In short, freeze drying is a critical process used in biotechnology and chemistry to gently remove water from sensitive materials. By freezing a substance and then turning the ice directly into vapor under a vacuum, it preserves the structure, activity, and viability of products like vaccines, enzymes, and high-purity chemical compounds for long-term storage or analysis.

The fundamental value of freeze drying, or lyophilization, is its ability to achieve dehydration without the damaging effects of heat. This makes it the essential method for preserving the integrity of fragile biological materials and purifying delicate chemical substances.

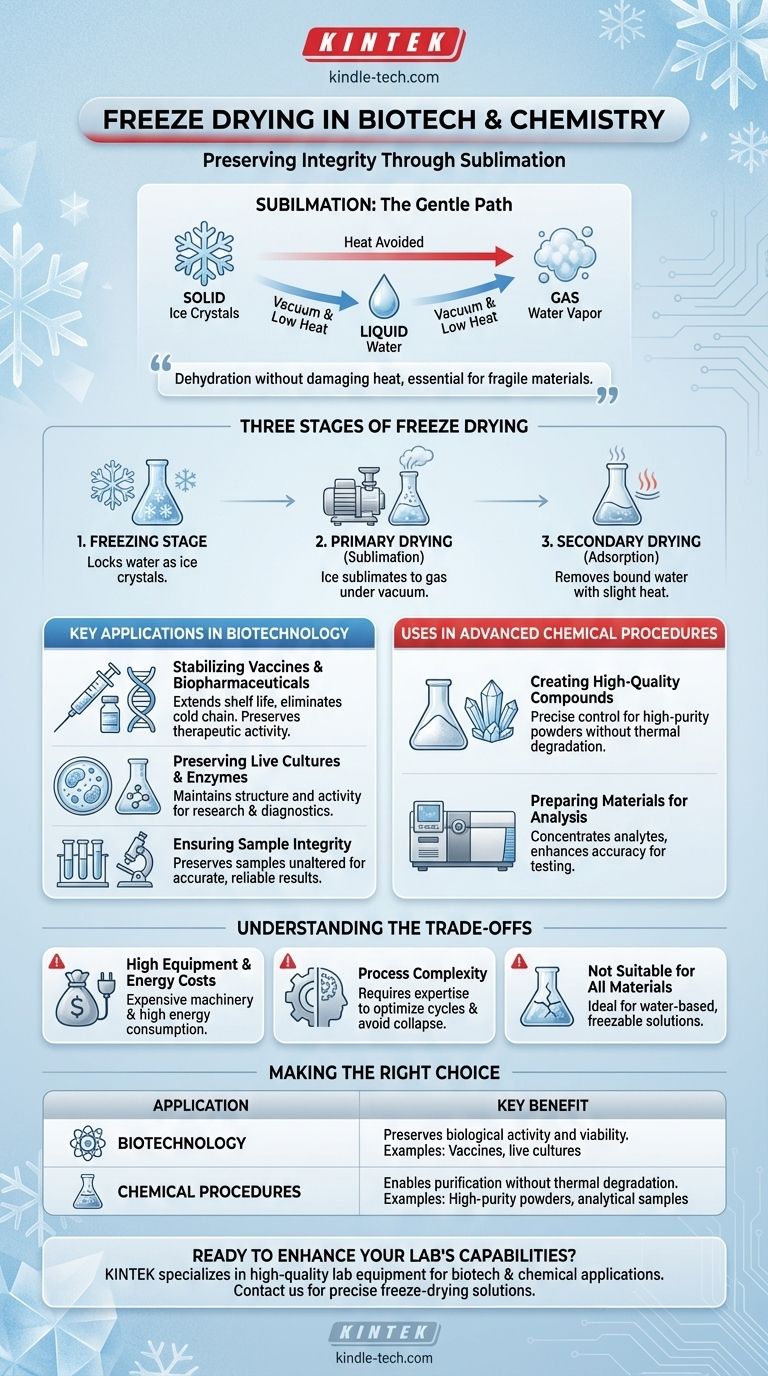

The Core Principle: Sublimation, Not Evaporation

Freeze drying works by fundamentally changing how water is removed from a product. Instead of using heat to evaporate liquid water, it uses a process called sublimation.

What is Sublimation?

Sublimation is the direct transition of a substance from a solid state to a gas state, completely skipping the liquid phase.

This gentle process avoids the high temperatures that can denature proteins, kill living cultures, or degrade sensitive chemical compounds.

The Three Stages of Freeze Drying

The process is meticulously controlled and occurs in three distinct phases to ensure the final product is stable and undamaged.

- The Freezing Stage: The material is completely frozen, typically to a very low temperature. This locks water molecules in place as ice crystals.

- The Primary Drying Stage (Sublimation): Under a deep vacuum, the pressure is lowered, and a small amount of heat is added. This gives the frozen water molecules enough energy to sublimate directly into a gas.

- The Secondary Drying Stage (Adsorption): After the ice is gone, some water molecules remain bound to the material. The temperature is slightly raised to break these bonds, and the vacuum pulls away the remaining moisture.

Key Applications in Biotechnology

In biotechnology, the goal is often to preserve biological activity. Freeze drying is the premier technology for achieving this.

Stabilizing Vaccines and Biopharmaceuticals

Many modern medicines, including vaccines, antibodies, and proteins, are inherently unstable in liquid form.

Freeze drying converts them into a stable powder, drastically extending shelf life and eliminating the need for constant refrigeration. This ensures their therapeutic activity is maintained until they are ready for use.

Preserving Live Cultures and Enzymes

Microbial cultures, enzymes, and other biological materials lose their viability if dried using conventional heat.

Lyophilization maintains their cellular structure and enzymatic activity, making it possible to store and transport these critical components for research, diagnostics, and industrial applications.

Ensuring Sample Integrity for Research

For laboratory analysis, it is crucial that samples remain unaltered between collection and testing.

Freeze drying preserves biological samples in a state of suspended animation. This ensures that experimental results are accurate, reliable, and reproducible, supporting major scientific breakthroughs.

Uses in Advanced Chemical Procedures

In chemical synthesis and analysis, the objective is often purity and stability.

Creating High-Quality Compounds

Freeze drying provides precise control over temperature and pressure, allowing for the gentle removal of solvents.

This is essential for producing high-purity, stable chemical powders without causing thermal degradation, which is a common problem with heat-sensitive molecules.

Preparing Materials for Analysis

By removing water, freeze drying can concentrate an analyte or prepare a compound in an ideal state for various analytical techniques. This enhances the accuracy and efficiency of chemical analysis.

Understanding the Trade-offs

While powerful, freeze drying is not a universal solution. It involves specific challenges that must be considered.

High Equipment and Energy Costs

The machinery required—including deep freezers, powerful vacuum pumps, and condensers—is expensive to purchase and operate. The process is also slow and consumes significant energy compared to other drying methods.

Process Complexity

Developing an effective freeze-drying cycle for a new product is a complex scientific endeavor. Each stage must be carefully optimized to avoid product collapse or loss of activity, which requires significant expertise.

Not Suitable for All Materials

The process is ideal for materials dissolved or suspended in water. It is generally not suitable for non-aqueous solvents or for materials that cannot withstand the initial freezing stage.

Making the Right Choice for Your Goal

To determine if freeze drying is the appropriate method, consider your primary objective.

- If your primary focus is long-term stability of a vaccine or protein: Freeze drying is the industry standard for preserving biological activity without requiring a constant cold chain.

- If your primary focus is producing a pure, heat-sensitive chemical powder: Lyophilization is an excellent method for removing solvents without risking thermal degradation of your final product.

- If your primary focus is preserving biological samples for research: Freeze drying is the best way to maintain the integrity of your samples, ensuring your analytical data is accurate and reliable.

Ultimately, freeze drying empowers scientists and engineers to preserve what is most fragile, turning unstable liquids into stable solids ready for the future.

Summary Table:

| Application Area | Key Benefit | Examples |

|---|---|---|

| Biotechnology | Preserves biological activity and viability | Vaccines, live cultures, enzymes, research samples |

| Chemical Procedures | Enables purification without thermal degradation | High-purity chemical powders, analytical samples |

Ready to enhance your lab's capabilities with precise freeze-drying solutions? KINTEK specializes in high-quality lab equipment and consumables for biotechnology and chemical applications. Our expertise ensures your sensitive materials—from vaccines to high-purity compounds—are preserved with maximum integrity and stability. Contact us today to discuss how we can support your specific laboratory needs and achieve superior results.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Isostatic Molding Pressing Molds for Lab

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Laboratory Single Horizontal Jar Mill

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does capacity affect the price of a lab freeze dryer? Find the Right Fit for Your Lab

- What problems should be avoided when using a lyophilizer? Prevent Product Collapse and Equipment Overload

- How does freeze drying benefit the cosmetics industry? Unlock Potent, Preservative-Free Formulas

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- How does freeze drying extend the shelf life of pharmaceutical products? Preserve Potency and Stability for Years