At their core, lab freeze dryers are indispensable tools in any field requiring the gentle preservation of sensitive biological or chemical materials. The industries that rely on this technology most heavily include pharmaceuticals, biotechnology, food science, and advanced scientific research. The process, known as lyophilization, removes water from a frozen substance without passing through a liquid phase, thereby preserving the material's delicate structure, potency, and long-term stability.

The fundamental value of a lab freeze dryer isn't just about drying; it's about preserving integrity. Industries use it when the biological activity, chemical structure, or physical form of a substance must be perfectly maintained after water removal, enabling stable, long-term storage.

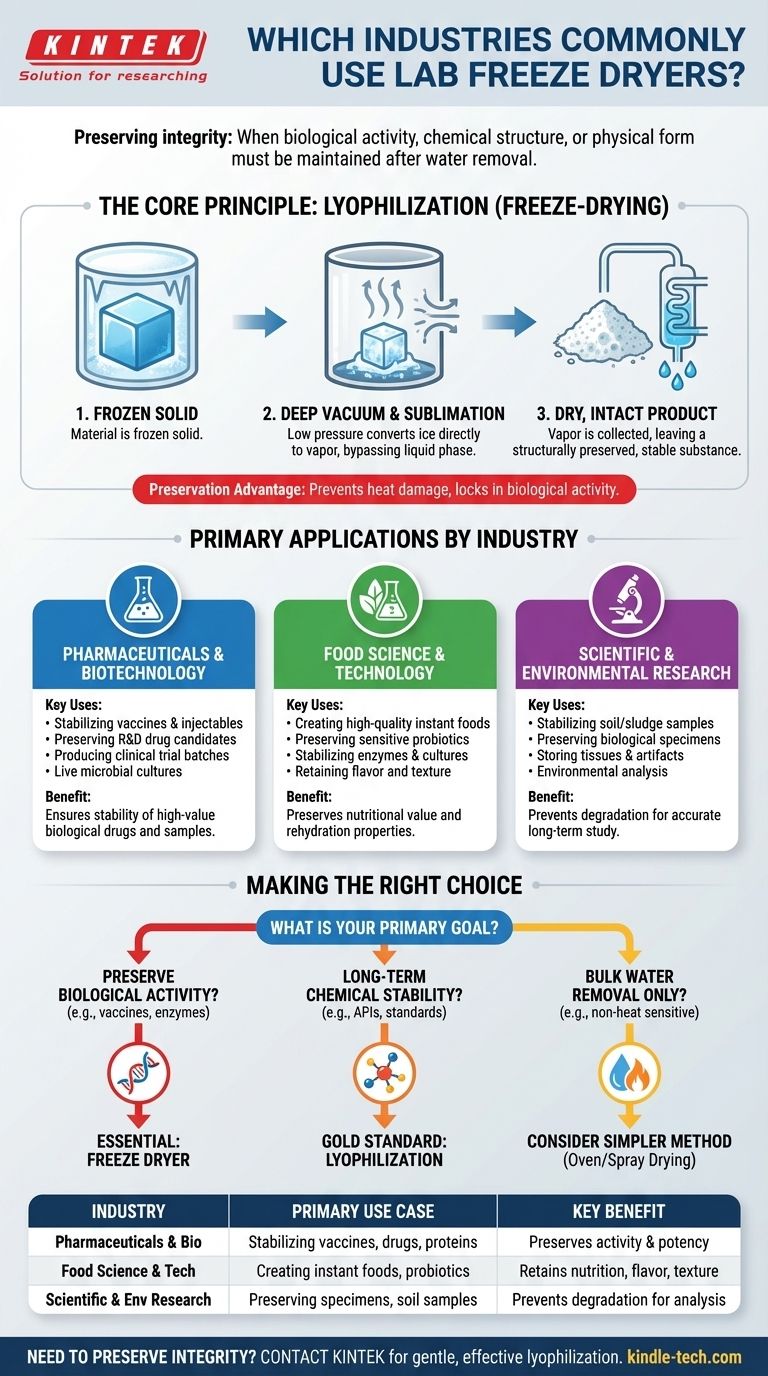

The Core Principle: Why Lyophilization is Critical

Lyophilization, or freeze-drying, is a fundamentally different process than simply heating a substance to evaporate water. Understanding this difference is key to seeing its value.

From Frozen Solid to Dry Powder

The process involves three main steps. First, the material is frozen solid. Next, it is placed under a deep vacuum. Finally, a small amount of energy is added, causing the frozen water to transform directly into vapor in a process called sublimation.

This vapor is then collected on a condenser, leaving behind a dry, structurally intact, and lightweight version of the original substance.

The Preservation Advantage

Standard heat-based drying can destroy or denature heat-sensitive materials like proteins, bacteria, or complex chemical compounds. Lyophilization avoids this damage entirely.

By keeping the material frozen throughout the drying process, its biological activity and chemical structure are locked in place and perfectly preserved.

Primary Applications by Industry

While the principle is the same, different industries leverage freeze-drying to solve distinct and critical challenges.

Pharmaceuticals & Biotechnology

This is the cornerstone application for lab freeze dryers. The stability of high-value biological drugs is paramount, and lyophilization is often the only way to achieve it.

Key uses include preserving the stability of new drug candidates during research and development (R&D) and producing stable batches of investigational drugs for clinical trials. It's also used in small-scale manufacturing for commercial products like vaccines, injectable drugs, proteins, and live microbial cultures.

Food Science & Technology

In the food industry, lab freeze dryers are used to preserve the nutritional value, flavor, and texture of ingredients far more effectively than other drying methods.

This is essential for creating high-quality instant foods, preserving sensitive probiotics for supplements, and stabilizing enzymes or cultures used in food production. The result is a lightweight product that rehydrates quickly while retaining its original characteristics.

Scientific and Environmental Research

Researchers across many disciplines rely on freeze-drying to stabilize samples for later analysis. This is crucial in environmental studies, where water must be removed from soil or sludge samples without altering their chemical composition.

It is also used to preserve biological specimens, tissues, and archaeological artifacts, preventing degradation and allowing for detailed study long after collection.

Understanding the Trade-offs

While powerful, lyophilization is not the default solution for all drying needs. It involves specific costs and benefits that make it suitable for particular applications.

The Cost of Precision

Freeze-drying is a slow, energy-intensive process. The equipment required to achieve the necessary low temperatures and high vacuum is complex and represents a significant capital investment.

Compared to simple oven or air drying, it is a more expensive and time-consuming method of water removal.

When It Becomes Non-Negotiable

Despite the costs, there is often no viable alternative for high-value, heat-sensitive materials. The potential financial and scientific loss from a degraded batch of a developmental vaccine or a unique biological sample far outweighs the operational cost of freeze-drying.

It is a necessary investment when the integrity of the final product is the highest priority.

Making the Right Choice for Your Application

To determine if a lab freeze dryer is the right tool, consider your ultimate goal.

- If your primary focus is preserving biological activity: A freeze dryer is essential for materials like vaccines, proteins, enzymes, or live bacterial cultures.

- If your primary focus is long-term chemical stability: Lyophilization is the gold standard for creating stable, easily stored active pharmaceutical ingredients (APIs) or sensitive chemical standards.

- If your primary focus is simply water removal for bulk materials: A simpler method like oven drying or spray drying is likely more cost-effective, provided the material is not sensitive to heat.

Ultimately, choosing a freeze dryer is a decision to prioritize the integrity and long-term viability of your material above all else.

Summary Table:

| Industry | Primary Use Case | Key Benefit |

|---|---|---|

| Pharmaceuticals & Biotechnology | Stabilizing vaccines, injectable drugs, proteins | Preserves biological activity and potency |

| Food Science & Technology | Creating instant foods, preserving probiotics, stabilizing enzymes | Retains nutritional value, flavor, and texture |

| Scientific & Environmental Research | Preserving biological specimens, stabilizing soil/sludge samples | Prevents degradation for accurate long-term analysis |

Need to preserve the integrity of your sensitive materials? A lab freeze dryer from KINTEK is the solution for gentle, effective lyophilization. Our equipment is designed to meet the precise demands of pharmaceutical, biotech, food science, and research laboratories, ensuring your valuable samples and products maintain their structure and stability.

Contact KINTEK today to discuss how our freeze dryers can enhance your lab's capabilities and protect your most critical work.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures