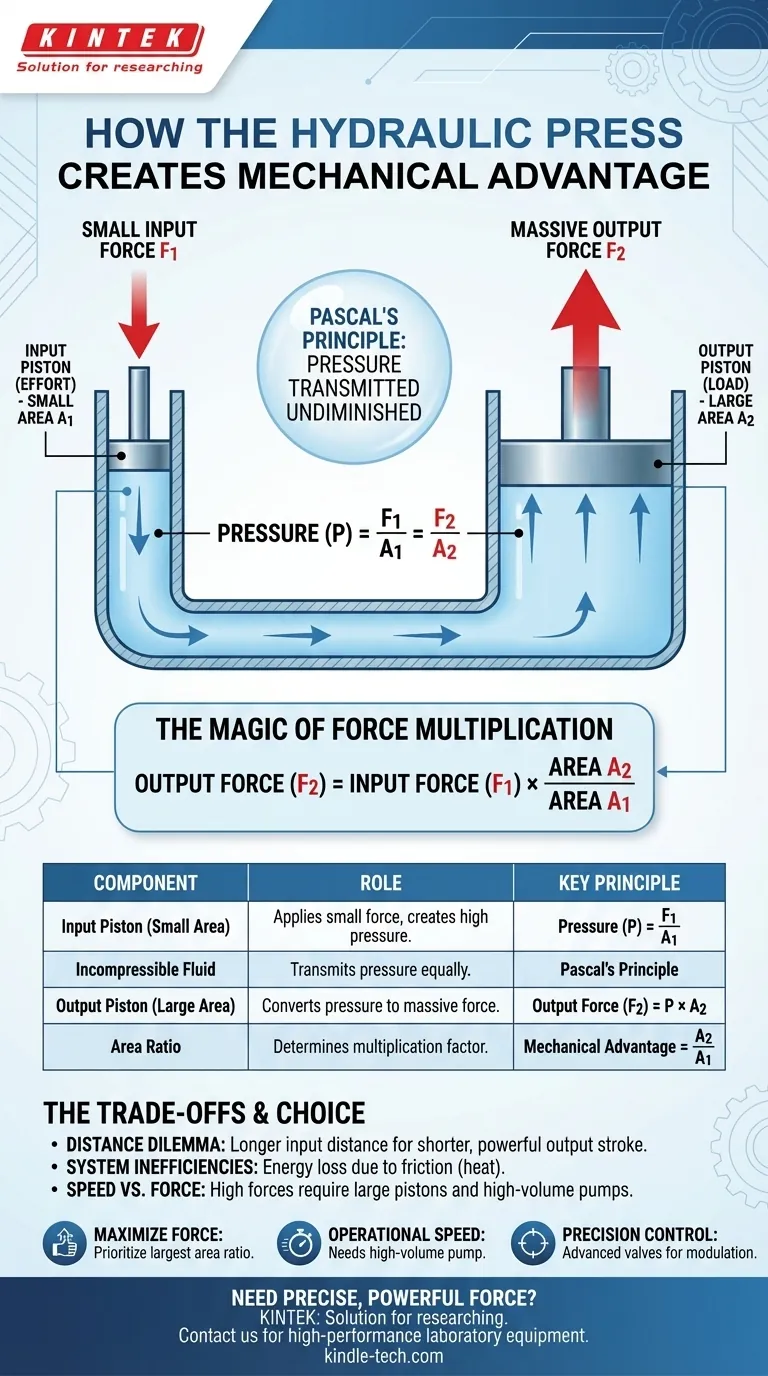

The fundamental principle is force multiplication. A hydraulic press achieves a massive mechanical advantage by applying a small force over a small area, which transmits pressure through an incompressible fluid to a large area, resulting in a much larger output force. This entire process is governed by Pascal's Principle.

The core insight is that pressure within a confined fluid is constant. By manipulating the surface area of the pistons that interact with this fluid, a hydraulic press converts a small input force into a massive output force, trading a longer input distance for a shorter, more powerful output stroke.

The Core Principle: Pascal's Law

The operation of a hydraulic press is a direct application of a fundamental law of fluid mechanics known as Pascal's Principle. Understanding this concept is key to understanding the entire system.

What is Pressure?

First, it's critical to distinguish between force and pressure. Force is a push or a pull, while pressure is defined as force distributed over a specific area (Pressure = Force / Area).

A small force concentrated on a tiny area can create immense pressure. This is the first step in the hydraulic process.

The Role of an Incompressible Fluid

Hydraulic systems use a fluid, typically oil, that is nearly incompressible. This means that when pressure is applied, the fluid's volume does not change.

Because it doesn't compress, the fluid acts as a perfect medium to transmit pressure from one point to another within the system.

Equal Pressure, Unequal Force

Pascal's Principle states that pressure applied to a confined, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

This means the pressure at the small input piston is the exact same as the pressure at the large output piston. Since Pressure = Force / Area, if the pressure is equal on both sides, the force must be proportional to the area.

Anatomy of the Force Multiplication

A simple hydraulic press consists of two primary components connected by a fluid-filled pipe: the input piston and the output piston.

The Input Piston (Effort)

The process begins at the input piston, which has a small surface area (let's call it A1). A small force (F1) is applied to this piston.

This creates a pressure within the fluid: P = F1 / A1.

The Output Piston (Load)

This pressure P is transmitted through the fluid to the output piston, which has a much larger surface area (A2).

Because the pressure is the same, the resulting output force (F2) is F2 = P * A2. By substituting our first equation, we get F2 = (F1 / A1) * A2.

This simple formula reveals the magic: the output force is multiplied by the ratio of the areas of the two pistons. If the output piston has an area 100 times greater than the input piston, the output force will be 100 times greater than the input force.

Understanding the Trade-offs

While hydraulic presses seem to create force from nothing, they operate under the fundamental laws of conservation of energy. This introduces critical trade-offs.

The Distance Dilemma

Energy, or work, is defined as Force x Distance. Since the system cannot create energy, the work done on the input side must equal the work done on the output side.

To generate a massive output force over a short distance, the small input piston must be moved a much longer distance. You are trading distance for force.

System Inefficiencies

In a perfect theoretical model, the energy transfer is 100% efficient. In the real world, this is not the case.

Friction between the pistons and their cylinders, as well as friction within the fluid itself, results in some energy loss, typically as heat.

Speed vs. Force

The speed of the output piston is determined by the volume of fluid that can be pumped into its cylinder.

Achieving extremely high forces often requires a very large output piston, which in turn requires a large volume of fluid to move. This is why high-force presses are often much slower than mechanical presses.

Making the Right Choice for Your Application

The elegance of a hydraulic system lies in its ability to be tailored to specific goals through the manipulation of a few key variables.

- If your primary focus is maximizing force: Prioritize the largest possible ratio between the output piston's area and the input piston's area.

- If your primary focus is operational speed: You need a high-volume pump capable of moving a large amount of fluid quickly to fill the output cylinder.

- If your primary focus is precision and control: The design of the hydraulic valves and control system is paramount for modulating pressure and flow rate accurately.

Ultimately, the hydraulic press is a masterclass in fluid dynamics, providing a reliable and controllable method for immense force multiplication.

Summary Table:

| Component | Role in Force Multiplication | Key Principle |

|---|---|---|

| Input Piston (Small Area) | Applies a small force to create high pressure in the fluid. | Pressure (P) = Force (F1) / Area (A1) |

| Incompressible Fluid | Transmits the applied pressure undiminished throughout the system. | Pascal's Principle |

| Output Piston (Large Area) | Converts the fluid pressure into a massively amplified output force. | Output Force (F2) = P × A2 |

| Area Ratio | Determines the multiplication factor. | Mechanical Advantage = A2 / A1 |

Need precise, powerful force for your lab or production process?

At KINTEK, we specialize in high-performance laboratory equipment, including hydraulic presses designed for reliability and exacting control. Whether you're in materials testing, sample preparation, or R&D, our solutions deliver the mechanical advantage you need.

Let's discuss how a KINTEK hydraulic press can enhance your workflow. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis