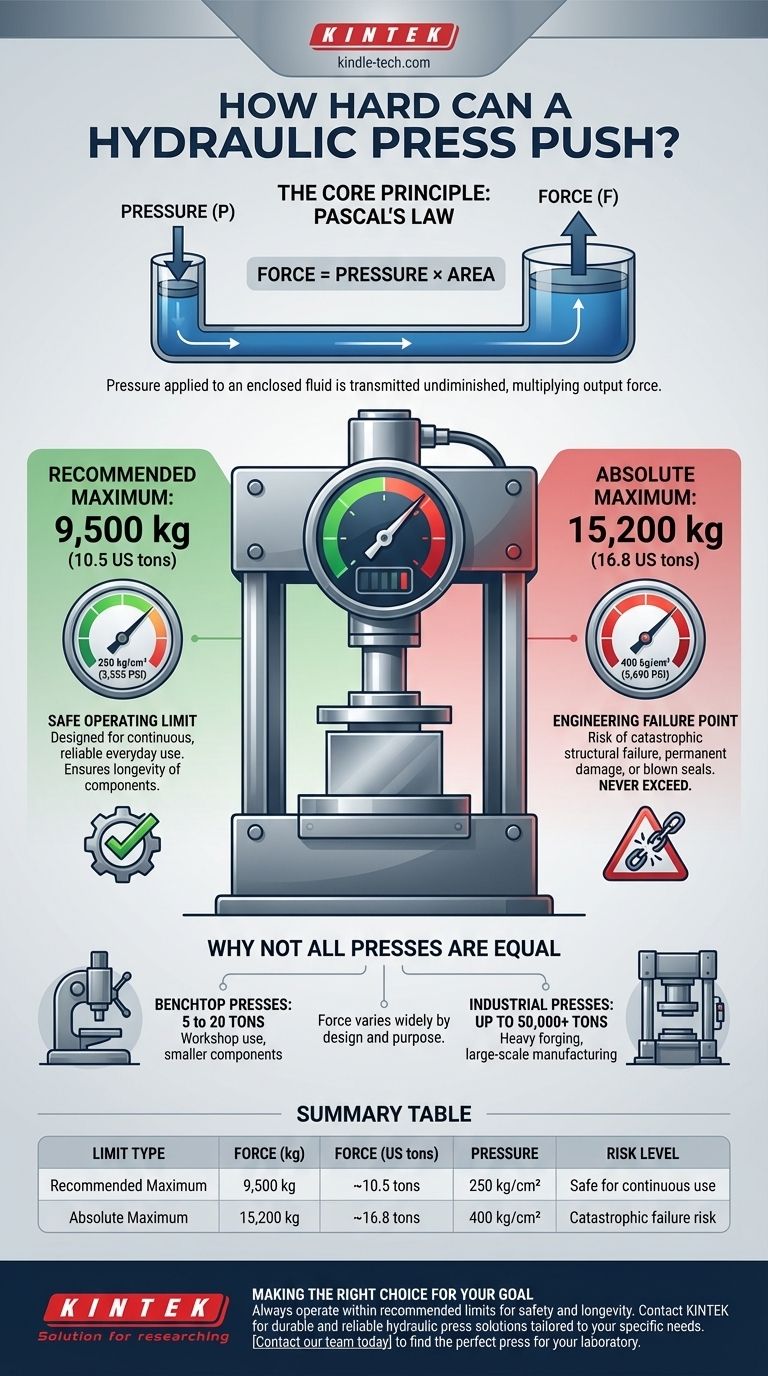

The maximum force a specific hydraulic press can exert is defined by two key limits: a recommended maximum and an absolute maximum. For the press in question, the recommended limit is 9,500 kg (approximately 10.5 US tons) of force, while the absolute structural limit is 15,200 kg (approximately 16.8 US tons). Exceeding the recommended limit introduces risk, while exceeding the absolute limit invites catastrophic failure.

The "how hard" of a hydraulic press is not a single number, but a result of two interconnected factors: the hydraulic pressure the system can generate and the surface area of the piston it pushes against. Understanding this relationship is the key to operating any press safely and effectively.

The Core Principle: Force from Pressure

A hydraulic press operates on a fundamental principle of fluid dynamics known as Pascal's Law. This law states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

Pressure vs. Force: The Key Distinction

It is critical to distinguish between pressure and force. Pressure is the amount of force applied over a specific area, often measured in pounds per square inch (PSI) or kilograms per square centimeter (kg/cm²).

Force is the total pushing power of the press, measured in pounds, kilograms, or tons. The output force is the system's hydraulic pressure multiplied by the surface area of the main ram or piston.

How Pressure Creates Immense Force

A hydraulic pump generates pressure, for example, 250 kg/cm² (about 3,555 PSI). This pressure then acts on a large piston.

If that piston has a surface area of 38 cm² (a diameter of roughly 7 cm or 2.75 inches), the resulting force is calculated simply: 250 kg/cm² × 38 cm² = 9,500 kg of force. This is how a small, manageable pressure generates an immense output force.

Understanding the Limits: Recommended vs. Absolute

The two limits provided—recommended and absolute—are not arbitrary. They represent critical engineering and safety thresholds for the machine's components.

The 'Recommended' Maximum (9,500 kg)

This is the safe operating limit for continuous, everyday use. Operating at or below this level ensures the press functions without undue stress on its frame, seals, and hydraulic lines.

Think of this as the sustainable cruising speed of a car. It's the level at which the machine can perform its work reliably for its intended lifespan. The corresponding pressure is 250 kg/cm².

The 'Absolute' Maximum (15,200 kg)

This is the engineering failure point. Pushing the press to this level, which corresponds to a hydraulic pressure of 400 kg/cm² (about 5,690 PSI), takes the machine beyond its designed operational capacity.

Operating here, even briefly, risks permanently stretching the steel frame, blowing hydraulic seals, or causing a catastrophic structural failure. This limit is not a target; it is a boundary that should never be crossed.

Why Not All Presses Are Equal

The force a press can generate varies enormously based on its design, size, and intended purpose. The figures discussed here are for one specific, likely medium-duty, press.

Benchtop vs. Industrial Presses

A small benchtop press used in a workshop might generate 5 to 20 tons of force. In contrast, massive industrial forging presses can generate forces exceeding 50,000 tons.

The core principle remains the same, but the scale of the components—pump pressure, cylinder size, and especially frame construction—is vastly different.

The Critical Role of the Frame

The force generated by the hydraulic ram must be opposed by an equal force from the press's frame. If the frame is not strong enough to withstand the load, it will bend, crack, or fail long before the hydraulics reach their maximum pressure.

A press's true capability is therefore dictated by its weakest link, which is often the structural C-frame or H-frame.

Making the Right Choice for Your Goal

Understanding these principles allows you to select and use a hydraulic press safely and effectively.

- If your primary focus is safety and machine longevity: Always operate at or below the manufacturer's recommended maximum force and pressure ratings.

- If you are assessing a press of unknown capacity: Look for a pressure gauge. The press's force can be estimated by calculating the ram's surface area (Area = π × radius²) and multiplying it by the pressure reading.

- If you are choosing a press for a specific task: Select a press where your required force falls around 50-75% of its recommended capacity, not its absolute maximum.

Ultimately, a hydraulic press is a tool that multiplies force, and knowing its operational limits is fundamental to using that power correctly.

Summary Table:

| Limit Type | Force (kg) | Force (US tons) | Hydraulic Pressure (kg/cm²) | Risk Level |

|---|---|---|---|---|

| Recommended Maximum | 9,500 kg | ~10.5 tons | 250 kg/cm² | Safe for continuous use |

| Absolute Maximum | 15,200 kg | ~16.8 tons | 400 kg/cm² | Risk of catastrophic failure |

Need a hydraulic press you can trust for your lab or workshop?

Choosing the right equipment is critical for safety and achieving consistent results. At KINTEK, we specialize in supplying durable and reliable lab equipment, including hydraulic presses designed for a range of applications.

Our experts can help you select a press that meets your specific force requirements while ensuring you operate safely within recommended limits. Don't risk equipment failure or compromised results.

Contact our team today to discuss your needs and find the perfect hydraulic press solution for your laboratory.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How does a laboratory manual hydraulic press facilitate the FT-IR characterization of catalysts? Master Sample Prep.

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging