn away any surface oxides or contaminant films on the powder particles, creating pristine surfaces that are ready to bond.

Stage 2: Rapid Joule Heating

Following the initial sparking, the primary heating mechanism takes over: Joule heating. This is the effect where heat is generated as an electrical current passes through a resistive material.

The current flows through the conductive graphite die and, if the powder is also conductive, through the powder compact itself. This dual heating (external from the die and internal from the powder) creates incredibly fast and uniform heating, with rates that can reach up to 1000°C/min.

Stage 3: Densification and Plastic Deformation

The combination of intense, rapid heat and constant mechanical pressure forces the powder particles to soften and deform. This plastic deformation allows the particles to bond together, rapidly eliminating the empty spaces (porosity) between them and forming a fully dense, solid part.

Why Choose SPS? The Key Advantages

The unique mechanism of SPS unlocks several significant benefits that are unattainable with traditional furnace-based sintering.

Unprecedented Speed

The most obvious advantage is speed. By heating the material directly, SPS reduces cycle times from many hours to just a few minutes. This dramatically increases throughput for research and production.

Lower Sintering Temperatures

Because the electrical current and plasma effects enhance particle-to-particle bonding, SPS can achieve full densification at much lower temperatures—often several hundred degrees Celsius lower than conventional methods require.

Superior Microstructure Control

This is arguably the most important technical benefit. In materials science, smaller grain sizes often lead to superior mechanical properties like strength and hardness.

Because SPS uses lower temperatures and extremely short processing times, it gives the material's grains very little time to grow. This allows it to preserve the nano-scale or fine-grained structures of advanced powders, resulting in higher-performance materials.

Enhanced Energy Efficiency

The combination of high heating rates, short cycle times, and lower temperatures means the overall energy consumption is significantly reduced compared to running a large furnace for half a day, making SPS a more cost-effective and sustainable process.

Understanding the Limitations and Trade-offs

While powerful, SPS is not a universal solution. Its methodology brings inherent trade-offs that are critical to understand.

Geometric Constraints

The use of a rigid die and uniaxial pressure means SPS is primarily suited for producing simple geometries, such as discs, cylinders, and rectangular blocks. Creating complex, near-net-shape parts is extremely difficult.

Material Conductivity Matters

The efficiency and uniformity of heating are highest in electrically conductive materials. For highly insulating ceramics, the heating occurs primarily through the graphite die, making it less direct and potentially leading to temperature gradients between the surface and the core of the sample.

Scale and Cost

SPS equipment is specialized and more expensive than a conventional furnace. While excellent for lab-scale development and production of high-value components, it can be less cost-effective for mass production of large, simple parts where a traditional furnace would suffice.

When to Select Spark Plasma Sintering

The decision to use SPS hinges on your specific material goals and performance requirements.

- If your primary focus is preserving nano-scale or fine-grained microstructures: SPS is the superior choice because its speed and lower temperatures are uniquely effective at inhibiting grain growth.

- If your primary focus is rapid material development and prototyping: The short cycle times of SPS make it ideal for quickly consolidating and testing novel powder compositions.

- If your primary focus is producing geometrically complex parts: You should consider alternative methods like additive manufacturing or powder injection molding, as SPS is limited to simple shapes.

- If your primary focus is high-throughput production of high-performance materials: SPS offers significant advantages in speed and final material properties over conventional furnace-based sintering for suitable geometries.

Ultimately, Spark Plasma Sintering provides an unparalleled level of control over the densification process, enabling the creation of advanced materials that are simply not possible with traditional techniques.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Mechanism | Internal Joule heating & plasma | External furnace heating |

| Cycle Time | Minutes | Hours to days |

| Sintering Temperature | Lower | Higher |

| Grain Growth | Minimal (fine grains preserved) | Significant |

| Ideal For | Nano-materials, rapid R&D | Large-scale, simple parts |

Ready to create advanced materials with superior properties?

Spark Plasma Sintering is a powerful technique for developing high-performance materials with fine-grained microstructures, rapid prototyping, and energy-efficient production. If your lab works with advanced ceramics, metals, or composites, KINTEK's expertise in lab equipment can help you integrate SPS technology to accelerate your research and development.

Contact our experts today via our Contact Form to discuss how SPS can benefit your specific application. KINTEK specializes in providing the lab equipment and consumables you need to innovate.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Graphite Vacuum Continuous Graphitization Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What specific processing conditions does a vacuum hot pressing furnace provide for the sintering of FeCrAl composites?

- How does the Hot Isostatic Pressing (HIP) process work? Enhance Material Density and Integrity

- Why is Graphite Paper utilized during the hot-pressing of AZ31 composite sheets? Optimize Your Metal Fabrication

- What is the core function of a Vacuum Hot Pressing (VHP) furnace? Achieve 99.7% Density in Ruthenium Targets

- Why use vacuum in hot-press sintering for boron carbide? Achieve Superior Density and Material Purity

- How does the temperature control system of a vacuum hot press maintain the nanometer-scale microstructure of copper?

- What is the hot pressing method of sintering? A Guide to High-Density Material Fabrication

- Why is a vacuum hot pressing sintering furnace required for Ni-Cr-Co-Ti-V alloys? Achieve High Density & Purity