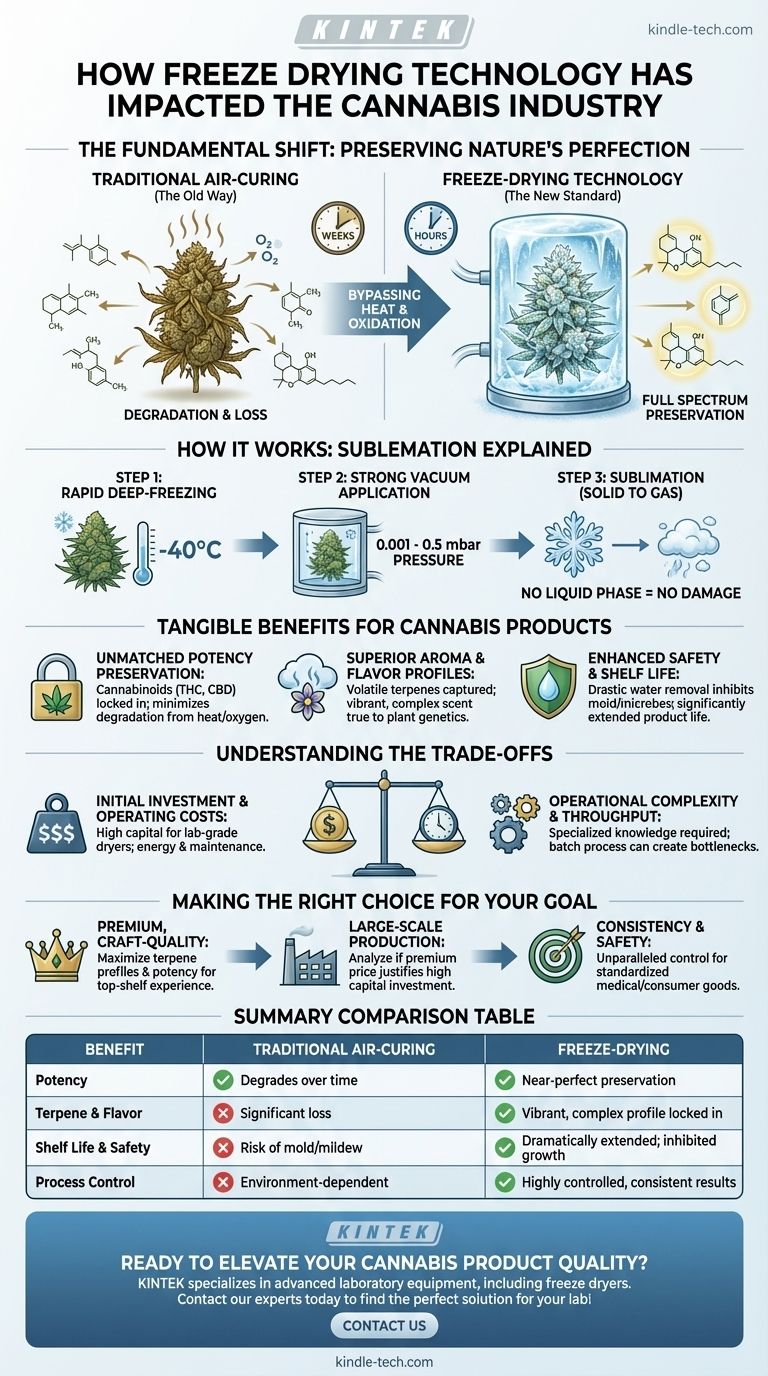

At its core, freeze-drying technology has fundamentally changed the cannabis industry by enabling producers to preserve the plant's chemical profile with unprecedented fidelity. Unlike traditional air-curing, which degrades sensitive compounds over time, freeze-drying locks in the full spectrum of cannabinoids and terpenes at the moment of harvest, resulting in a higher quality, more potent, and more stable final product.

The critical shift is from viewing drying as a necessary evil to leveraging it as a preservation technique. Freeze-drying bypasses the damaging effects of heat and oxidation, allowing producers to deliver a product that is a near-perfect snapshot of the living plant.

How Freeze Drying Works: A Shift from Air to Sublimation

To understand the impact of freeze-drying, we must first recognize the limitations of the method it replaces. The technology's value comes from solving the core problems inherent in traditional curing.

The Problem with Traditional Curing

Traditional methods involve hanging plants to air-dry for weeks. This prolonged exposure to oxygen and fluctuating temperatures inevitably causes the degradation of valuable, volatile compounds like terpenes (which govern aroma and flavor) and cannabinoids (which determine potency and effect).

The Science of Sublimation

Freeze-drying is a multi-stage process that leverages a physical principle called sublimation. First, the cannabis is rapidly deep-frozen at normal pressure.

Next, it is placed under a strong vacuum, typically at absolute pressures between 0.001 and 0.5 millibar. This environment allows the frozen water to transition directly from a solid (ice) to a gas (vapor) without ever becoming a liquid.

Bypassing the Damaging Liquid Phase

This direct solid-to-gas transition is the key. By avoiding liquid water and the high temperatures needed for evaporation, the process masterfully removes moisture without damaging the plant's delicate cellular structure or its chemical contents.

The Tangible Benefits for Cannabis Products

The scientific advantages of freeze-drying translate directly into measurable improvements in the final product, setting a new standard for quality and consistency.

Unmatched Preservation of Potency

Cannabinoids are sensitive to heat and oxidation. By drying the plant in a cold, controlled vacuum, freeze-drying technology minimizes the degradation of THC, CBD, and other key compounds, ensuring the final product is as potent as the day it was harvested.

Superior Aroma and Flavor Profiles

Terpenes are extremely volatile and are often the first compounds lost during a slow, traditional cure. Freeze-drying locks these aromatic molecules in place, resulting in a product with a significantly more vibrant and complex flavor and scent profile that truly represents the plant's genetics.

Enhanced Product Safety and Shelf Life

The process removes water far more thoroughly than air-drying. This drastic reduction in water content effectively inhibits the growth of mold, mildew, and other microbes, leading to a safer product with a dramatically extended shelf life.

Understanding the Trade-offs

While the benefits are significant, adopting freeze-drying technology is not without its challenges. Objectivity requires acknowledging the practical and financial considerations.

Initial Investment and Operating Costs

Laboratory-grade freeze dryers represent a substantial capital investment compared to the minimal infrastructure required for traditional air-curing. The energy consumption and maintenance of these complex machines also contribute to higher operating costs.

Operational Complexity and Throughput

Freeze-drying is a technical process that requires specialized knowledge to operate correctly. Furthermore, the batch-based nature of the process can create bottlenecks and may present challenges for producers operating at a massive industrial scale compared to large, simple drying rooms.

Making the Right Choice for Your Goal

The decision to adopt freeze-drying technology depends entirely on your primary business objectives.

- If your primary focus is premium, craft-quality products: Freeze-drying is the superior choice for preserving unique terpene profiles and maximizing potency for a top-shelf consumer experience.

- If your primary focus is large-scale, cost-sensitive production: The high capital cost of freeze-drying requires a careful analysis to determine if the premium price point of the final product justifies the investment over traditional methods.

- If your primary focus is product consistency and safety: Freeze-drying offers unparalleled control, removing environmental variables to produce a stable, safe, and replicable product ideal for medical or standardized consumer goods.

Ultimately, freeze-drying empowers producers to close the gap between the living plant and the finished product.

Summary Table:

| Benefit | Traditional Air-Curing | Freeze-Drying |

|---|---|---|

| Potency Preservation | Degrades over time | Near-perfect preservation |

| Terpene & Flavor | Significant loss | Vibrant, complex profile locked in |

| Shelf Life & Safety | Risk of mold/mildew | Dramatically extended; microbial growth inhibited |

| Process Control | Environment-dependent | Highly controlled, consistent results |

Ready to elevate your cannabis product quality with precision freeze-drying? KINTEK specializes in advanced laboratory equipment, including freeze dryers designed for the demanding needs of the cannabis industry. Our solutions help you preserve the full spectrum of cannabinoids and terpenes, ensuring a premium, potent, and stable final product that stands out in the market. Contact our experts today to find the perfect freeze-drying solution for your lab!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does freeze-drying play in biotechnology? Preserving Biological Integrity for Long-Term Stability

- What can I use instead of rotavap? Find the Perfect Solvent Removal Tool for Your Lab

- Which industries commonly use lab freeze dryers? Preserve Sensitive Materials with Lyophilization

- Where are evaporators used in food industry? Concentrate Products & Reduce Costs

- Does THC evaporate over time? The Truth About Potency Loss and Preservation